Offshore industries have been increasingly using fiberglass (FRP) products for various applications due to their numerous advantages over traditional materials. Fiberglass, also known as Glass Reinforced Plastic (GRP), is a composite material made from glass fibers embedded in a resin matrix. In this essay, we will discuss the reasons why offshore industries have been choosing FRP products over other materials.

Reasons why offshore industries use FRP products

Corrosion Resistance:

One of the main reasons for using FRP products in offshore industries is their excellent resistance to corrosion. Offshore environments are harsh, with exposure to saltwater, chemicals, and extreme weather conditions. FRP products are resistant to corrosion caused by saltwater, chemicals, and UV rays, making them an ideal material for offshore applications.

Lightweight:

FRP products are lightweight, making them easier to transport and install. This is particularly important in offshore industries where equipment and structures need to be transported to remote locations. The lightweight nature of FRP products also reduces the load on offshore platforms, reducing the risk of structural failure.

High Strength:

FRP products have high strength-to-weight ratios, making them ideal for applications where high strength is required. This is particularly important in offshore industries where equipment and structures need to withstand high winds, waves, and other environmental forces.

Low Maintenance:

FRP products require low maintenance and have a long service life. They do not need to be painted or treated to maintain their structural integrity, reducing maintenance costs and downtime.

Customization:

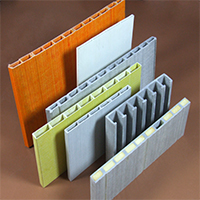

FRP products can be easily molded into complex shapes and sizes, making them ideal for custom applications. This allows offshore industries to design equipment and structures that are specifically suited to their needs, reducing costs and increasing efficiency.

Cost-Effective:

FRP products are cost-effective compared to traditional materials such as steel and aluminum. They are manufactured using a continuous process, reducing production costs and increasing efficiency. Additionally, the low maintenance costs and long service life of FRP products make them a cost-effective solution in the long term.

Environmentally Friendly:

FRP products are environmentally friendly, as they do not contain harmful chemicals or emit toxic fumes. This is particularly important in offshore industries, where the impact on the environment is a major concern.

In conclusion, offshore industries have been increasingly using FRP products due to their numerous advantages over traditional materials. FRP products are corrosion-resistant, lightweight, high strength, low maintenance, customizable, cost-effective, and environmentally friendly. These properties make FRP products an ideal material for various applications in offshore industries, including platforms, pipelines, and vessels. With the continued growth of the offshore industry, it is expected that the use of FRP products will continue to increase in the future.

info@unicomposite.com

info@unicomposite.com