Introduction

Pultruded fiberglass round tubes have revolutionized the industrial materials landscape. Known for their exceptional strength, durability, and lightweight properties, these tubes are quickly becoming the preferred choice across various sectors. Whether in construction, marine, or electrical applications, their versatility and high performance make them an ideal alternative to traditional materials like steel and aluminum. In this article, we’ll explore the top benefits of high-strength pultruded fiberglass round tubes and why they’re a game-changer for industrial applications.

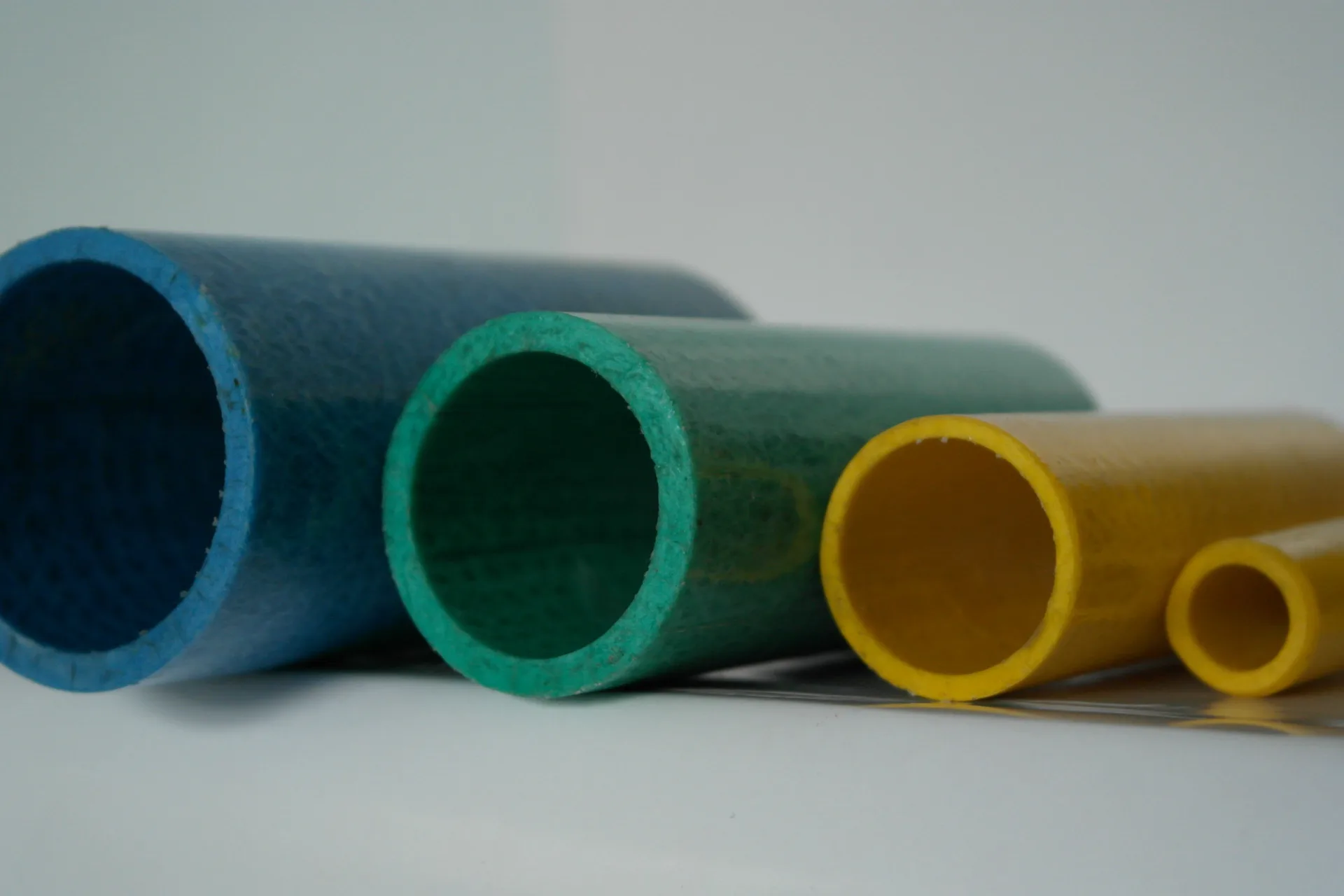

high strength pultruded fiberglass round tube

What Are Pultruded Fiberglass Round Tubes?

