Introduction

Choosing the right FRP concrete curb angle can make all the difference in your construction or infrastructure project. FRP (fiber-reinforced polymer) curb angles are strong, lightweight, and highly resistant to corrosion, making them an attractive alternative to traditional materials like steel or aluminum. In this guide, we’ll explore why FRP curb angles are critical to a variety of applications and break down the key factors to consider when making your selection. Whether you are a contractor, engineer, or facility manager, understanding these essentials will set you up for success.

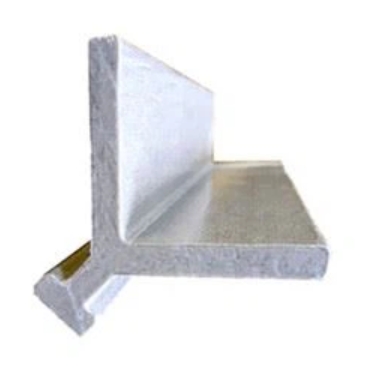

frp concrete curb angle

Understanding FRP Concrete Curb Angles

FRP Composition and Benefits

FRP, or fiber-reinforced polymer, typically comprises a resin matrix (such as polyester, vinyl ester, or epoxy) and reinforcing fibers (often fiberglass). This combination results in a material that delivers multiple advantages:

- High Strength-to-Weight Ratio: FRP is lighter than steel but offers comparable or even greater tensile strength.

- Corrosion Resistance: The resin matrix protects the fibers from moisture, chemicals, and UV exposure, extending the life of the curb angle.

- Low Maintenance: Unlike metal products that can rust, FRP curb angles generally require minimal upkeep.

According to a study by the American Concrete Institute (ACI), FRP composites can last up to four times longer than conventional materials in harsh environments. This durability ensures that once you install an FRP concrete curb angle, you can rely on it for the long haul without constant repairs or replacements.

Common Applications

FRP curb angles are used across a wide range of industries due to their excellent structural properties and resistance to damage. Some common applications include:

- Roadside Infrastructure: FRP angles help line and protect medians, sidewalks, and pathways.

- Bridges and Overpasses: Their corrosion resistance makes them ideal for harsh weather conditions.

- Commercial and Industrial Facilities: Plants handling corrosive chemicals often opt for FRP to maintain safety and extend operational life.

- Marine Projects: Docks, piers, and shoreline structures benefit from FRP’s resistance to salt and moisture.

Thanks to these advantages, FRP concrete curb angles have become a go-to choice whenever durability, lightweight construction, and corrosion resistance are priorities.

Key Factors to Consider When Selecting FRP Concrete Curb Angles

Load-Bearing Requirements

One of the first and most important questions to ask is: How much load will the curb angle need to support? If you’re designing for pedestrian traffic, a lighter-grade FRP angle may suffice. On the other hand, areas exposed to heavy vehicular traffic or machinery may require higher-grade angles. Confirming load specs before choosing an FRP curb angle ensures you invest in a product that can handle the weight demands without unnecessary expense.

In some cases, it helps to consult with a structural engineer or reference established load charts from FRP manufacturers. Properly matching load-bearing capacity to project requirements guarantees reliability and performance over time.

Environmental Conditions

Environmental factors significantly influence the performance and lifespan of your FRP concrete curb angle. Key considerations include:

- Moisture Exposure: High humidity or frequent rain can gradually affect materials if they’re not properly manufactured or installed.

- Temperature Fluctuations: Extreme hot or cold climates may impact the resin matrix, so choose an FRP formulation suited for these conditions.

- Chemical Exposure: If you are working in an industrial setting with harsh chemicals, make sure the chosen FRP resin is rated for chemical resistance.

Ask your supplier about the range of conditions their FRP curb angles can withstand. This preemptive research helps you avoid unexpected damage or maintenance costs down the road.

