Introduction

Fiber Reinforced Polymer (FRP) equal angles are rapidly becoming the go-to material for various construction and engineering applications. Known for their strength, durability, and corrosion resistance, FRP equal angles offer numerous advantages over traditional materials like steel or aluminum. This guide will explore everything you need to know about FRP equal angles, including their benefits, applications, and installation tips, to help you make an informed decision for your next project.

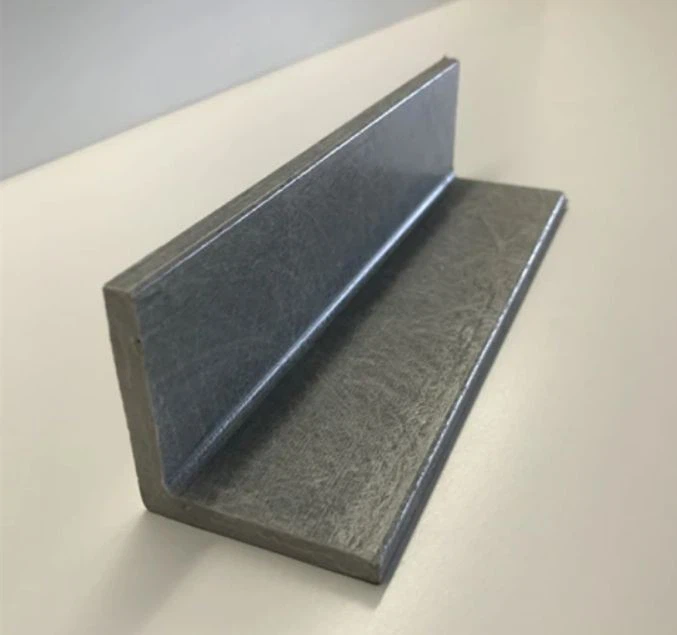

frp equal angle

What is FRP Equal Angle?

FRP equal angles are structural components made from Fiber Reinforced Polymer (FRP), a composite material consisting of a polymer matrix reinforced with fibers. These fibers, usually made from glass, carbon, or aramid, provide high tensile strength and stiffness to the composite, while the polymer matrix offers resistance to environmental factors such as moisture and chemicals.

Compared to traditional materials like steel or aluminum, FRP equal angles stand out due to their lightweight nature, ease of installation, and superior resistance to corrosion and chemical exposure. They are particularly suitable for environments where metal components would quickly degrade or require frequent maintenance.

Key Benefits of Using FRP Equal Angles

- Durability and Corrosion Resistance

One of the primary reasons for the growing popularity of FRP equal angles is their exceptional durability. Unlike steel, FRP does not rust or corrode when exposed to moisture or harsh chemicals. This makes it ideal for use in environments where metal components are prone to corrosion, such as in marine or coastal areas. - Lightweight and Easy to Handle

FRP equal angles are significantly lighter than their metal counterparts, which makes them easier to transport and install. This weight advantage reduces transportation costs and minimizes the need for heavy lifting equipment during installation, ultimately saving time and money on projects. - Low Maintenance Requirements

FRP materials require little to no maintenance due to their resistance to environmental degradation. This makes them a cost-effective choice in the long run, as they do not need regular painting, coating, or treatment to maintain their structural integrity and appearance. - High Strength-to-Weight Ratio

Despite being lightweight, FRP equal angles offer an excellent strength-to-weight ratio, making them suitable for applications where strong and lightweight materials are necessary. They can withstand heavy loads and provide stability in structures without adding significant weight, reducing the overall structural load.

Common Applications of FRP Equal Angles

FRP equal angles are versatile components used in a wide range of applications:

- Industrial and Commercial Uses: FRP equal angles are commonly used in industrial settings for constructing platforms, stairways, walkways, and handrails. Their resistance to corrosion and chemicals makes them ideal for chemical plants, refineries, and wastewater treatment facilities.

- Marine and Offshore Applications: Due to their excellent resistance to saltwater and moisture, FRP equal angles are widely used in the marine industry for building docks, boat lifts, and other structures that come into direct contact with water.

- Infrastructure Projects: In civil engineering, FRP equal angles are used for reinforcing structures such as bridges, tunnels, and retaining walls. Their lightweight nature allows for easier transportation and installation in challenging terrains.

How to Install FRP Equal Angles

Installing FRP equal angles is relatively straightforward, but it requires careful planning and the right tools. Here is a step-by-step guide to ensure a smooth installation process:

- Prepare the Surface: Before installation, ensure the surface is clean, dry, and free from any debris or contaminants that could interfere with bonding or fastening.

- Measure and Cut: Use a tape measure to determine the length of FRP equal angles needed for the project. Cut the angles using a saw equipped with a diamond or carbide-tipped blade to prevent splintering.

- Position the Angles: Place the FRP equal angles in the desired position, ensuring they are aligned correctly. Use clamps to hold them in place while you secure them.

- Drill Holes and Secure: Drill holes through the FRP equal angles and into the substrate using a drill fitted with a carbide-tipped bit. Secure the angles with corrosion-resistant bolts or fasteners suitable for FRP materials.

- Check Alignment and Stability: After securing, check the alignment and stability of the installed angles. Make any necessary adjustments before proceeding to the next steps in your project.

- Final Inspection: Perform a final inspection to ensure all angles are correctly installed, secure, and aligned. Make sure that no sharp edges are exposed, and all fasteners are tight.

Conclusion

FRP equal angles are a versatile and durable alternative to traditional materials, offering a range of benefits such as corrosion resistance, lightweight construction, and low maintenance. Whether you’re working on an industrial, marine, or infrastructure project, FRP equal angles can provide the strength and reliability needed for your application. Consider using FRP equal angles in your next project to enjoy their many advantages and ensure long-lasting performance.