Introduction

Fiberglass Reinforced Gratings (FRGs) are revolutionizing industries where durability and safety are paramount. Unlike traditional materials like steel or wood, FRGs offer a lightweight yet robust alternative designed to withstand the most demanding environments. Whether in industrial facilities, commercial buildings, or marine applications, their unique properties make them the go-to solution for infrastructure challenges. This article explores why FRGs stand out for their unparalleled durability and safety benefits.

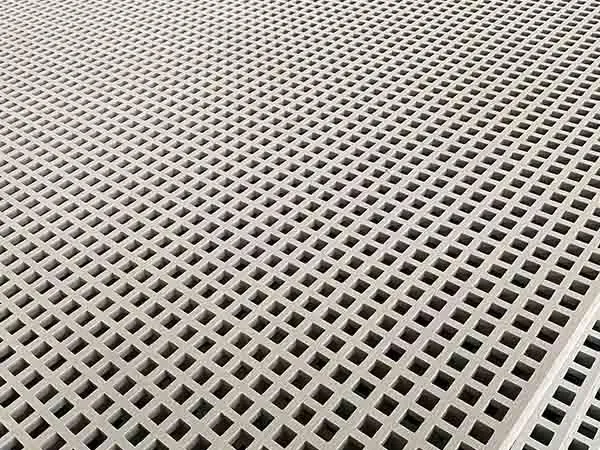

fiberglass reinforced gratings

What Are Fiberglass Reinforced Gratings?

Overview of Material Composition

Fiberglass Reinforced Gratings are constructed using fiberglass strands embedded in a resin matrix. This combination provides exceptional strength and resilience while maintaining a lightweight structure. The reinforcement process ensures the gratings can handle heavy loads and resist wear and tear over time.

Key Features of FRGs

- Corrosion Resistance: FRGs resist chemical and environmental corrosion, making them ideal for harsh settings.

- Non-Conductive Properties: Unlike metal gratings, FRGs do not conduct electricity, enhancing safety in electrical environments.

- Lightweight Yet Strong: Despite their light weight, FRGs offer superior load-bearing capacity compared to traditional materials.

Why Fiberglass Reinforced Gratings Excel in Durability

Resistance to Harsh Environments

FRGs are engineered to endure extreme conditions, from salty marine air to corrosive chemicals. Their inherent resistance to rust and degradation makes them a reliable choice for industries like oil and gas, chemical processing, and wastewater treatment.

Long Lifespan with Minimal Maintenance

Traditional materials like steel require regular upkeep to combat rust and wear, but FRGs drastically reduce maintenance costs. Their durability ensures a long service life, even in environments that would quickly deteriorate other materials.

Structural Integrity Under Load

Despite their lightweight nature, FRGs boast impressive load-bearing capabilities. This combination of strength and flexibility makes them suitable for heavy-duty environments such as warehouses, oil rigs, and transportation hubs.

Enhancing Safety with Fiberglass Reinforced Gratings

Slip Resistance for Accident Prevention

One of the standout safety features of FRGs is their slip-resistant surface, which significantly reduces the risk of workplace accidents. In wet, oily, or icy conditions, FRGs provide secure footing, protecting workers and the public alike.

Fire Retardant Properties

Many FRGs are manufactured with fire-resistant resins that comply with strict safety standards. This quality makes them a preferred choice for facilities where fire hazards are a concern, such as power plants and industrial kitchens.

Non-Conductive and Non-Sparking Qualities

In environments where electrical and explosive hazards exist, the non-conductive and non-sparking nature of FRGs offers unparalleled safety. This makes them indispensable for industries like mining, energy, and manufacturing.

Industries That Rely on Fiberglass Reinforced Gratings

Industrial Applications

FRGs are extensively used in chemical plants, oil refineries, and power plants, where their resistance to chemicals and heat ensures longevity and safety.

Commercial Use Cases

In commercial settings, FRGs are popular for walkways, platforms, and stair treads. Their lightweight yet sturdy design allows for easy installation and long-lasting performance.

Marine and Offshore Applications

In the marine industry, FRGs are used for docks, ship decks, and offshore platforms. Their resistance to saltwater corrosion makes them ideal for these high-moisture environments.

Key Considerations When Choosing Fiberglass Reinforced Gratings

Customization Options

FRGs are available in various sizes, colors, and surface finishes, allowing customization to meet specific needs. Whether it’s a particular load requirement or aesthetic preference, FRGs can be tailored to fit.

Cost-Effectiveness

While the initial cost of FRGs may be higher than traditional materials, their low maintenance and long lifespan offer substantial savings over time, making them a cost-effective choice.

Compliance and Certifications

When selecting FRGs, ensure they meet industry standards such as OSHA or ASTM certifications. These standards guarantee quality and safety for your applications.

Conclusion

Fiberglass Reinforced Gratings are setting new standards in durability and safety across a range of industries. Their resistance to harsh conditions, low maintenance requirements, and safety-enhancing features make them an invaluable asset for modern infrastructure. As industries continue to prioritize efficiency and safety, FRGs stand out as the ultimate solution.

Take the next step today! Explore fiberglass reinforced gratings for your projects and consult with trusted suppliers to discover how they can revolutionize your operations.