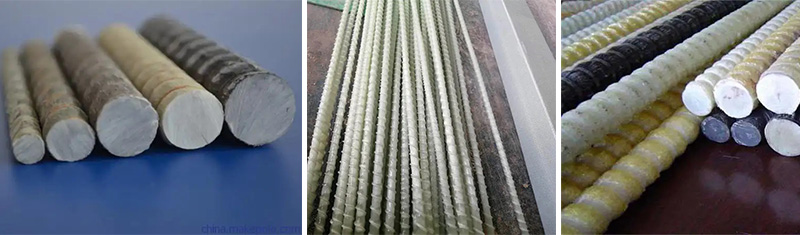

Fiberglass rebar is a kind of reinforcing material. It is a composite material made of synthetic resin as the matrix material and mixed with an appropriate amount of auxiliary agents. Compared with ordinary steel rebar, it has many advantages. Its absolute anti-corrosion performance, thermal insulation, resistance to Features such as high tensile strength, ease of cutting, and lightweight play an important role in major civil engineering projects.

What are the benefits of fiberglass rebar?

- High tensile strength: The tensile strength of fiberglass rebar is better than that of ordinary rebar, which is 20% higher than that of rebar of the same specification, and has good fatigue resistance.

- Lightweight: The quality of fiberglass rebar is only 1/4 of the same volume of rebar, and the density is between 1.5 and 1.9 (g/cm3).

- Strong corrosion resistance: The corrosion resistance of chemicals such as acid and alkali can resist the corrosion of chloride ions and low pH value solutions, especially the corrosion resistance of carbon compounds and chlorine compounds.

- Strong material bonding: The thermal expansion coefficient of FRP rebar is closer to that of cement than steel because the bonding force of glass fiber rebar and concrete is stronger.

- Strong designability: The elastic modulus of FRP rebar is stable, the size is stable under thermal stress, the bending and other shapes can be thermoformed arbitrarily, and the safety performance is good. Collision does not produce sparks.

- Strong magnetic wave permeability: FRP rebar is a kind of non-magnetic material, and it does not need to be demagnetized in non-magnetic or electromagnetic concrete components.

- Convenience in construction: fiberglass rebar can be produced in standard and non-standard parts of various sections and lengths according to user requirements, and non-metal tensioning belts can be used for on-site binding, which is easy to operate.

The product characteristics of fiberglass rebar make it adaptable to complex construction environments, and fiberglass rebar can be used to replace traditional rebar materials in highways, bridges, airports, docks, stations, water conservancy projects, underground engineering and other fields.