Introduction

When choosing grating for industrial and commercial projects, it’s crucial to select a material that meets the demands of your environment while providing durability, safety, and low maintenance. Open Mesh GRP (Glass Reinforced Plastic) grating has gained popularity as an alternative to traditional materials like steel, aluminum, and wood. Known for its lightweight strength, corrosion resistance, and non-slip properties, open mesh GRP grating is often a better fit for challenging settings. This article will compare open mesh GRP grating with traditional grating materials to help you make an informed decision.

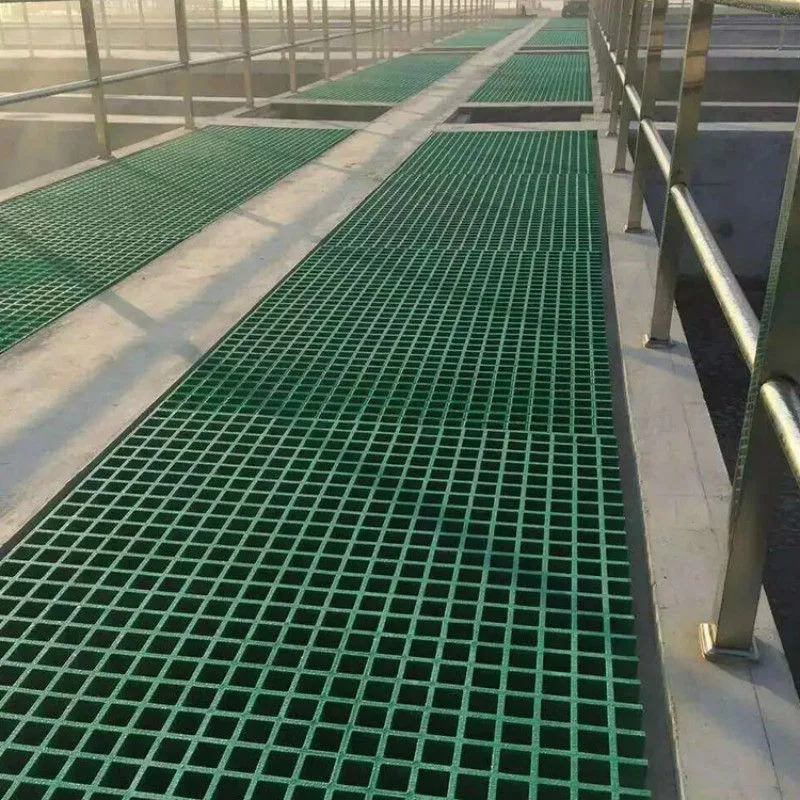

open mesh grp grating

What is Open Mesh GRP Grating?

Open mesh GRP grating is a type of grating material made from glass-reinforced plastic. Unlike traditional materials, GRP grating offers a combination of strength, lightness, and corrosion resistance, making it ideal for high-moisture or chemically harsh environments. The open mesh design allows liquids, air, and light to pass through freely, making it a safe and efficient choice for various applications.

How Open Mesh GRP Grating Differs From Other Types of GRP

GRP grating is available in different designs, but the open mesh version has unique advantages. Open mesh grating, as opposed to solid or covered GRP, provides excellent drainage and ventilation, which is essential in many industrial settings. This design also makes it lighter and easier to install.

How Open Mesh GRP Grating is Made

Open mesh GRP grating is manufactured through a process known as “pultrusion” or “molding.” These methods involve reinforcing plastic with fine glass fibers to form a matrix that’s durable yet lightweight. Once the structure is molded, it is cut into the desired shape, offering flexibility for different applications.

Key Properties of Open Mesh GRP Grating

Open mesh GRP grating has several key properties that make it an ideal choice for demanding environments:

- Lightweight Yet Strong: Despite its weight, GRP grating has a high load-bearing capacity, allowing for easy handling and installation without compromising strength.

- Corrosion and Chemical Resistance: This grating is resistant to rust, chemicals, and saltwater, making it perfect for marine and industrial use.

