Introduction:

Ortho molded fiberglass grating is a versatile and durable material that has become increasingly popular in various industries due to its superior strength, corrosion resistance, and lightweight properties. Whether you’re in construction, manufacturing, or marine industries, understanding the benefits and applications of ortho molded fiberglass grating can help you make informed decisions. In this comprehensive guide, we’ll explore what ortho molded fiberglass grating is, its key benefits, common applications, and how to choose the right type for your needs.

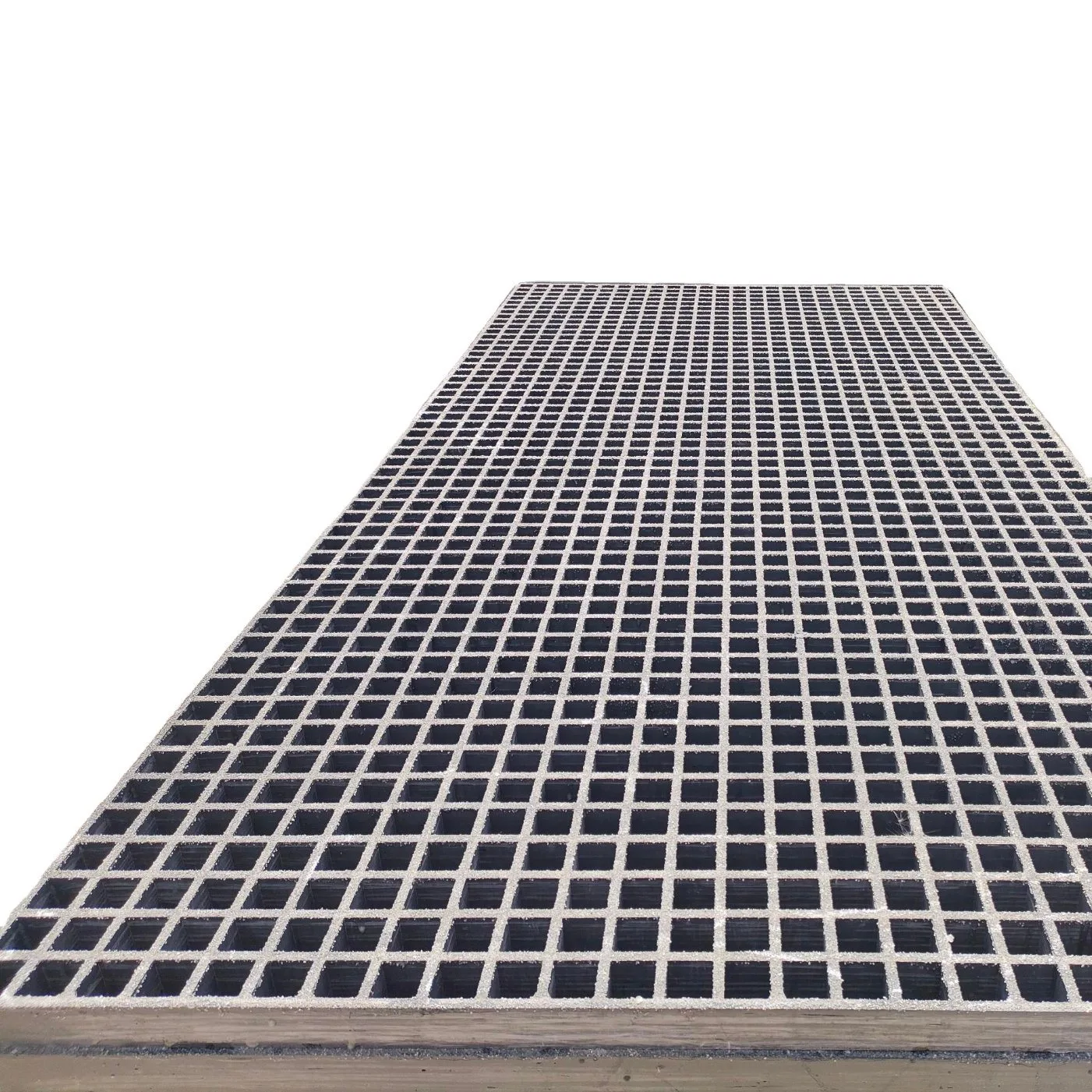

ortho molded fiberglass grating

What is Ortho Molded Fiberglass Grating?

