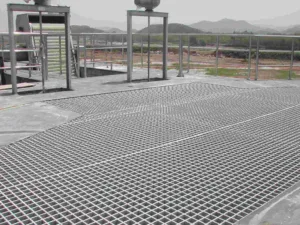

In the world of industrial flooring and construction, reinforced fiberglass grating has emerged as a leading solution for many applications. Its exceptional strength-to-weight ratio, durability, and corrosion resistance make it an ideal choice for a wide range of industrial and commercial settings. This article delves into the benefits, applications, and selection process for reinforced fiberglass grating, providing a detailed resource for professionals seeking reliable and efficient materials for their projects.

reinforced fiberglass grating

Understanding Reinforced Fiberglass Grating

Reinforced fiberglass grating, also known as FRP (Fiber Reinforced Polymer) grating, is a composite material made from a combination of resin and fiberglass. This blend is designed to offer a durable, lightweight, and highly resistant platform that can withstand harsh environmental conditions. Unlike traditional materials such as steel, FRP grating does not corrode, rust, or deteriorate quickly, making it a cost-effective and long-lasting solution.

Key Benefits of Reinforced Fiberglass Grating

- Durability and Longevity: FRP grating’s resistance to corrosion, impact, and UV light ensures a long service life with minimal maintenance.

- High Strength-to-Weight Ratio: It is significantly lighter than metal alternatives, reducing installation costs and structural requirements.

- Safety Features: With its slip-resistant surface and fire-retardant properties, reinforced fiberglass grating enhances workplace safety.

- Cost-Effectiveness: While the initial investment might be higher than some materials, the long-term savings in maintenance and replacement costs make it a financially sound choice.

Applications of Reinforced Fiberglass Grating

Due to its versatile properties, reinforced fiberglass grating is utilized in various sectors, including:

- Industrial Flooring: For factories and plants where chemical resistance and safety are paramount.

- Walkways and Platforms: In sectors such as oil and gas, marine, and water treatment plants.

- Architectural Applications: For aesthetically pleasing yet functional outdoor structures.

- Containment Systems: As a protective barrier in chemical handling areas.

Selecting the Right Fiberglass Grating

When choosing FRP grating for your project, consider the following factors to ensure optimal performance and compatibility:

- Load Requirements: Evaluate the weight and types of loads the grating must support to select the appropriate thickness and mesh size.

- Environmental Conditions: Determine the level of chemical, moisture, and UV exposure to choose the right resin type.

- Safety and Compliance: Ensure the grating meets relevant safety standards and building codes for your application.

Installation and Maintenance

The installation of fiberglass grating is straightforward, but it requires proper planning and preparation to ensure a secure fit and optimal performance. Regular inspections and cleaning will maintain the integrity and safety of the grating, contributing to its longevity.

Innovation in Fiberglass Grating

The industry continues to innovate, with manufacturers developing new resins and manufacturing techniques to enhance the performance and application range of FRP grating. These advancements promise to broaden the scope of fiberglass grating, making it an even more attractive option for future projects.

Conclusion

Reinforced fiberglass grating stands out as a superior choice for a multitude of applications, thanks to its durability, safety features, and cost-effectiveness. By understanding the specific needs of your project and selecting the appropriate type of FRP grating, you can ensure a successful implementation that meets your operational and financial objectives.