Definition and Manufacturing Process

Pultruded fiberglass round tubes are made using a specialized manufacturing process called pultrusion. This process involves pulling reinforced fiberglass strands through a resin bath and then shaping them through a heated die. The result is a tube with a consistent cross-section, high strength, and uniform quality.

Key Features of Pultruded Fiberglass Round Tubes

- Lightweight Structure: Despite their strength, these tubes are significantly lighter than metals, making them easier to handle and transport.

- High Tensile Strength: Pultruded fiberglass tubes offer remarkable strength-to-weight ratios, often outperforming traditional materials like steel.

- Corrosion Resistance: They resist damage from chemicals, moisture, and UV rays, ensuring longevity in harsh environments.

Top Benefits of High Strength Pultruded Fiberglass Round Tubes

Superior Strength-to-Weight Ratio

Compared to steel or aluminum, pultruded fiberglass round tubes provide unparalleled strength while remaining lightweight. This combination makes them an excellent choice for projects where weight reduction is crucial, such as aerospace or automotive applications.

Corrosion Resistance for Harsh Environments

In industries like marine and chemical processing, exposure to corrosive substances is a constant challenge. Pultruded fiberglass tubes resist rust, rot, and chemical degradation, ensuring a longer lifespan and reduced maintenance costs.

Electrical and Thermal Insulation

Pultruded fiberglass round tubes are non-conductive, making them safe for electrical applications. Additionally, their thermal insulation properties are ideal for environments where temperature regulation is critical.

Cost Efficiency and Long Lifespan

While the initial investment might be higher than traditional materials, the durability and low maintenance requirements of pultruded fiberglass round tubes result in significant cost savings over time. Their extended lifespan makes them a cost-effective solution for industrial projects.

Key Industrial Applications

Construction and Infrastructure

Pultruded fiberglass round tubes are widely used in construction for railings, bridges, and structural supports. Their lightweight nature simplifies installation, while their strength ensures reliability.

Electrical and Telecommunications

In the electrical sector, these tubes serve as conduits and supports for cables. Their non-conductive properties add an extra layer of safety in high-voltage environments.

Marine and Chemical Industries

From pipelines and docks to storage tanks, pultruded fiberglass tubes excel in environments exposed to saltwater or harsh chemicals, where traditional materials often fail.

Why Choose Pultruded Fiberglass Round Tubes Over Alternatives?

Comparison with Traditional Materials

Steel, wood, and aluminum have been standard materials for decades, but each comes with limitations. Steel is heavy and prone to rust, wood can rot and warp, and aluminum may not withstand highly corrosive conditions. Pultruded fiberglass round tubes offer a superior alternative by addressing these weaknesses.

Environmental Benefits

As sustainability becomes a priority, pultruded fiberglass round tubes stand out for their recyclability and lower carbon footprint during manufacturing and transport.

Conclusion

Pultruded fiberglass round tubes combine strength, durability, and versatility, making them indispensable in modern industrial applications. Their ability to withstand harsh conditions, coupled with their cost-efficiency and environmental benefits, sets them apart from traditional materials. Whether you’re working on a construction project or looking for solutions in the marine or electrical sectors, these tubes are worth considering.

Call-to-Action

Explore the endless possibilities of high-strength pultruded fiberglass round tubes for your next project. Contact our experts today to find the perfect solution tailored to your needs!