Introduction

When it comes to flooring solutions for industrial, commercial, and hazardous environments, Duragrid fiberglass grating has become a go-to option for businesses looking for durability, safety, and cost-effectiveness. Known for its resilience and non-corrosive properties, Duragrid fiberglass grating offers a multitude of benefits that make it a superior choice for demanding flooring applications.

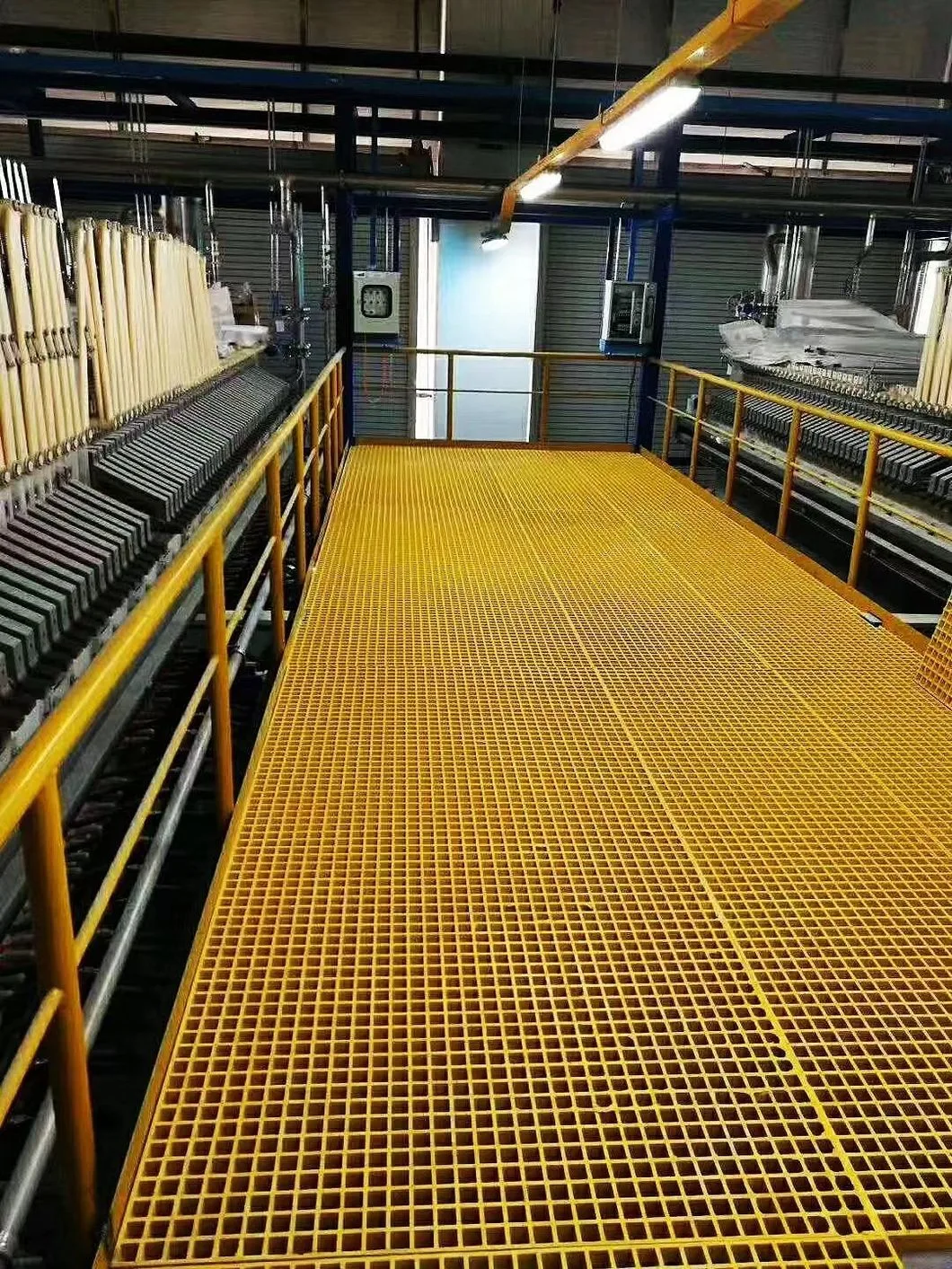

duragrid fiberglass grating

What is Duragrid Fiberglass Grating?