Cost-Effectiveness and Long-Term Value

While FRP materials can sometimes have a higher upfront cost compared to traditional steel or concrete curb angles, the long-term savings often justify the initial investment. Factors influencing total cost of ownership include:

- Reduced Maintenance: FRP’s corrosion resistance translates to fewer repairs and replacements.

- Longer Service Life: With proper installation and use, an FRP curb angle can outlast many competing materials.

- Improved Safety: Since FRP curb angles are non-conductive and slip-resistant, there’s typically less risk of electrical hazards or accidents.

When calculating your budget, factor in the costs saved on replacements, installation downtime, and the potential for reduced insurance claims, especially in high-traffic or industrial settings.

Steps to Evaluate Quality and Standards

Industry Standards and Testing

Not all FRP concrete curb angles are created equal. Look for products that meet recognized industry standards, such as those set by the American Society for Testing and Materials (ASTM). For instance, ASTM D7957 covers standards for solid round fiberglass reinforcing bars, and while not specifically curb angles, it’s indicative of the types of benchmarks quality FRP products should achieve. Some steps you can take include:

- Request Technical Data Sheets: Verify material properties like tensile strength, modulus of elasticity, and glass content.

- Check Quality Certifications: Ensure the manufacturer follows ISO 9001 or similar guidelines to maintain consistent product quality.

- Ask for Sample Test Reports: Reputable suppliers often share results from third-party labs confirming compliance with specific standards.

Working with Trusted Manufacturers

Selecting a reliable manufacturer for your FRP concrete curb angle ensures you benefit from superior craftsmanship and customer support. When vetting suppliers:

- Research Their Track Record: How long have they been in business? Do they specialize in FRP or offer a broad range of construction materials?

- Look for Client Testimonials: Positive feedback from similar projects can help validate quality and service.

- Evaluate Their Customer Service: Prompt responses, clear communication, and in-depth technical support are signs you’re working with a professional organization.

Remember that a high-quality FRP curb angle can save you money and frustration down the line, so choose a manufacturer that prioritizes reliability and customer satisfaction.

Installation Tips

Preparation and Tools

A smooth installation begins with the right preparation:

- Surface Inspection: Make sure the concrete or base surface is clean, level, and free from debris.

- Cutting Tools: FRP can be cut using specialized diamond-coated blades or carbide-tipped saws to maintain clean edges.

- Protective Gear: Wear gloves, safety glasses, and masks to avoid inhaling airborne particles from cutting or drilling FRP.

Working with FRP is straightforward when you follow the manufacturer’s guidelines. Double-check recommended cutting speeds and techniques to prevent damaging the curb angle during installation.

Ensuring Proper Alignment and Fixation

Alignment is crucial for both appearance and performance:

- Lay Out a Reference Line: Mark the exact placement using chalk lines or laser levels.

- Drilling and Anchoring: Pre-drill holes if needed, and use corrosion-resistant fasteners (like stainless steel) for securing the FRP angle in place.

- Sealants and Adhesives: In some cases, manufacturers may recommend using specific adhesives or sealants to further enhance bond and water resistance.

- Check for Uniformity: After the initial installation, survey the curb angles to ensure they are level and correctly aligned. Minor adjustments early on will prevent bigger issues later.

A well-executed installation not only boosts the curb angle’s appearance but also ensures optimal performance over its entire lifespan.

Conclusion

Selecting the right FRP concrete curb angle for your project involves weighing various factors—load requirements, environmental conditions, product quality, and installation procedures. By understanding FRP’s unique properties and verifying that your chosen curb angle meets high industry standards, you set the stage for a project that stands the test of time.

Whether you’re working on a roadside infrastructure upgrade or an industrial plant renovation, investing in the right FRP solution can lead to lower maintenance costs, longer service life, and improved safety. If you found this guide helpful, consider sharing it with colleagues and leaving a comment about your own experiences. Together, we can elevate best practices and harness the full potential of FRP in modern construction.