- Non-Conductive: Unlike metal grating, GRP is non-conductive, which reduces the risk of electrical hazards.

- Slip-Resistant Surface: The textured surface of GRP grating enhances traction, reducing slip and fall risks in wet or oily conditions.

Traditional Grating Materials: Pros and Cons

Traditional grating materials such as steel, aluminum, and wood are widely used but come with certain limitations. Understanding the pros and cons of these materials can help you assess whether they’re the best choice for your specific needs.

Steel Grating

- Pros: High strength, durable, and widely available.

- Cons: Prone to rust in humid or corrosive environments, conductive, and heavy, making installation more challenging.

Aluminum Grating

- Pros: Lighter than steel, corrosion-resistant, good for non-heavy duty applications.

- Cons: Not as strong as steel, limited lifespan in harsh industrial environments.

Wood Grating

- Pros: Lightweight and cost-effective for short-term use.

- Cons: Susceptible to rotting, warping, and insect damage, making it impractical for long-term or industrial applications.

Comparing Open Mesh GRP Grating to Steel Grating

When comparing open mesh GRP grating with steel grating, several differences stand out:

- Weight and Strength: GRP grating is much lighter than steel, which makes installation easier and less labor-intensive.

- Corrosion Resistance: Steel grating tends to corrode in damp or chemically aggressive environments, while GRP is naturally resistant to corrosion.

- Safety: GRP grating is non-conductive and slip-resistant, which enhances safety in industrial settings where workers are exposed to wet or oily floors.

Comparing Open Mesh GRP Grating to Aluminum Grating

Aluminum grating is another alternative, but it doesn’t match GRP in certain areas:

- Durability: GRP is often more durable in harsh conditions, where aluminum might weaken or corrode over time.

- Cost-Efficiency: Although aluminum is lighter than steel, GRP is even lighter and often more affordable in the long run due to its low maintenance needs.

Comparing Open Mesh GRP Grating to Wood Grating

Wood grating has historically been used in certain applications, but GRP has significant advantages:

- Longevity: GRP outlasts wood by years, particularly in wet or corrosive environments.

- Maintenance: Wood requires regular treatment to prevent decay, whereas GRP is virtually maintenance-free.

Applications of Open Mesh GRP Grating

Industrial: Open mesh GRP grating is ideal for factories, offshore platforms, and chemical plants, where durability and corrosion resistance are essential.

Commercial: It’s commonly used in walkways, decking, and public spaces, as the open mesh design provides safe and slip-resistant pedestrian access.

Niche Applications: GRP grating is also used in agriculture and marine environments where moisture exposure is common.

Cost Comparison: GRP Grating vs. Traditional Materials

While the upfront cost of GRP grating can be higher, its long-term savings are substantial due to minimal maintenance and a longer lifespan compared to steel or wood.

Environmental Benefits of Using Open Mesh GRP Grating

One of the standout advantages of open mesh GRP grating is its reduced environmental impact compared to traditional materials. This material is engineered to last longer, meaning fewer replacements and less waste. Additionally, the GRP production process is often more sustainable, producing less harmful emissions and requiring less energy than steel manufacturing.

- Longevity and Durability: Since GRP grating resists corrosion and decay, it requires fewer replacements over time, resulting in less material waste.

- Minimal Maintenance: GRP’s durability reduces the need for paints, coatings, or treatments, which minimizes environmental pollution from these substances.

- Reduced Energy Consumption: Producing GRP grating typically consumes less energy than manufacturing steel or aluminum grating.

By choosing GRP, industries and facilities can significantly lower their environmental footprint, aligning with sustainability goals and reducing long-term costs.

Installation of Open Mesh GRP Grating

Installing open mesh GRP grating is generally straightforward, especially compared to heavier materials like steel. Here are key steps and considerations to ensure a smooth installation process:

- Site Preparation: Make sure the installation surface is level and ready to support the grating. Open mesh GRP is flexible enough to fit various surface conditions.