Composition and Manufacturing Process

Duragrid fiberglass grating is made from a combination of high-strength fiberglass and resin, which is molded into a grid pattern. This unique composition makes it significantly more lightweight and corrosion-resistant than traditional materials like steel or aluminum. During the manufacturing process, fiberglass strands are impregnated with resin, and the grating is carefully molded to ensure high strength and load-bearing capacity.

Key Features

Some of the standout features of Duragrid fiberglass grating include:

- Corrosion Resistance: Unlike metal grating, fiberglass does not rust or corrode when exposed to chemicals or moisture.

- Lightweight Construction: Duragrid is easier to handle and install compared to metal alternatives, making it a cost-effective choice.

- High Load-Bearing Capacity: Duragrid is designed to support heavy machinery, foot traffic, and industrial equipment without compromising its integrity.

Benefits of Duragrid Fiberglass Grating

Exceptional Durability in Harsh Environments

Duragrid fiberglass grating excels in environments where metals would fail. It can withstand exposure to harsh chemicals, acids, and extreme temperatures. Whether you’re working in a factory, offshore platform, or a food processing facility, Duragrid’s ability to resist corrosion, UV degradation, and wear ensures it remains functional over a long period.

Increased Safety for Workers

Worker safety is always a top priority in industrial environments, and Duragrid fiberglass grating contributes significantly to creating a safer workspace. Its slip-resistant surface provides excellent traction even in wet conditions, reducing the risk of slips and falls. Furthermore, it offers impact resistance, which can help prevent injuries from heavy objects or machinery.

Low Maintenance and Long Lifespan

One of the key advantages of Duragrid fiberglass grating is its low maintenance requirements. Unlike steel grating, which can rust over time and require costly maintenance or replacement, Duragrid requires minimal upkeep. It also has a long lifespan, reducing the need for frequent replacements and saving businesses money in the long run.

Applications of Duragrid Fiberglass Grating

Industrial and Commercial Uses

Duragrid is commonly used in a wide range of industrial settings, such as factories, power plants, and chemical processing facilities. It is ideal for catwalks, platforms, stair treads, and walkways where high foot traffic or heavy equipment use is common. Its lightweight nature makes it easy to install in tight spaces or areas with limited access.

Use in Wet and Corrosive Environments

Duragrid’s resistance to corrosion makes it the perfect choice for environments exposed to moisture, chemicals, and harsh conditions. For example, wastewater treatment facilities, marine environments, and food processing plants can benefit from the durability and non-corrosive properties of Duragrid grating.

How Duragrid Fiberglass Grating Outperforms Other Grating Materials

Comparing Fiberglass to Steel Grating

While steel grating is widely used in industrial flooring, it is prone to corrosion and rust when exposed to moisture or chemicals. Duragrid, on the other hand, offers superior corrosion resistance and a much longer lifespan. Fiberglass is also much lighter than steel, which reduces installation time and costs.

Comparing Fiberglass to Aluminum Grating

Aluminum grating is another common flooring solution, but it is often more expensive than fiberglass and can be prone to damage under heavy loads. Duragrid fiberglass grating offers similar benefits without the high price tag, and it is also more durable and resistant to corrosion, making it a better option for many industries.

Conclusion

Duragrid fiberglass grating is the ultimate flooring solution for industries requiring durability, safety, and low maintenance. Its ability to withstand harsh environments, combined with its lightweight and non-corrosive properties, makes it a preferred choice for many commercial and industrial applications. If you’re considering a flooring upgrade for your workspace, Duragrid fiberglass grating could be the ideal solution for improving safety and reducing long-term maintenance costs.

By choosing Duragrid, businesses can ensure that they are making a sustainable investment that will stand the test of time and enhance workplace safety.