Introduction

Fiberglass grating is widely used in industrial settings due to its durability, corrosion resistance, and lightweight construction. However, no material lasts forever, and knowing when to replace fiberglass grating is crucial for maintaining a safe work environment. Ignoring the signs of deteriorating grating can lead to accidents, increased maintenance costs, and potential legal liabilities. This article outlines 5 clear signs indicating when replacement is necessary, helping you maintain safety and efficiency.

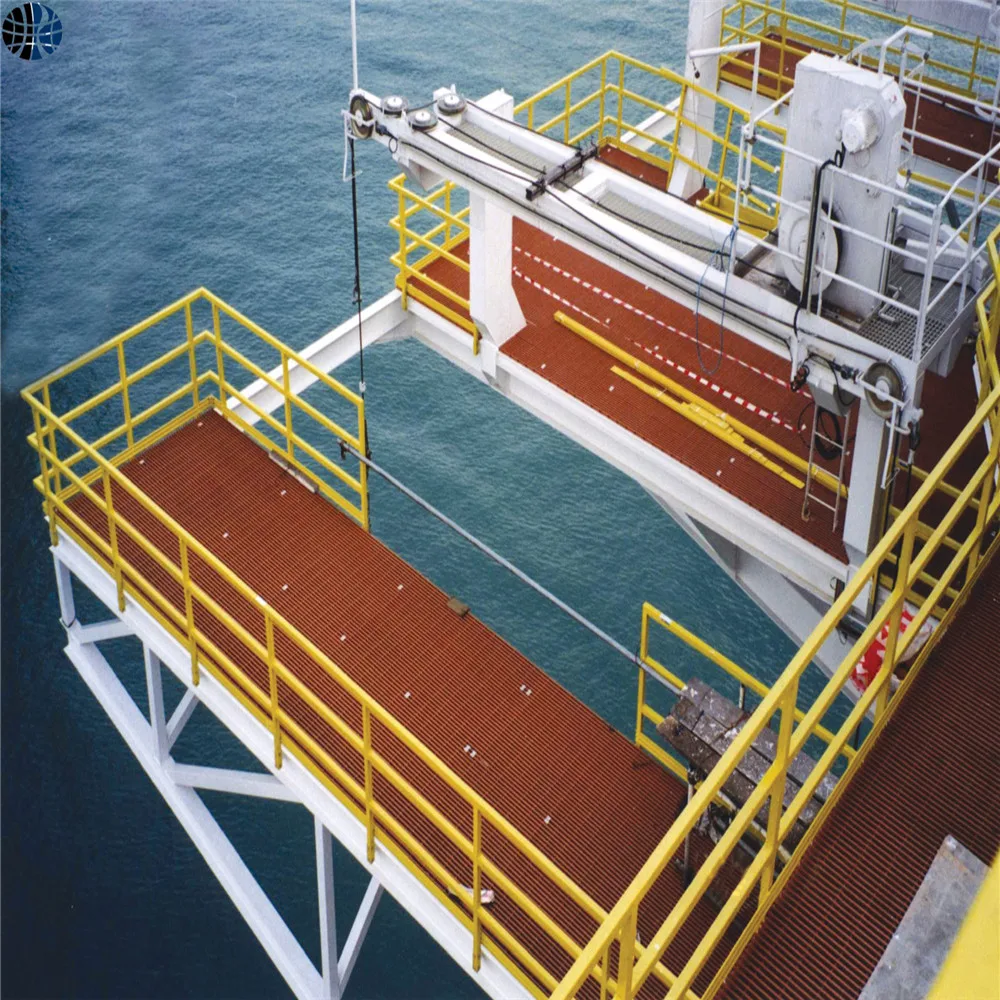

when to replace fiberglass grating

5 Clear Signs You Shouldn’t Ignore When to Replace Fiberglass Grating

1. Visible Cracks and Breakage

One of the earliest signs indicating the need for replacement is visible cracking or breakage. Fiberglass grating withstands heavy loads and impacts but, over time, stress fractures can develop.

Risks: Cracks significantly weaken grating structure, leading to potential failure under load.

Inspection tips:

Perform regular visual checks every month.

Inspect closely around fasteners, corners, and edges.

Replace immediately if cracks longer than an inch appear.

According to industry safety standards, even minor cracks can reduce load-bearing capacity by up to 30%, emphasizing the urgency of replacement.

2. Surface Corrosion and Wear

Fiberglass grating is corrosion-resistant, but constant exposure to chemicals, moisture, and environmental factors gradually degrades its surface.

Corrosion indicators:

Surface discoloration or flaking.

Rough textures or pitting.

Safety hazards:

Increased slipping risk.

Decreased structural integrity.

Inspection recommendation: Schedule inspections at least quarterly in chemically aggressive environments.

Replacing grating at the first signs of corrosion helps prevent workplace incidents and ensures compliance with safety regulations.

3. Increased Deflection or Sagging

Fiberglass grating should remain rigid under load. Any noticeable deflection or sagging signals significant structural weakening.

Signs of deflection:

Visible bowing when walked upon.

Changes in original shape or level.

Acceptable limits: Typically, deflection exceeding 1/4 inch per foot of span indicates severe compromise.

Consequences:

Increased risk of tripping or falling.

Potential catastrophic structural failure.

Regular load-testing helps detect deflection early, facilitating timely replacement and reducing hazards.

4. Exposure to Harsh Chemicals or Extreme Conditions

Certain environments accelerate the deterioration of fiberglass grating. Continuous exposure to harsh chemicals, intense heat, freezing temperatures, or saltwater significantly shortens its lifespan.

Common conditions accelerating damage:

Chemical plants (acids, alkalis).

Marine settings (saltwater corrosion).

Extreme temperature fluctuations.

Preventive measures:

Apply protective chemical-resistant coatings.

Increase frequency of inspections in these environments.

If your grating operates in extreme conditions, consider shorter replacement intervals to maintain safety and reliability.

5. Exceeding the Expected Lifespan

Fiberglass grating typically has a lifespan of about 15–25 years, depending on environmental and operational conditions. Once grating approaches or exceeds this range, replacement becomes essential.

Factors influencing lifespan:

Quality of initial materials.

Frequency and weight of loads.

Environmental conditions.

Maintenance tips:

Document installation dates clearly.

Set reminders for regular maintenance checks.

Proactive replacement before structural issues arise is more cost-effective, as reactive repairs and replacements tend to be more expensive and disruptive.

Conclusion

Knowing when to replace fiberglass grating is critical for maintaining workplace safety, preventing costly downtime, and extending the lifespan of your facilities. Watch for clear signs like cracks, corrosion, deflection, exposure to harsh conditions, and aging beyond expected lifespan.

Take action early to minimize risks and save on long-term costs. Consider scheduling a professional assessment of your fiberglass grating regularly to ensure continuous safety and compliance.

Have experiences to share? Comment below or subscribe for more maintenance insights and safety guidelines!