- Measuring and Cutting: GRP grating can be easily cut on-site with basic power tools, unlike steel, which often requires specialized tools.

- Fixing and Fastening: Use corrosion-resistant fasteners to secure the grating. Most GRP grating installations include specially designed clips that hold the grating in place without compromising its structure.

- Safety Considerations: Always follow proper handling procedures, including wearing gloves and eye protection, as GRP edges can be sharp after cutting.

With its lightweight structure, open mesh GRP grating requires fewer personnel and equipment for installation, lowering labor costs and reducing setup time.

Maintenance and Lifespan of Open Mesh GRP Grating

One of the primary reasons industries are turning to open mesh GRP grating is its exceptionally low maintenance requirements. GRP is built to withstand tough conditions without needing frequent repairs or treatments.

- Corrosion Resistance: Unlike metal grating, which often requires protective coatings or galvanization, GRP is inherently corrosion-resistant and can handle long-term exposure to moisture and chemicals.

- Cleaning Requirements: Most dirt or contaminants can be easily rinsed off with water, and GRP’s non-porous surface minimizes debris buildup.

- Lifespan: In most industrial and commercial settings, GRP grating can last 20 years or more, depending on environmental exposure. This longevity reduces replacement needs, making GRP a cost-effective investment over time.

Thanks to its durability and minimal upkeep, open mesh GRP grating is perfect for facilities looking to cut down on maintenance labor and costs.

Safety Benefits of Open Mesh GRP Grating

Safety is a crucial consideration in industrial and commercial environments, and open mesh GRP grating provides several safety benefits:

- Slip Resistance: The open mesh design, combined with a textured surface, minimizes the risk of slips and falls, even in wet or oily conditions.

- Non-Conductive Properties: Unlike metal grating, GRP is non-conductive, which helps prevent electrical hazards, a significant advantage in settings where workers may come into contact with electrical equipment.

- Fire Retardance: Many GRP grating products are designed to be fire-retardant, providing extra protection in environments where fire hazards exist.

With its combination of slip resistance, non-conductivity, and fire-retardant options, open mesh GRP grating enhances safety for personnel and equipment alike.

FAQs About Open Mesh GRP Grating

- What loads can open mesh GRP grating support?

- GRP grating can support heavy loads, though the specific capacity varies depending on thickness and design. For industrial applications, always consult manufacturer specifications to ensure load capacity meets project requirements.

- Is open mesh GRP grating suitable for high-temperature environments?

- Yes, most GRP grating can withstand moderately high temperatures, but extreme heat may affect its structural integrity. Some manufacturers offer specialized high-temperature GRP options for such settings.

- How does open mesh GRP grating handle chemical exposure?

- GRP grating is highly resistant to a wide range of chemicals, making it suitable for use in factories, chemical plants, and other environments where chemical exposure is likely.

- Can GRP grating be used in outdoor settings?

- Absolutely. GRP grating is highly resistant to UV exposure and moisture, making it ideal for outdoor walkways, platforms, and decks.

- What are the color options available for open mesh GRP grating?

- GRP grating is available in a range of colors, often including gray, green, and yellow, which are frequently used in industrial environments for safety and visibility.

- How long does open mesh GRP grating last compared to steel grating?

- Open mesh GRP grating typically lasts 20+ years with minimal maintenance, often outlasting steel grating in corrosive or moist environments.

Conclusion

In summary, open mesh GRP grating provides several advantages over traditional materials like steel, aluminum, and wood. From corrosion resistance and lightweight strength to enhanced safety and minimal maintenance, GRP is a highly versatile solution for industrial, commercial, and even residential applications. While traditional grating materials each have their benefits, open mesh GRP grating offers a balance of durability, cost-efficiency, and environmental sustainability that’s hard to beat.

If you’re planning a project and looking for a material that delivers safety, longevity, and ease of installation, open mesh GRP grating might be the right choice for you. Consider making the switch to GRP for a more efficient, low-maintenance solution that stands the test of time.