Introduction

Fiberglass grating systems are a popular choice for various industries due to their strength, durability, and resistance to corrosion. These grating systems are often used in environments where metal grating would succumb to rust or require frequent maintenance. However, the effectiveness and longevity of fiberglass grating rely heavily on one often-overlooked component: the fasteners.

Fiberglass grating fasteners are essential for securing the grating panels to the underlying support structure. Without the proper fasteners, the system could fail, leading to potential safety hazards, increased wear and tear, and diminished performance. In this guide, we will explore the different types of fiberglass grating fasteners, their uses, and the benefits of selecting the right ones for your project.

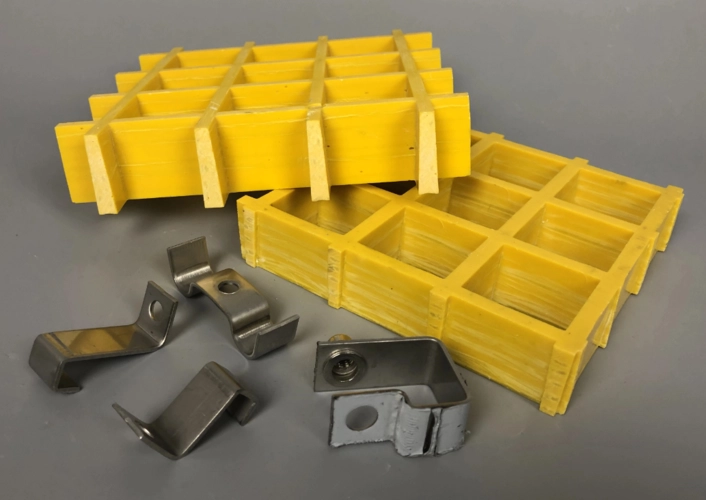

fiberglass grating fasteners

What Are Fiberglass Grating Fasteners?

Fiberglass grating fasteners are specialized components used to secure fiberglass grating panels to their support structure. These fasteners ensure that the grating stays in place, even under heavy loads or in harsh conditions. While fiberglass grating is known for its corrosion resistance and durability, it is the proper selection of fasteners that guarantees the system’s overall stability.

The fasteners are usually made from materials such as stainless steel or other corrosion-resistant alloys to complement the fiberglass grating’s durability. They come in a variety of shapes and designs, each suited to different applications, depending on the project’s specific needs.

Types of Fiberglass Grating Fasteners

Choosing the right type of fiberglass grating fasteners is critical to ensuring a secure installation. There are several types of fasteners available, each designed for specific applications:

- M-Clips: M-Clips are designed to secure grating panels to their supports, providing a solid and reliable attachment. They are often used in standard applications where there is minimal risk of environmental exposure.

- C-Clips: These clips are commonly used when securing grating panels edge-to-edge. They help ensure that the grating remains connected without leaving any gaps, which is crucial in safety-conscious industries.

- G-Clips: Known for their ease of installation, G-Clips are typically used in applications where the grating is already installed but needs additional fastening. They require no drilling, making them ideal for retrofitting or quick repairs.

- Saddle Clips: Saddle clips wrap around the top bar of the fiberglass grating and are bolted into the supporting structure. These clips offer robust fastening and are often used in environments with heavy foot traffic or equipment loads.

Each of these fastener types has its own set of benefits, and selecting the correct one will depend on the specific requirements of the project, including the load-bearing capacity, environmental exposure, and ease of installation.

Uses of Fiberglass Grating Fasteners in Various Industries

Fiberglass grating fasteners are used across numerous industries due to their versatility and strength. Below are some key industries that rely heavily on fiberglass grating systems and their fasteners:

- Industrial Flooring: Fiberglass grating is a popular choice for industrial flooring due to its non-slip surface and resistance to chemicals. Fasteners play a critical role in ensuring the grating stays securely in place in high-traffic areas.

- Marine and Offshore Platforms: In marine environments, exposure to saltwater can quickly corrode traditional metal grating systems. Fiberglass grating, secured with corrosion-resistant fasteners, is ideal for these harsh conditions.

- Chemical Plants: Chemical plants often require materials that can withstand exposure to corrosive substances. Fiberglass grating fasteners ensure the grating system remains stable while resisting chemical degradation.

- Water Treatment Facilities: Water treatment plants deal with constant moisture, making fiberglass grating an excellent choice for flooring, walkways, and platforms. The fasteners used in these settings must also resist corrosion to maintain system integrity.

In each of these industries, fiberglass grating fasteners are crucial to maintaining both safety and operational efficiency.

Benefits of Choosing the Right Fiberglass Grating Fasteners

Selecting the correct fiberglass grating fasteners for your project offers several key benefits:

- Durability and Long-Term Performance: The right fasteners ensure that your grating system stays securely in place over time, even in high-traffic or high-load environments. This longevity reduces maintenance costs and the need for frequent replacements.

- Enhanced Safety and Stability: Fasteners provide the necessary support to keep grating panels from shifting or moving, reducing the risk of accidents or injuries due to loose or unstable flooring.

- Corrosion Resistance: Many fiberglass grating fasteners are made from corrosion-resistant materials, ensuring that the grating remains secure even in the presence of moisture, chemicals, or saltwater. This is essential in industries such as marine, chemical, and wastewater treatment, where environmental exposure is a constant concern.

By choosing the correct fasteners, you can improve the overall performance and lifespan of your fiberglass grating system, ensuring it remains safe and functional in even the harshest environments.

How to Choose the Right Fiberglass Grating Fasteners for Your Project

When selecting fiberglass grating fasteners, several factors should be considered to ensure you get the best results for your specific application:

- Load Requirements: Assess the weight that the grating needs to support. Heavier loads will require more durable fasteners designed for high-stress environments.

- Environmental Conditions: If the grating system will be exposed to harsh environmental conditions such as chemicals, moisture, or extreme temperatures, choose fasteners made from corrosion-resistant materials.

- Grating Compatibility: Make sure that the fasteners are compatible with the type of fiberglass grating you are using. Different types of grating may require specific fasteners for proper installation and security.

- Ease of Installation: Depending on whether the installation is new or a retrofit, the ease of installing the fasteners might be an important consideration. G-Clips, for example, are excellent for retrofits because they do not require drilling.

By taking these factors into account, you can ensure that your fiberglass grating system is securely fastened and capable of withstanding the demands of your specific application.

Conclusion

Fiberglass grating fasteners are an essential component of any fiberglass grating system, playing a critical role in ensuring stability, safety, and long-term performance. By choosing the right type of fasteners, you can enhance the durability and safety of your grating system, ensuring that it performs well even in the most demanding environments.

Whether you’re installing grating for industrial flooring, marine platforms, or chemical plants, the proper fasteners will provide the support and security necessary to keep the grating system in place. Always consider load requirements, environmental exposure, and grating compatibility when selecting your fasteners.

For expert advice or assistance in choosing the right fasteners for your fiberglass grating system, consult with a supplier or industry professional to ensure you make the best decision for your project.