Introduction

In the ever-evolving world of construction, the choice of materials plays a critical role in determining the longevity and efficiency of a project. Among the innovative solutions gaining traction today are FRP (Fiberglass Reinforced Plastic) embed angles. These components are not only transforming how structures are built but also offering a host of benefits that traditional materials like steel cannot match. From their superior corrosion resistance to their lightweight properties, FRP embed angles are becoming an essential part of modern construction projects. In this article, we’ll delve into what FRP embed angles are, explore their benefits and applications, and provide some practical installation tips to help you make the most of this advanced material.

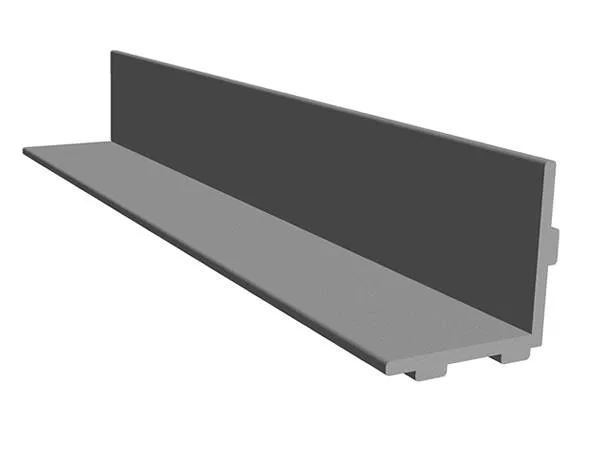

frp embed angles

What are FRP Embed Angles?

FRP embed angles are structural components made from Fiberglass Reinforced Plastic, designed to provide support and stability in various construction projects. Unlike traditional steel embed angles, FRP components offer a unique blend of strength and flexibility. The use of fiberglass gives these angles the ability to withstand environmental factors that typically lead to corrosion and degradation in metals. This makes them particularly useful in applications where exposure to moisture, chemicals, or extreme temperatures is a concern.

Benefits of Using FRP Embed Angles

One of the standout features of FRP embed angles is their exceptional corrosion resistance. Unlike steel, which can rust and weaken over time, FRP is impervious to moisture and most chemicals, making it an ideal choice for environments where corrosion is a significant concern. Additionally, FRP embed angles are significantly lighter than their steel counterparts. This reduced weight not only simplifies the installation process but also reduces the overall load on the structure, which can lead to cost savings in both materials and labor. Furthermore, FRP requires little to no maintenance, ensuring that the longevity of the structure is not compromised over time.

Applications of FRP Embed Angles in Construction

FRP embed angles are used in a variety of construction projects, particularly those that require materials to withstand harsh environmental conditions. For instance, in coastal or industrial areas where structures are regularly exposed to saltwater or chemical spills, FRP angles provide a durable solution that prevents the kind of corrosion that would quickly degrade steel. Industries such as marine construction, wastewater treatment plants, and chemical processing facilities are increasingly adopting FRP components to ensure the long-term durability of their infrastructure.

FRP vs. Steel Embed Angles

When comparing FRP and steel embed angles, several key differences emerge. While steel has been the traditional choice for many years, the advantages of FRP are becoming harder to ignore. FRP angles do not corrode, are lighter, and often easier to install. On the other hand, steel is known for its exceptional strength and load-bearing capacity. However, the maintenance costs and potential for rust in harsh environments make FRP a more cost-effective choice in the long run. Additionally, FRP can be molded into various shapes and sizes, providing greater flexibility for custom projects.

Installation Tips for FRP Embed Angles

Installing FRP embed angles is a straightforward process, but there are a few tips to ensure a successful installation. First, it’s important to use tools specifically designed for cutting and drilling FRP to avoid damaging the material. Second, always check the alignment and fit of the angles before securing them in place to ensure they provide the necessary support. Lastly, avoid over-tightening bolts, as FRP can crack under excessive pressure. With proper installation, FRP embed angles can offer years of reliable performance with minimal upkeep.

Conclusion

FRP embed angles represent a significant advancement in construction materials, offering a combination of durability, corrosion resistance, and ease of installation that traditional materials like steel cannot match. Whether you’re working on a project in a corrosive environment or simply looking for a lightweight, low-maintenance alternative to metal, FRP is a solution worth considering. As more industries recognize the benefits of FRP embed angles, their use is likely to become even more widespread. If you’re considering this material for your next project, consult with experts to explore how FRP can be integrated into your design for maximum benefit.