When working with fiberglass grating, one of the essential tools you’ll encounter is the span table. These tables are critical for ensuring the safety, durability, and performance of your grating installations. But what exactly are span tables, and how do you use them? Let’s break it down.

fiberglass grating span tables

What Are Fiberglass Grating Span Tables?

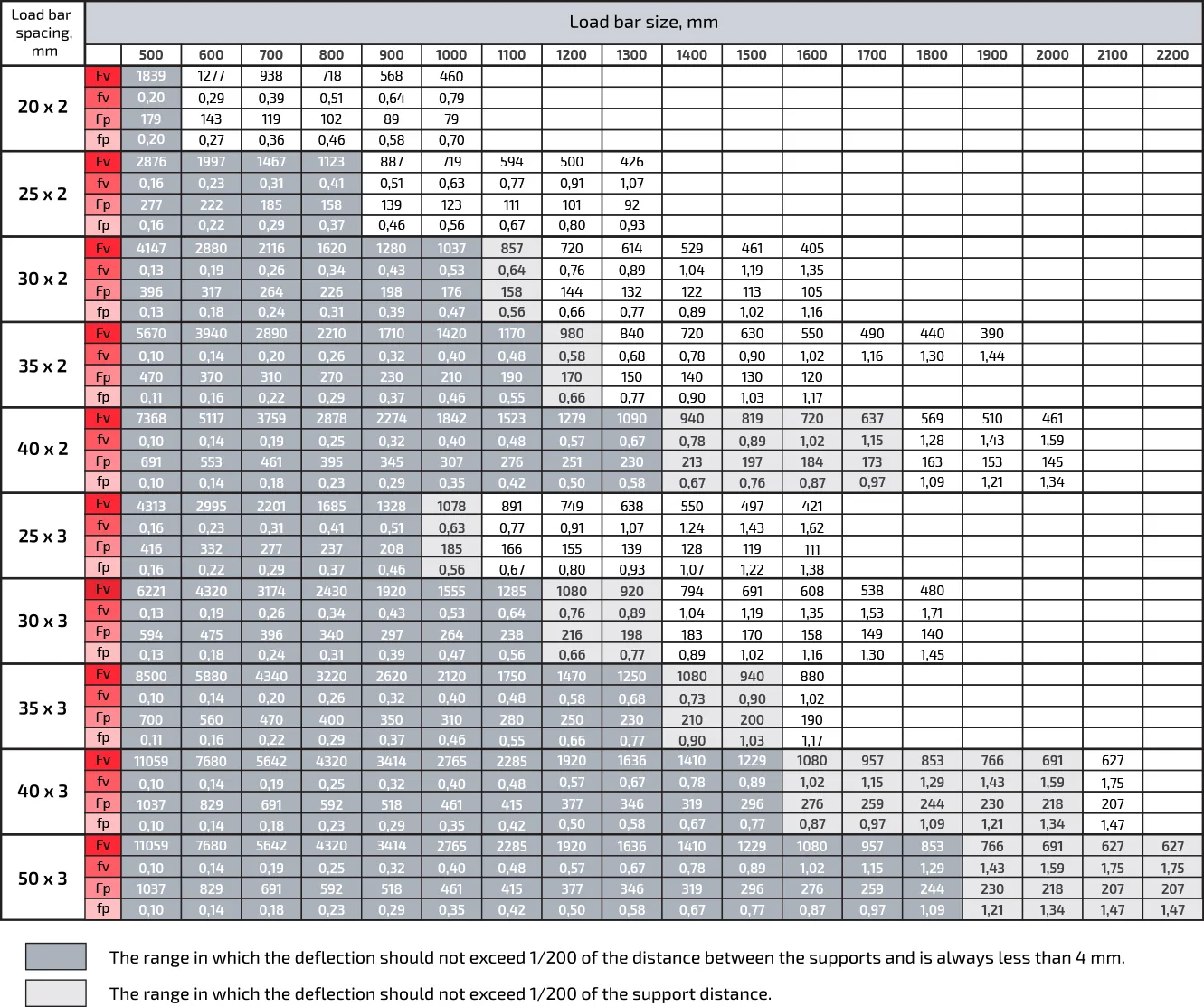

Fiberglass grating span tables provide guidelines on how much load a particular grating can support over a given distance. They help you determine the maximum distance (span) that the grating can cover between supports without compromising structural integrity.

Why Are Span Tables Important?

- Safety: Using span tables ensures that the grating can handle the expected load without failing, preventing accidents and injuries.

- Durability: Proper span lengths prevent excessive deflection (bending) and extend the life of the grating.

- Compliance: Many industries have regulations requiring adherence to span table recommendations to ensure safe working conditions.

How to Read Span Tables

- Load Type: Span tables often differentiate between uniform loads (spread evenly across the grating) and concentrated loads (focused on a specific area).

- Span Length: This is the distance between the supports of the grating.

- Deflection: This indicates how much the grating will bend under a given load. Acceptable deflection limits are usually specified to ensure structural stability and safety.

- Grating Size and Thickness: The tables will list different grating sizes and thicknesses, showing how they perform under various loads and spans.

Example of Using a Span Table

Let’s say you need to install fiberglass grating in an industrial setting where it will support heavy machinery. You check the span table and find the following data for a specific grating type:

- Span Length: 2 feet

- Uniform Load Capacity: 300 pounds per square foot

- Concentrated Load Capacity: 1000 pounds on a 4-inch by 4-inch area

- Maximum Deflection: 0.25 inches

Based on this table, you can safely install the grating with supports 2 feet apart, knowing it will handle the expected loads without excessive deflection.

Tips for Using Span Tables

- Know Your Loads: Accurately estimate the loads the grating will support, including both uniform and concentrated loads.

- Choose the Right Grating: Different gratings have varying capacities. Ensure you select one that meets your load requirements.

- Consider Environmental Factors: Temperature, chemicals, and other environmental factors can affect grating performance. Make sure the chosen grating is suitable for your specific conditions.

- Regular Inspections: Even with proper installation, regular inspections are necessary to ensure the grating remains in good condition.

Conclusion

Fiberglass grating span tables are essential tools for anyone involved in the installation and maintenance of these materials. They provide crucial information to ensure safety, durability, and compliance with industry standards. By understanding and using these tables correctly, you can make informed decisions that protect both people and property.