Introduction

In industries where durability, safety, and reliability are non-negotiable, GRP open mesh grating has emerged as a revolutionary solution. This versatile material, composed of glass-reinforced plastic, is designed to meet the demands of heavy-duty environments while providing unmatched benefits over traditional materials like steel and aluminum. Whether in chemical plants, marine applications, or industrial flooring, GRP open mesh grating proves to be a game-changer. Let’s explore what makes it the best choice for these challenging settings.

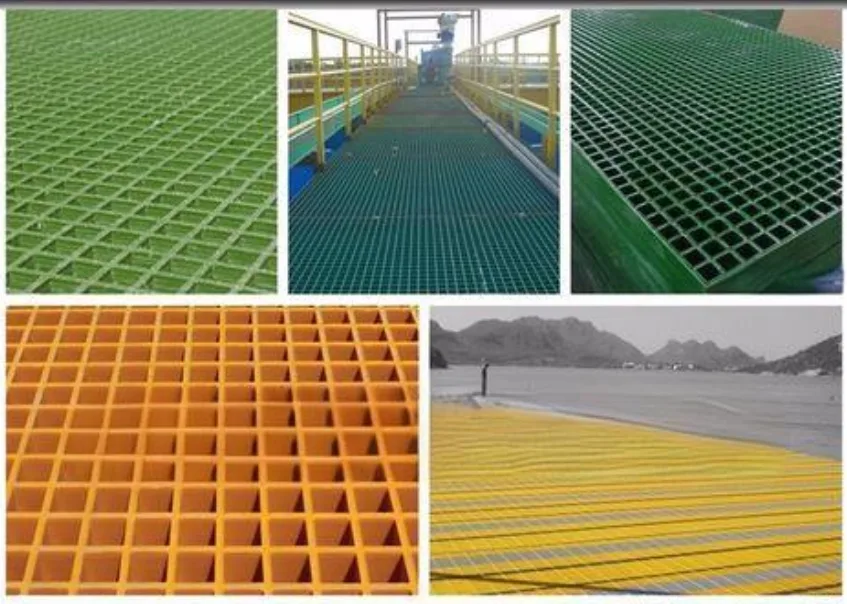

grp open mesh grating

What is GRP Open Mesh Grating?

GRP open mesh grating is crafted from a composite of glass fibers embedded in a durable resin matrix, resulting in a lightweight yet incredibly strong material. Its open mesh design ensures optimal drainage and airflow, making it ideal for environments prone to moisture or debris accumulation. The manufacturing process involves a combination of molding techniques to ensure consistency, quality, and durability.

Key features include:

- Corrosion resistance: Withstanding exposure to harsh chemicals and saltwater.

- Lightweight nature: Easy to transport and install.

- High strength-to-weight ratio: Ideal for heavy-duty applications.

Advantages of GRP Open Mesh Grating

Compared to traditional materials, GRP grating offers several advantages:

- Lightweight Yet Durable: GRP grating is much lighter than steel, making it easier to handle without compromising load capacity.

- Corrosion Resistance: Ideal for areas exposed to moisture, chemicals, or extreme temperatures.

- Non-Conductive Properties: Ensures safety in electrical and high-risk environments.

- Low Maintenance: Requires minimal upkeep compared to metals that need regular painting or anti-corrosion treatments.

- Customizability: Can be tailored in terms of size, shape, and color to suit specific applications.

Applications of GRP Open Mesh Grating

The versatility of GRP open mesh grating allows it to be used in various industries, such as:

- Industrial Flooring: Strong and durable for factories and warehouses.

- Marine Environments: Resistant to saltwater corrosion for docks and offshore platforms.

- Chemical Plants: Handles exposure to hazardous substances without degrading.

- Public Walkways: Slip-resistant surfaces ensure pedestrian safety.

GRP Open Mesh Grating vs. Traditional Materials

When compared to steel and aluminum, GRP grating stands out in several ways:

| Feature | Steel | Aluminum | GRP Grating |

|---|---|---|---|

| Weight | Heavy | Moderate | Lightweight |

| Corrosion Resistance | Low | Moderate | High |

| Maintenance Needs | High | Medium | Low |

| Cost | Moderate | High | Cost-Effective |

Durability in Heavy-Duty Environments

GRP open mesh grating is engineered to withstand heavy loads and harsh conditions. Its robust construction ensures longevity in high-traffic areas, and real-world examples from industries like shipping and construction validate its performance.

Non-Slip Surface Benefits

The non-slip surface of GRP grating makes it a top choice for safety-conscious environments. It complies with global safety standards and provides workers with a secure footing, even in wet and oily conditions.

Corrosion Resistance in GRP Open Mesh Grating

The corrosion resistance of GRP grating makes it indispensable in industries like chemical processing and wastewater treatment. Its resilience translates to longer service life and fewer replacements, saving costs in the long run.

Maintenance and Longevity

GRP grating requires minimal maintenance. Unlike metals that rust or wood that rots, it remains unaffected by environmental factors, offering decades of reliable service.

How to Choose the Right GRP Open Mesh Grating

When selecting GRP grating, consider these factors:

- Load-bearing capacity

- Application environment

- Size and thickness

- Anti-slip and fire-resistant options

Installation Process

Installing GRP grating is straightforward:

- Measure the installation area.

- Cut the grating to size using standard tools.

- Secure it in place with clamps or fasteners.

This process saves time and labor compared to traditional materials.

Cost-Effectiveness of GRP Open Mesh Grating

Although the upfront cost may be slightly higher than steel, the long-term savings in maintenance, replacement, and downtime make GRP the more economical choice.

Customization Options

GRP grating can be customized to suit unique requirements. Options include:

- Specific colors for visibility.

- Anti-slip coatings for additional safety.

- Fire-resistant finishes for hazardous environments.

Environmental Benefits of GRP Open Mesh Grating

GRP is environmentally friendly, thanks to its recyclability and reduced energy requirements during production. By choosing GRP, industries contribute to sustainability goals.

FAQs on GRP Open Mesh Grating

- How long does GRP grating last?

GRP grating can last 20–30 years with minimal maintenance. - Is GRP grating safe for marine applications?

Yes, its corrosion resistance makes it ideal for saltwater environments. - Can GRP grating support heavy loads?

Absolutely, it is designed to handle heavy-duty applications. - Does GRP grating require special tools for installation?

No, standard cutting and fastening tools are sufficient. - Is GRP environmentally sustainable?

Yes, it is recyclable and requires less energy to produce. - What maintenance does GRP grating need?

Periodic cleaning with water or mild detergents is sufficient.

Conclusion

GRP open mesh grating stands out as the best choice for heavy-duty environments due to its unparalleled strength, safety, and durability. It not only outperforms traditional materials but also offers significant cost savings and environmental benefits. For industries seeking a reliable, long-term solution, GRP grating is the ultimate answer. Ready to transform your flooring with GRP open mesh grating? Explore your options today!