Introduction

FRP leg angles—fiberglass reinforced plastic leg angles—are essential components in various industries, from construction to marine engineering. Known for their lightweight properties, resistance to corrosion, and high strength, FRP leg angles have become a popular choice for engineers and builders alike. In this article, we will explore the benefits, applications, and key considerations when using FRP leg angles, and why they are an ideal solution for many structural needs.

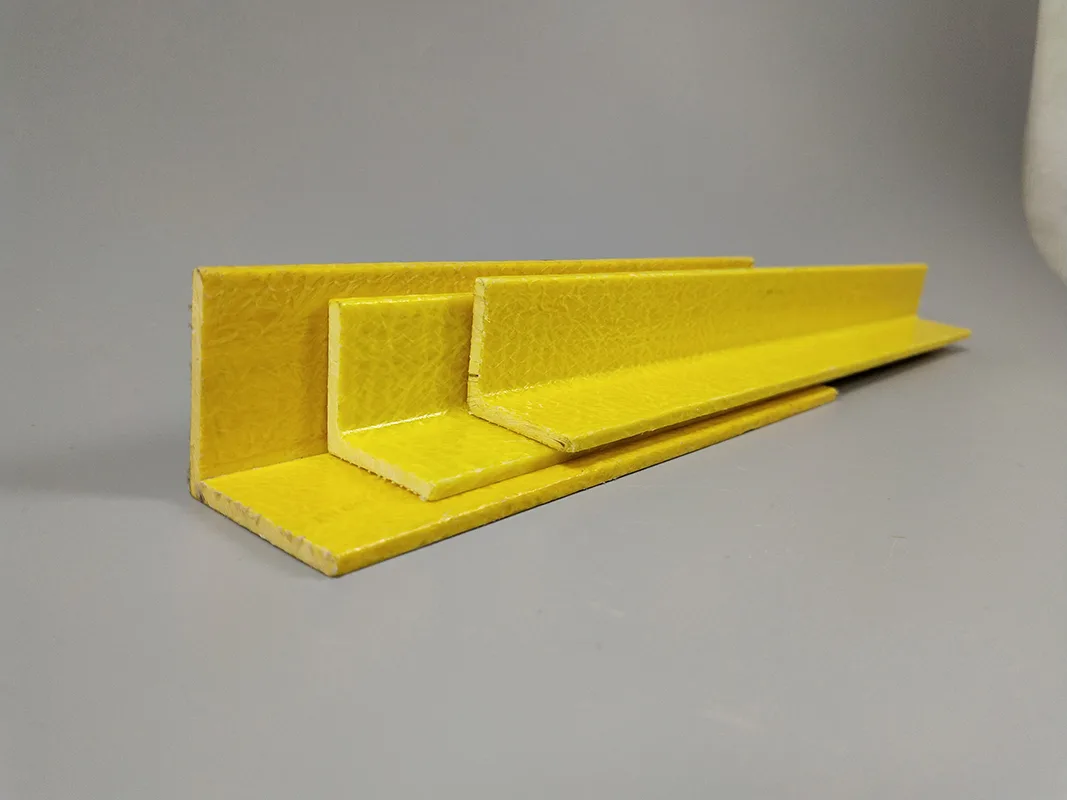

frp leg angles

What are FRP Leg Angles?

FRP, or Fiberglass Reinforced Plastic, is a composite material made of a polymer matrix reinforced with fibers, typically glass fibers. FRP leg angles are structural components shaped in an “L” form, widely used for their superior properties compared to traditional materials like steel or aluminum. They are lightweight, durable, and highly resistant to corrosion, making them an ideal choice for environments exposed to moisture, chemicals, or other corrosive elements.

Compared to traditional materials, FRP leg angles offer a unique combination of strength and flexibility. They do not rust or corrode, which significantly reduces maintenance costs over their lifetime. Furthermore, their non-conductive nature provides electrical insulation, a critical factor in specific industrial applications.

Benefits of Using FRP Leg Angles

- Corrosion Resistance

One of the most notable benefits of FRP leg angles is their resistance to corrosion. Unlike metal counterparts that rust or degrade when exposed to moisture or chemicals, FRP materials remain unaffected. This quality makes them ideal for use in environments such as coastal areas, chemical plants, and wastewater treatment facilities. - Lightweight and High Strength

Despite being significantly lighter than metals like steel or aluminum, FRP leg angles do not compromise on strength. Their lightweight nature facilitates easier handling and installation, reducing labor costs and time. The high strength-to-weight ratio ensures that structures built with FRP are robust and long-lasting. - Durability and Longevity

FRP leg angles are known for their durability. They can withstand harsh weather conditions, UV exposure, and mechanical wear without losing their integrity. This longevity makes them a cost-effective choice for long-term projects. - Electrical Insulation Properties

Another advantage of FRP leg angles is their non-conductive nature, providing excellent electrical insulation. This feature is particularly beneficial in applications where electrical safety is a concern, such as in power plants and electrical substations. - Cost-Effectiveness Over Time

Although the initial cost of FRP leg angles might be higher than some traditional materials, their low maintenance requirements and long lifespan result in significant cost savings over time. Reduced repair and replacement costs, combined with the benefits of reduced downtime, make FRP a cost-effective solution for many industries.

Applications of FRP Leg Angles

- Construction and Infrastructure

FRP leg angles are commonly used in construction for frameworks, platforms, walkways, and stair treads. Their lightweight and high-strength properties make them ideal for projects where weight is a critical factor, such as in bridge construction or elevated structures. - Marine and Offshore Industries

In marine environments, where corrosion is a significant concern, FRP leg angles are used for boat docks, railings, and ladders. Their resistance to saltwater corrosion extends their lifespan, reducing maintenance efforts and costs. - Electrical and Chemical Industries

The non-conductive and chemical-resistant properties of FRP make it a preferred choice in electrical and chemical plants. FRP leg angles are often used for cable trays, supports, and enclosures, providing both structural support and safety in these sensitive environments. - Transportation and Automotive Sectors

In the transportation industry, FRP leg angles are utilized for their lightweight nature, which contributes to fuel efficiency in vehicles. They are also used in railway construction, offering a durable and low-maintenance alternative to traditional materials.

Key Considerations When Choosing FRP Leg Angles

When selecting FRP leg angles for a project, several factors should be taken into account:

- Load-Bearing Capacity: Ensure that the chosen FRP leg angle can support the required load without compromising safety or performance.

- Environmental Factors: Consider the environmental conditions where the FRP will be used, such as exposure to UV rays, chemicals, or moisture.

- Installation Methods: FRP leg angles should be easy to install and fit seamlessly into the existing structure or framework.

- Compliance with Standards: Make sure that the FRP products comply with relevant industry standards and regulations, ensuring quality and safety.

Conclusion

FRP leg angles offer a versatile, durable, and cost-effective solution for a wide range of industrial applications. From construction to marine and electrical industries, their benefits are clear—corrosion resistance, lightweight, high strength, and longevity. When choosing FRP leg angles, consider factors like load capacity, environmental conditions, and compliance with industry standards to make the most informed decision.

If you’re looking to enhance your next project with durable, high-performance materials, consider the advantages of FRP leg angles. Invest in quality and longevity today!