In the world of industrial materials and construction, fiberglass grating has gained significant popularity due to its versatility, durability, and cost-effectiveness. If you’re a buyer looking to invest in wholesale fiberglass grating, this ultimate guide is here to provide you with all the information you need to make an informed decision. From understanding the benefits of fiberglass grating to selecting the right type and supplier, we’ve got you covered.

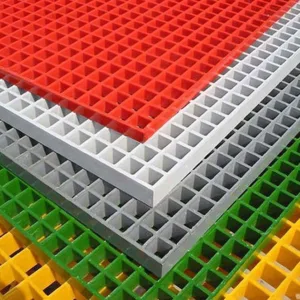

wholesale fiberglass grating

Introduction to Fiberglass Grating

Fiberglass grating, also known as FRP (Fiber-Reinforced Plastic) grating, is a versatile and durable material used in various industries such as construction, oil and gas, chemical processing, and marine applications. It is composed of reinforced fiberglass strands embedded in a resin matrix, making it lightweight yet incredibly strong. Unlike traditional materials like steel or wood, fiberglass grating offers a range of benefits that make it a popular choice among buyers.

Advantages of Fiberglass Grating

Lightweight and Easy to Install

One of the key advantages of fiberglass grating is its lightweight nature. This makes transportation and installation significantly easier and more cost-effective than heavy alternatives like steel grating. Whether you are working on a small-scale project or a large industrial site, the reduced weight of fiberglass grating can save you time and resources.

Corrosion Resistance

Fiberglass grating is inherently resistant to corrosion and rust. This resistance is especially crucial in environments where exposure to chemicals or moisture is common. Unlike metal grating, fiberglass doesn’t require extensive maintenance to prevent corrosion, making it a long-lasting and reliable choice.

High Strength-to-Weight Ratio

Despite being lightweight, fiberglass grating boasts a high strength-to-weight ratio. It can withstand heavy loads and provides excellent support for various applications. Whether you need to support heavy machinery or create a secure walkway, fiberglass grating can handle the job.

Anti-Slip Properties

Safety is paramount in many industries. Fiberglass grating is designed with anti-slip surfaces, reducing the risk of accidents and injuries. This feature makes it ideal for use in areas where employees or workers need secure footing, even in wet or oily conditions.

Types of Fiberglass Grating

There are two main types of fiberglass grating available in the market: molded fiberglass grating and pultruded fiberglass grating.

Molded Fiberglass Grating

Molded fiberglass grating is created by layering fiberglass strands in a mold and saturating them with resin. This process results in a grating with excellent corrosion resistance and durability. It is often used in applications that require a high level of chemical resistance.

Pultruded Fiberglass Grating

Pultruded fiberglass grating is manufactured by pulling fiberglass strands through a resin bath and then through a heated die. This process results in a grating with exceptional strength and stiffness. It is commonly used in applications where high load-bearing capacity is essential.

Choosing the Right Grating for Your Needs

Selecting the right type of fiberglass grating is crucial to the success of your project. Consider the following factors when making your decision:

Load-Bearing Capacity

Determine the maximum load your grating will need to support. Different types of fiberglass grating have varying load-bearing capacities, so ensure you choose one that meets your requirements.

Chemical Resistance

Evaluate the chemicals present in your environment. Molded fiberglass grating is better suited for highly corrosive environments, while pultruded grating may be sufficient for less harsh conditions.

Anti-Slip Properties

If safety is a primary concern, prioritize grating with excellent anti-slip properties. This is particularly important in areas prone to moisture or oil.

Environmental Factors

Consider the temperature, UV exposure, and humidity levels of your application site. Some grating types may be better suited to extreme conditions than others.

Finding a Reliable Supplier

Once you’ve determined the type of fiberglass grating you need, it’s essential to find a reliable supplier. Look for a supplier with a proven track record, excellent customer reviews, and a commitment to quality, like Unicomposite.

Quality Assurance and Standards

Ensure that the fiberglass grating you purchase meets industry standards and certifications. This guarantees that you are getting a high-quality product that will perform as expected.

Installation and Maintenance

Proper installation and regular maintenance are essential for maximizing the lifespan of your fiberglass grating. Follow the manufacturer’s guidelines for installation and establish a maintenance schedule to keep your grating in top condition.

Cost Considerations

While fiberglass grating offers long-term cost savings due to its durability and low maintenance requirements, it’s essential to consider your budget when making a purchase. Compare quotes from different suppliers to find the best value for your project.

Applications of Fiberglass Grating

Fiberglass grating finds use in a wide range of applications, including:

- Industrial flooring

- Walkways and platforms

- Stair treads

- Chemical processing plants

- Oil and gas platforms

- Marine environments

- Food processing facilities

Its versatility and adaptability make it a go-to choice for various industries.

Comparing Fiberglass Grating to Other Materials

To make an informed decision, it’s beneficial to compare fiberglass grating to other materials like steel or wood. Consider factors such as cost, maintenance, and performance in your specific application.

Case Studies

Explore real-world examples of projects that have successfully utilized fiberglass grating. Case studies can provide valuable insights into the material’s performance and benefits.

Customer Reviews

Reading customer reviews and testimonials can help you gauge the satisfaction levels of previous buyers. Look for feedback on product quality, supplier reliability, and overall experience.

FAQs

1. Is fiberglass grating suitable for outdoor use?

- Yes, fiberglass grating is designed to withstand outdoor conditions, including exposure to UV rays and moisture.

2. How does fiberglass grating compare to steel grating in terms of cost?

- While the initial cost of fiberglass grating may be higher than steel, the long-term savings in maintenance and corrosion resistance often make it a more cost-effective choice.

3. Can fiberglass grating be customized for specific applications?

- Yes, many fiberglass grating suppliers offer customization options to tailor fiberglass grating to your unique needs.

4. What is the lifespan of fiberglass grating?

- With proper installation and maintenance, fiberglass grating can last for decades.

5. Are there any safety standards for fiberglass grating installation?

- Yes, industry standards exist to ensure the safe installation of fiberglass grating. Always follow manufacturer guidelines and relevant safety regulations.

Conclusion

Wholesale fiberglass grating is an excellent investment for buyers seeking durable, corrosion-resistant, and versatile materials. By understanding the types, benefits, and considerations associated with fiberglass grating, you can confidently choose the right product for your specific needs. Whether you’re working on a construction project or maintaining an industrial facility, fiberglass grating is a reliable choice that will stand the test of time.