Introduction to Unequal Leg Fiberglass Angles

In the world of construction, materials that offer both durability and flexibility are crucial for building safe, long-lasting structures. One such material that has gained popularity in recent years is unequal leg fiberglass angles. These specially designed components are increasingly being used in a wide variety of construction applications, from reinforcing structures to supporting electrical infrastructure.

Fiberglass, a material known for its strength, lightweight properties, and corrosion resistance, has proven to be a valuable alternative to traditional metals in many industries. The “unequal leg” design refers to the two legs of the angle being of different lengths, providing more versatile options for specific structural needs. But what exactly makes unequal leg fiberglass angles so beneficial, and why should construction professionals consider them over more conventional materials? This article delves into the many uses, benefits, and applications of unequal leg fiberglass angles in the construction industry.

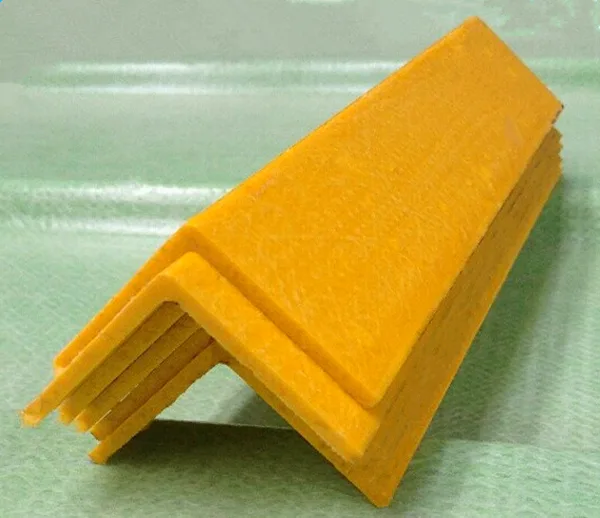

unequal leg fiberglass angle

What Is an Unequal Leg Fiberglass Angle?

An unequal leg fiberglass angle is a structural component used in construction, typically designed in an “L” shape but with legs of different lengths. These angles are made from fiberglass-reinforced plastic (FRP), which is a composite material consisting of a plastic resin reinforced with glass fibers. The unequal leg aspect refers to the two sides of the angle being of unequal length, offering a variety of benefits in terms of design flexibility and functionality.

Fiberglass angles, in general, are known for being both strong and lightweight. However, unequal leg fiberglass angles offer even more advantages in specific applications. For example, the longer leg can be used to bear more weight, while the shorter leg can be used for additional reinforcement or to secure the angle more easily within a structure.

Difference Between Equal and Unequal Leg Angles

The main difference between equal leg and unequal leg angles is the leg length. Equal leg angles, as the name suggests, have two sides that are the same length, forming a more symmetrical “L” shape. While this symmetry can be advantageous in certain applications, unequal leg angles provide more versatility. The uneven design allows for better customization, making them ideal for situations where a different load distribution or specific structural configuration is required.

The Advantages of Using Fiberglass Angles in Construction

Fiberglass has become an increasingly popular material in construction due to its impressive range of properties that are beneficial to both engineers and builders. Let’s explore the advantages of using fiberglass angles, particularly in unequal leg designs.

Lightweight and Durability

One of the primary benefits of fiberglass angles is their lightweight nature. Compared to metal components like steel or aluminum, fiberglass is much easier to handle and transport, reducing labor costs and installation time. Despite being lightweight, fiberglass is highly durable. It has an excellent strength-to-weight ratio, meaning it can withstand significant stress and load-bearing tasks without compromising its integrity.

Corrosion Resistance

Fiberglass is naturally resistant to corrosion, which makes it an excellent choice for use in harsh environments where other materials like steel would quickly degrade. This corrosion resistance is particularly valuable in construction projects near coastal areas or in industrial settings where chemicals or moisture might cause metals to rust or corrode. As a result, fiberglass angles offer a longer lifespan, saving on maintenance and replacement costs.

Thermal Insulation Properties

Fiberglass materials also have thermal insulation properties, making them ideal for projects where temperature control is important. Unlike metal, which can conduct heat and cold, fiberglass helps maintain stable temperature conditions. This can be especially beneficial in electrical or telecommunications installations, where maintaining temperature control can prevent damage to sensitive equipment.

Cost-Effectiveness and Longevity

While fiberglass may come at a higher initial cost compared to some traditional materials, its long-term benefits make it a cost-effective choice for many construction projects. The longevity of fiberglass, due to its corrosion resistance, low maintenance requirements, and strength, means that structures built with fiberglass angles can last for decades without needing significant repairs.

When compared to metals like steel, fiberglass angles also present a lower total cost of ownership. This is especially true when considering the reduced need for regular maintenance, as fiberglass does not require painting or coating to prevent corrosion, as metals do.

