Introduction

When it comes to industrial applications that demand reliability and safety, the choice of materials is crucial. Phenolic GRP (Glass Reinforced Plastic) grating has become a go-to solution for many industries due to its outstanding performance in harsh environments. This article delves into the many benefits of Phenolic GRP grating, focusing on its durability, non-slip properties, lightweight design, and long-term cost-effectiveness.

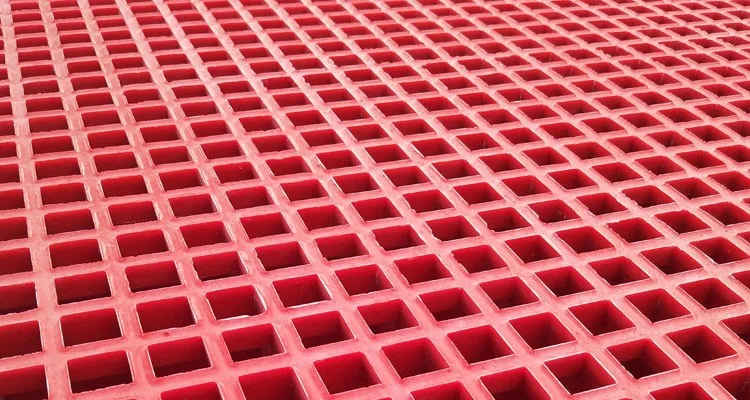

phenolic grp grating

What is Phenolic GRP Grating?

Phenolic GRP grating is a type of reinforced plastic material made from a combination of glass fibers and phenolic resin. The glass fibers provide strength and rigidity, while the phenolic resin ensures chemical resistance and flame retardancy. This unique combination makes Phenolic GRP grating an ideal choice for areas exposed to extreme conditions, including high temperatures and harsh chemicals.

Compared to other types of grating, such as those made from steel or fiberglass, Phenolic GRP offers distinct advantages, particularly in environments where corrosion, UV degradation, and heavy chemical exposure are concerns.

Key Benefits of Phenolic GRP Grating

Exceptional Durability in Harsh Environments

One of the standout features of Phenolic GRP grating is its exceptional durability. This material is designed to withstand the most aggressive conditions. Unlike metal gratings that can corrode or degrade when exposed to chemicals, Phenolic GRP grating resists a wide range of chemicals, including acids, alkalis, and salts. This makes it an ideal choice for industries like petrochemicals, pharmaceuticals, and food processing, where exposure to such elements is routine.

Phenolic GRP grating also excels in high-temperature environments, maintaining its strength and structure even when exposed to extreme heat. This performance is especially valuable in industrial plants, offshore platforms, and other demanding settings where metal or traditional materials would quickly fail.

Lightweight and Strong

Despite its robust performance, Phenolic GRP grating is remarkably lightweight, which makes it much easier to handle and install compared to metal grating. This characteristic reduces installation time and labor costs, as workers can move and position the grating with ease, even in remote or hard-to-reach areas.

But don’t let its lightness fool you – Phenolic GRP grating is strong and durable, able to support significant loads without bending or breaking. This strength-to-weight ratio makes it a highly effective alternative to heavy steel grating, offering a balance between structural integrity and ease of installation.

Non-Slip Surface for Enhanced Safety

In environments where safety is a top priority, the non-slip surface of Phenolic GRP grating is a major advantage. The grating’s textured surface ensures excellent traction, preventing slips and falls in wet, oily, or hazardous conditions.

This feature is particularly crucial in industrial settings like chemical plants, oil rigs, and wastewater treatment facilities, where workers are often exposed to slippery conditions. The non-slip surface of Phenolic GRP grating meets stringent safety standards, ensuring a safer work environment for employees.

Corrosion Resistance and Low Maintenance

Phenolic GRP grating stands out for its corrosion resistance. Unlike metal gratings that can rust and degrade over time, Phenolic GRP is impervious to the effects of rust, corrosion, and environmental wear. Its resistance to corrosion from saltwater, UV rays, and harsh chemicals means that it will maintain its integrity for many years without needing frequent replacements.

Additionally, this material requires minimal maintenance. In corrosive environments, traditional grating materials often need regular inspections and repairs, but Phenolic GRP grating’s resilience means that it remains in excellent condition with very little upkeep. This makes it a cost-effective solution over the long term, particularly for industries where maintenance costs can quickly add up.

Cost-Effectiveness Over Time

While the initial cost of Phenolic GRP grating may be higher than some other materials, its long-term cost-effectiveness makes it a smart investment. The durability and low-maintenance nature of Phenolic GRP grating mean that companies will spend less on replacements, repairs, and labor.

Over time, the savings on maintenance and downtime can far outweigh the initial installation costs. For industries where reliability and safety are paramount, the upfront investment in Phenolic GRP grating is well worth it.

Common Applications of Phenolic GRP Grating

Phenolic GRP grating is used in a wide range of industrial and commercial applications, especially where chemical resistance and safety are critical. Some of the most common uses include:

- Chemical Plants and Refineries: Due to its resistance to harsh chemicals, Phenolic GRP grating is widely used in environments where chemicals like acids, bases, and solvents are present.

- Offshore Platforms: The corrosion-resistant properties of Phenolic GRP make it an ideal choice for offshore oil and gas rigs, where the material is exposed to saltwater, high humidity, and UV radiation.

- Wastewater Treatment Plants: The non-slip and corrosion-resistant qualities of Phenolic GRP grating are perfect for the wet, harsh conditions found in wastewater treatment facilities.

- Food Processing and Pharmaceutical Industries: Phenolic GRP’s resistance to contamination and ease of cleaning make it suitable for environments where hygiene is a top concern.

Installation and Maintenance of Phenolic GRP Grating

Installing Phenolic GRP grating is relatively straightforward. The material is lightweight, which makes it easy to cut and fit into place. It is typically installed using stainless steel clips or fasteners to ensure a secure fit. For best results, it’s important to ensure that the grating is installed on a solid surface and checked regularly for wear.

When it comes to maintenance, Phenolic GRP grating requires minimal effort. Periodic cleaning with water and non-abrasive cleaners is usually enough to keep it in top condition. For environments where the grating is exposed to heavy chemical or mechanical wear, routine inspections can help catch any potential issues early.

Conclusion

Phenolic GRP grating offers a unique combination of durability, strength, and safety features that make it a top choice for industries dealing with harsh environments. Its resistance to chemicals, corrosion, and high temperatures, coupled with its non-slip surface and low-maintenance nature, ensure that it performs reliably for years.

By choosing Phenolic GRP grating for your next project, you are investing in a material that will not only save you time and money but also ensure the safety and efficiency of your operations. If you’re ready to explore how Phenolic GRP grating can benefit your facility, contact us today for more information or a consultation.