Introduction

In today’s evolving construction landscape, materials that are both lightweight and durable have become essential, particularly for applications exposed to harsh environments or requiring high strength-to-weight ratios. Among these materials, fiberglass equal leg angle has emerged as a top choice, particularly in sectors like construction, electrical, and marine industries. This article delves into the many benefits, applications, and reasons why fiberglass equal leg angles are a smart choice for various structural applications.

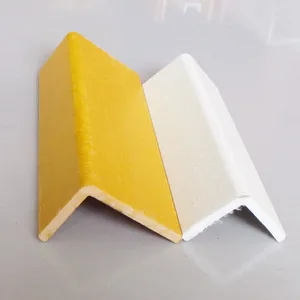

fiberglass equal leg angle

1. What Is Fiberglass Equal Leg Angle?

Fiberglass equal leg angle is a composite structural material typically composed of glass fibers bound in a resin matrix. Unlike metals, which have uniform properties, fiberglass consists of multiple components that contribute to its unique qualities. The term “equal leg angle” refers to the L-shaped cross-section with legs of equal length. This structural shape is favored in applications requiring stability and load-bearing capacity without the high weight of metals.

2. The Manufacturing Process

Fiberglass equal leg angles are manufactured primarily through the pultrusion process, a method where continuous strands of glass fiber are pulled through a resin bath and then shaped and hardened into a specific form. This process allows for consistent structural quality and high resistance to corrosion, which is why fiberglass products are often used in corrosive or high-humidity environments.

3. Key Advantages of Fiberglass Equal Leg Angle

Fiberglass equal leg angle offers several key advantages:

- Corrosion resistance: Unlike steel, fiberglass doesn’t rust.

- Lightweight: Easier to handle and install.

- High durability: Resists wear even in tough environments.

- Non-conductive: Safe for electrical applications.

- Low maintenance: Long-lasting with minimal upkeep.

4. Comparison with Steel Equal Leg Angle

While steel is known for its high load-bearing capacity, it also brings the challenges of weight and vulnerability to corrosion. Fiberglass, on the other hand, provides:

- Weight advantage: Easier to transport and install.

- Corrosion resistance: Outlasts steel in humid or salt-laden conditions.

- Lower maintenance: Steel requires regular painting or coating to prevent rust. Fiberglass might have a higher upfront cost but proves more economical over time due to these benefits.

5. Structural Applications of Fiberglass Equal Leg Angle

Fiberglass equal leg angles are used widely in applications where traditional materials may fall short. Some examples include:

- Construction: Structural supports, bracing, and framework.

- Industrial settings: Chemical-resistant structures, such as tank supports.

- Marine environments: Docks, piers, and other areas in constant contact with water.

- Electrical and utility sectors: Non-conductive supports and enclosures.

6. Durability and Lifespan

Fiberglass is renowned for its longevity. These angles are designed to withstand exposure to UV rays, moisture, and other environmental factors without degrading. This durability makes them ideal for applications where long-term performance is essential, offering a lifespan significantly longer than that of untreated steel.

7. Lightweight and High Strength-to-Weight Ratio

One of fiberglass’s standout features is its high strength relative to its weight. In situations where both strength and lightness are crucial, fiberglass outperforms most metals, which are often heavier and more cumbersome to install. This advantage leads to reduced transportation costs and easier handling.

8. Corrosion Resistance

Fiberglass’s natural resistance to corrosion from chemicals, saltwater, and acidic or alkaline substances makes it the preferred choice for environments where steel and other metals may deteriorate quickly. This resilience is especially beneficial for marine and industrial applications where prolonged exposure to corrosive elements is common.

9. Electrical and Thermal Non-Conductivity

Fiberglass does not conduct electricity, making fiberglass equal leg angles highly suitable for applications around high-voltage areas or sensitive electrical equipment. Its thermal insulation properties also make it effective in environments where exposure to extreme temperatures is possible, without the risk of warping or melting.

10. Versatility in Design and Customization

One of the practical benefits of fiberglass is that it can be customized in color, size, and length to fit project-specific needs. This flexibility allows architects, engineers, and builders to work with materials that precisely match their design requirements, adding to the material’s versatility.

11. Cost-Effectiveness

Although the initial cost of fiberglass equal leg angles may be higher than steel, it proves to be more cost-effective over the product’s lifecycle. Factors such as reduced maintenance costs, minimal need for protective coatings, and a longer lifespan contribute to significant savings in the long run.

12. Environmental Impact and Sustainability

As industries focus on sustainability, fiberglass has emerged as an eco-friendly choice. Its extended lifespan reduces the need for replacement, contributing to less waste. Additionally, many fiberglass products can be recycled or repurposed, making it a sustainable option for environmentally conscious projects.

13. Choosing the Right Fiberglass Equal Leg Angle

When selecting a fiberglass equal leg angle, consider the following:

- Load-bearing capacity: Ensure the angle can support anticipated loads.

- Environmental conditions: For corrosive settings, ensure the product has a suitable resin coating.

- Industry standards: Compliance with industry standards ensures quality and safety.

14. Installation and Maintenance

Fiberglass is straightforward to install due to its light weight. Once in place, these structures require little upkeep. A simple periodic inspection is often sufficient to ensure the material remains in excellent condition, further adding to the material’s cost-effectiveness.

15. Frequently Asked Questions (FAQs)

Q1: How strong is fiberglass compared to steel?

A: Fiberglass has a high strength-to-weight ratio, meaning it provides strong support relative to its light weight, but it may not be as strong as steel in certain heavy-load applications.

Q2: Can fiberglass equal leg angles be used outdoors?

A: Yes, they’re ideal for outdoor applications due to their resistance to moisture, UV rays, and harsh weather.

Q3: Are fiberglass angles safe to use around electrical equipment?

A: Absolutely. Fiberglass is non-conductive, making it an excellent choice for electrical installations.

Q4: How long does fiberglass last compared to steel?

A: With proper care, fiberglass often lasts longer than steel, especially in corrosive environments.

Q5: What are the customization options for fiberglass angles?

A: Fiberglass can be manufactured in a variety of colors, sizes, and lengths to meet project-specific requirements.

Q6: Is fiberglass more expensive than steel?

A: Initially, fiberglass can be more expensive but proves more economical over time due to reduced maintenance and replacement costs.

Conclusion

Fiberglass equal leg angles offer an impressive array of benefits that make them an excellent choice for structural applications across numerous industries. Whether for construction, marine, or electrical projects, this material provides an optimal combination of durability, lightness, and resistance to environmental stressors. With low maintenance needs and a long lifespan, fiberglass equal leg angles are a practical and cost-effective choice for those seeking sustainable, resilient solutions in modern design and engineering.

info@unicomposite.com

info@unicomposite.com