Applications of Unequal Leg Fiberglass Angles

Unequal leg fiberglass angles have found use in a wide range of applications across various sectors. Below are some of the most common areas where they are employed:

Structural Reinforcement

In construction, fiberglass angles are often used for reinforcing structures. The unequal leg design provides enhanced flexibility, enabling engineers to address specific load-bearing requirements and customize angles for unique design needs. Whether it’s used to reinforce beams, support columns, or frame walls, fiberglass angles offer the strength and stability required without adding excessive weight.

Supports for Industrial and Commercial Infrastructure

Fiberglass angles are also widely used in the industrial and commercial sectors. They are often employed in the creation of supporting frameworks for large equipment, walkways, and platforms. Their resistance to corrosion makes them particularly suitable for outdoor or coastal environments, where other materials might not hold up as well. Additionally, the ability to customize the leg lengths allows for more adaptable installations, making them ideal for projects that require specific configurations.

Use in Bridges and Walkways

Fiberglass angles are especially useful in the construction of bridges and walkways. The unequal leg design can be tailored to meet specific structural needs, providing enhanced support and reinforcement where necessary. For example, the longer leg of the angle might be used to support heavy loads, while the shorter leg can help secure the angle in place.

Since fiberglass is resistant to corrosion, these angles are perfect for outdoor structures exposed to the elements, where rust and degradation could otherwise become a problem. Walkways, pedestrian bridges, and even industrial platforms can benefit from the lightweight yet robust nature of fiberglass angles.

Role in Electrical and Telecommunications Infrastructure

Fiberglass angles also play an important role in electrical and telecommunications infrastructure, where they are often used to support wiring, cables, and other equipment. The corrosion-resistant properties of fiberglass are especially valuable in these settings, where cables and wires may be exposed to the elements, and metal components might degrade over time.

By providing a durable, long-lasting framework for cables and wires, fiberglass angles help ensure that electrical systems remain safe and functional for years to come.

How to Choose the Right Unequal Leg Fiberglass Angle for Your Project

Choosing the right unequal leg fiberglass angle for your construction project depends on several factors. Below are key considerations when selecting the appropriate angle for your needs:

Factors to Consider: Load Capacity, Size, Shape

When selecting fiberglass angles, it is important to consider the load-bearing capacity required for your specific application. Ensure that the angle you choose can support the anticipated weight or pressure. Additionally, pay attention to the size and shape of the angle. The unequal leg design may provide the flexibility needed to support different parts of the structure, but it’s important to choose angles that are appropriately sized for your project.

Material Composition and Strength

Fiberglass angles are typically made from a combination of resin and glass fibers, but there are different types of resins available. Epoxy resin offers superior strength and durability, while polyester resin is more cost-effective. When choosing your fiberglass angle, ensure that the material composition matches the environmental demands and structural requirements of your project.

Customization and Sizing Options

Fiberglass angles are highly customizable. Manufacturers can create angles in a variety of sizes, shapes, and strengths to meet specific project requirements. Whether you need a particular length, angle, or weight capacity, fiberglass angles can be tailored to suit your needs.

Installation Process for Unequal Leg Fiberglass Angles

Installing unequal leg fiberglass angles requires careful planning and attention to detail to ensure that the structure is both secure and stable. Proper tools such as drills, saws, and fasteners are necessary for accurate cutting and secure installation. Additionally, ensure that the angles are aligned correctly to avoid misalignment, which could compromise the structural integrity.

Safety Considerations During Installation

As with any construction task, safety should always be a priority during the installation of fiberglass angles. Workers should wear protective gear, including gloves and goggles, to avoid injury from sharp edges and fiberglass dust. Additionally, ensure that angles are properly secured during installation to avoid accidental shifts or movements.

Common Mistakes to Avoid When Using Unequal Leg Fiberglass Angles

While fiberglass angles are generally easy to work with, there are some common mistakes that can occur during installation or selection:

- Incorrect sizing: Choosing an angle that is too large or too small for the load requirements can lead to structural failure.

- Poor material selection: Not choosing the appropriate resin type or fiberglass reinforcement can compromise the angle’s strength and durability.

- Misalignment: Failing to properly align the angles during installation can lead to instability in the structure.

Environmental Benefits of Fiberglass Angles

Fiberglass angles are not only a great choice for durability and strength but also offer significant environmental benefits. As a sustainable material, fiberglass can be recycled, reducing its overall environmental impact. Additionally, fiberglass production has a lower carbon footprint compared to metals like steel, making it an eco-friendly choice for modern construction projects.

The Future of Fiberglass Angles in Construction

As construction practices evolve and sustainability becomes an even greater focus, fiberglass materials will continue to play an important role. Innovations in fiberglass technology, such as the development of new resin types and improved manufacturing processes, will likely make fiberglass angles even more versatile and cost-effective in the years to come.

Conclusion

Unequal leg fiberglass angles offer a wide array of benefits for modern construction projects. Their lightweight, corrosion-resistant, and durable nature makes them a smart choice for everything from structural reinforcement to supporting electrical infrastructure. With their customizable design and ease of installation, these angles provide the versatility needed to meet the demands of complex construction projects. Whether you are working on industrial, commercial, or residential applications, unequal leg fiberglass angles can help ensure that your structures are built to last.