Ortho molded fiberglass grating is a type of fiberglass-reinforced plastic (FRP) grating that is made by molding continuous fiberglass strands with an ortho-phthalic polyester resin. This combination creates a high-strength, lightweight, and corrosion-resistant material that is ideal for environments where traditional materials like steel or wood would degrade quickly.

Key Characteristics:

- Durability: Ortho molded fiberglass grating offers excellent durability, particularly in corrosive environments.

- Non-Conductive: It is non-conductive, making it safe for use in electrical applications.

- Slip Resistance: The grating’s surface can be molded with anti-slip textures, providing additional safety in wet or oily conditions.

- Fire Retardant: Many types of ortho molded fiberglass grating are formulated to be fire retardant, adding another layer of safety.

Benefits of Ortho Molded Fiberglass Grating

- Corrosion Resistance: One of the most significant advantages of ortho molded fiberglass grating is its exceptional resistance to corrosion. Unlike steel, which rusts, or wood, which rots, fiberglass grating withstands exposure to moisture, chemicals, and saltwater. This makes it an ideal choice for environments such as chemical plants, marine docks, and wastewater treatment facilities.

- High Strength-to-Weight Ratio: Despite its lightweight nature, ortho molded fiberglass grating offers a high strength-to-weight ratio. It provides the necessary load-bearing capacity without the added weight, which simplifies installation and reduces transportation costs.

- Cost-Effectiveness: While the initial cost of ortho molded fiberglass grating may be higher than traditional materials, its long-term cost benefits are substantial. Its durability and low maintenance requirements lead to lower replacement costs, reduced downtime, and less frequent repairs.

- Safety Features: Ortho molded fiberglass grating is non-conductive and slip-resistant, making it a safer option for use in environments where electrical hazards or slippery conditions are a concern. Additionally, its fire-retardant properties further enhance workplace safety.

Common Applications of Ortho Molded Fiberglass Grating

- Industrial Settings: In industries such as petrochemical, food processing, and manufacturing, ortho molded fiberglass grating is used for flooring, walkways, and platforms. Its corrosion resistance and low maintenance requirements make it suitable for environments exposed to chemicals, oils, and other corrosive substances.

- Marine Environments: Due to its resistance to saltwater and moisture, ortho molded fiberglass grating is commonly used in marine applications such as docks, ship decks, and offshore platforms. Its non-slip surface ensures safety for workers and equipment.

- Water Treatment Plants: In water and wastewater treatment facilities, ortho molded fiberglass grating is used for walkways, grating covers, and drainage systems. Its resistance to corrosion and chemical exposure ensures a long service life in these demanding environments.

- Recreational Facilities: Ortho molded fiberglass grating is also used in recreational settings like pools, water parks, and amusement parks. Its slip-resistant properties and resistance to chlorine and other pool chemicals make it a safe and durable choice for wet areas.

How to Choose the Right Ortho Molded Fiberglass Grating

- Consider Load Requirements: Understand the load requirements for your specific application. Different types of fiberglass gratings are designed to support varying levels of weight, so selecting a grating that meets or exceeds your load requirements is essential.

- Evaluate the Environment: Consider the environmental conditions where the grating will be installed. For corrosive or high-moisture environments, ensure that the selected grating is formulated to resist the specific conditions it will face.

- Choose the Right Size and Type: Ortho molded fiberglass gratings come in various sizes and types, including standard, mini-mesh, and covered grating. Choose the one that best fits your application’s needs.

- Maintenance and Care: While fiberglass gratings require less maintenance than metal or wood, regular inspections and cleaning will help extend their lifespan and maintain their appearance. Remove any debris or chemical buildup that could affect the grating’s performance.

Conclusion

Ortho molded fiberglass grating offers numerous benefits, including corrosion resistance, high strength-to-weight ratio, and enhanced safety features, making it an excellent choice for a wide range of applications. Whether you’re looking to upgrade an industrial facility, marine deck, or recreational area, choosing the right type of ortho molded fiberglass grating can provide long-lasting performance and safety. Explore our collection of ortho molded fiberglass gratings today and find the perfect fit for your needs.