Introduction

Molded fiberglass grating is quickly becoming a go-to solution for industries that demand durability, safety, and efficiency. Its lightweight yet robust construction, combined with resistance to harsh environments, makes it an excellent alternative to traditional materials like steel and aluminum. In this article, we’ll explore the top five advantages of molded fiberglass grating and why it’s an ideal choice for a wide range of applications.

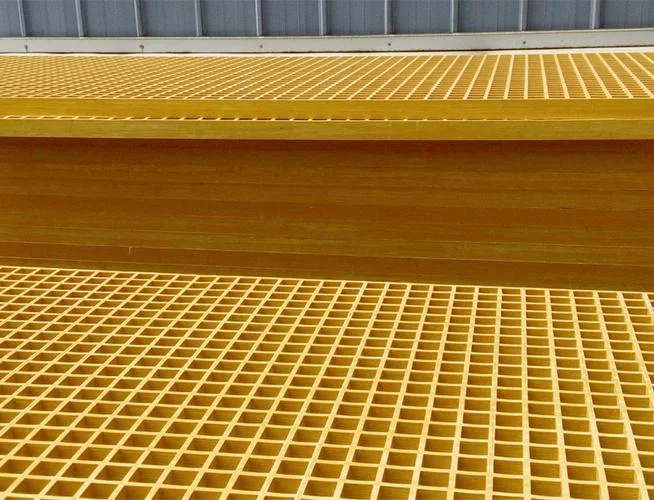

molded fiberglass grating

What is Molded Fiberglass Grating?

Molded fiberglass grating is a composite material created by combining resin and continuous fiberglass strands in a molded process. This unique construction results in a grid-like structure that is both lightweight and highly durable. Widely used in industries such as marine, oil and gas, and wastewater treatment, molded fiberglass grating is prized for its ability to withstand extreme conditions while maintaining functionality.

Top 5 Advantages of Molded Fiberglass Grating

1. Corrosion Resistance

One of the standout features of molded fiberglass grating is its exceptional resistance to corrosion. Unlike metal gratings that can rust or deteriorate when exposed to moisture, chemicals, or saltwater, molded fiberglass grating maintains its structural integrity in the harshest environments. This makes it ideal for industries like marine operations, chemical plants, and wastewater treatment facilities, where exposure to corrosive elements is inevitable.

2. High Strength-to-Weight Ratio

Molded fiberglass grating offers a remarkable balance of strength and weight. It is significantly lighter than traditional materials such as steel, yet it can handle comparable load capacities. This lightweight nature simplifies handling and installation, reducing labor costs and project timelines. Additionally, its strength ensures long-term performance, even under heavy use.

3. Non-Conductive and Safe

Safety is a top priority in industrial settings, and molded fiberglass grating excels in this regard. Its non-conductive properties make it an excellent choice for environments where electrical hazards are a concern, such as power plants and electrical substations. Additionally, fire-retardant options enhance safety, making it a trusted material in high-risk areas.

4. Low Maintenance

Molded fiberglass grating requires minimal upkeep, making it a cost-effective solution over its lifespan. Unlike metal gratings, which may need regular painting, coatings, or replacements due to rust, fiberglass grating resists wear and tear. This results in fewer maintenance disruptions and reduced long-term costs.

5. Easy Installation

Thanks to its lightweight composition, molded fiberglass grating is easy to transport, cut, and install. This ease of handling reduces labor hours and equipment needs, offering significant cost savings. Moreover, its versatility allows it to be tailored to fit specific project requirements, ensuring a seamless installation process.

Common Applications of Molded Fiberglass Grating

Molded fiberglass grating is used across a wide array of industries due to its versatility and durability. Key applications include:

- Marine Environments: Ideal for docks, platforms, and gangways due to its corrosion resistance.

- Chemical Processing Plants: Withstands exposure to aggressive chemicals and extreme temperatures.

- Wastewater Treatment Facilities: Handles constant moisture and harsh cleaning agents without compromising performance.

- Electrical and Power Plants: Provides safe, non-conductive flooring and walkways.

These examples highlight its adaptability and effectiveness in demanding settings.

How to Choose the Right Molded Fiberglass Grating

When selecting molded fiberglass grating for your project, consider the following factors:

- Load Requirements: Assess the weight and pressure the grating must support.

- Environmental Conditions: Choose the right resin type to match exposure to chemicals, moisture, or UV rays.

- Application Needs: Consider factors like slip resistance, fire retardance, and ease of installation for your specific use case.

Consulting with a supplier or expert can help you determine the best option for your needs.

Conclusion

Molded fiberglass grating is a modern solution that combines durability, safety, and ease of use, making it an invaluable material for various industrial applications. Its resistance to corrosion, lightweight yet strong structure, and low-maintenance properties make it a superior choice over traditional materials.

Ready to explore the benefits for your next project? Reach out to a molded fiberglass grating specialist today to find the perfect fit for your requirements!