Introduction to Mini Mesh GRP Grating

Mini mesh GRP (Glass Reinforced Plastic) grating is an innovative solution for a wide range of industrial and commercial applications. Known for its exceptional strength, lightweight nature, and superior resistance to harsh environmental conditions, it has quickly become a favorite among engineers and designers worldwide.

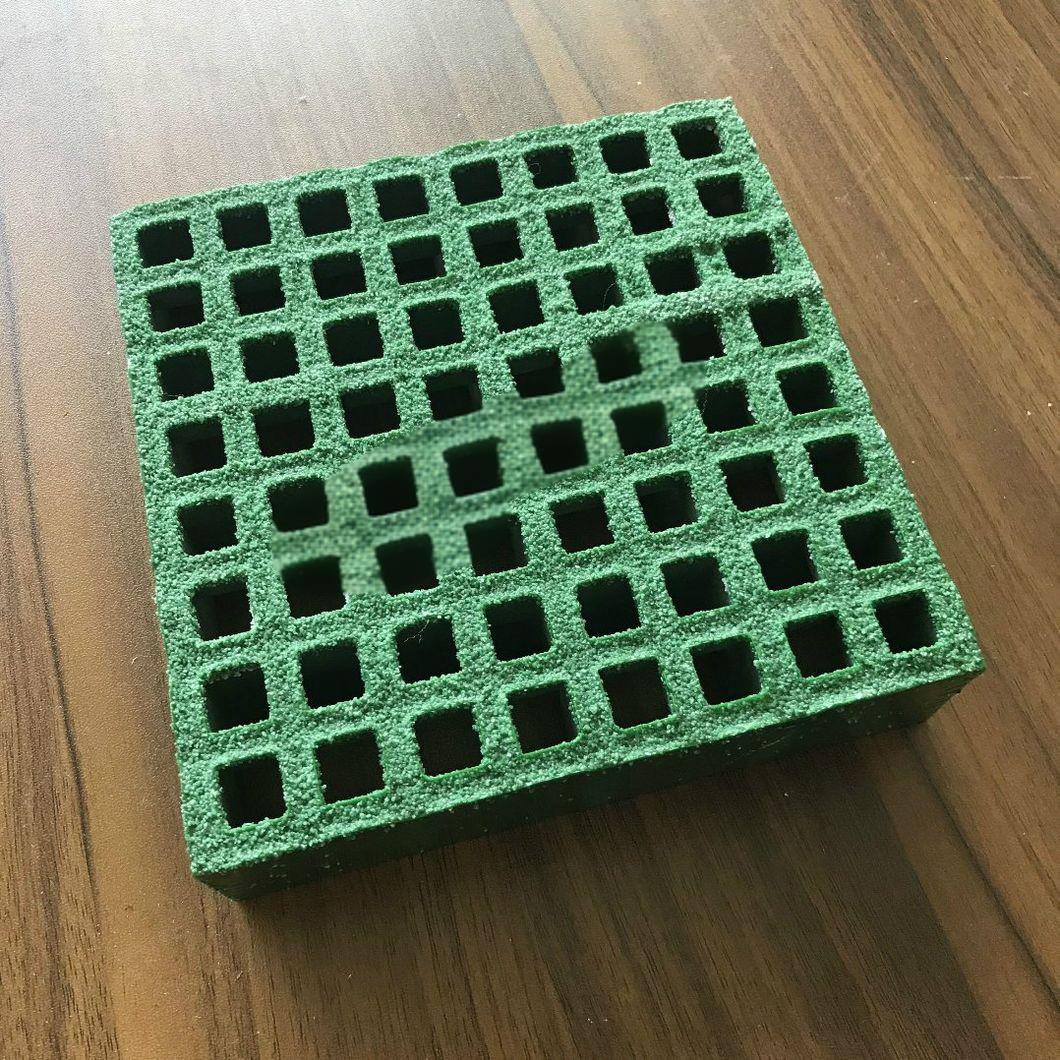

But what exactly is mini mesh GRP grating? Simply put, it’s a type of reinforced grating made from fiberglass and resin, forming a highly durable and versatile material. Its unique “mini mesh” design refers to the small aperture size, making it ideal for environments that demand a safe and slip-resistant surface.

With features like corrosion resistance, high load-bearing capacity, and ease of installation, mini mesh GRP grating outshines traditional materials like steel and aluminum. In this article, we’ll delve into its composition, benefits, applications, and much more.

mini mesh grp grating

Composition and Manufacturing Process

Materials Used in GRP Grating

The primary components of mini mesh GRP grating are:

- Fiberglass: Adds strength and durability while keeping the grating lightweight.

- Resin: Enhances resistance to corrosion, chemicals, and UV exposure.

How Mini Mesh GRP Grating is Manufactured

The manufacturing process involves a combination of molding and curing techniques:

- Fiberglass Mat Placement: Layers of fiberglass mats are arranged in molds.

- Resin Application: High-quality resin is poured into the molds, saturating the fiberglass.

- Curing: The material is cured under controlled conditions to ensure uniform strength and resilience.

- Cutting and Finishing: The grating is cut to size and finished to ensure smooth edges and consistent quality.

This process ensures that mini mesh GRP grating is not only robust but also aesthetically appealing.

Unique Features of Mini Mesh GRP Grating

1. Corrosion Resistance

One of the standout features of mini mesh GRP grating is its resistance to corrosion. Unlike metal gratings, it doesn’t rust when exposed to water, chemicals, or salt, making it ideal for marine and industrial environments.

2. Slip Resistance

The small apertures in the mini mesh design provide excellent traction, reducing the risk of slips and falls, even in wet or oily conditions.

3. Lightweight Yet Strong

Despite being lightweight, mini mesh GRP grating boasts impressive load-bearing capacity, making it a practical choice for applications requiring both strength and portability.

Benefits of Using Mini Mesh GRP Grating

1. Long-Term Cost Efficiency

While the initial cost of GRP grating might be higher than traditional materials, its low maintenance requirements and extended lifespan translate to significant savings over time.

2. Safety Features for Industrial Use

The anti-slip surface and non-conductive nature of GRP grating make it an excellent choice for environments where safety is a priority, such as factories, power plants, and walkways.

3. Environmental Friendliness

GRP grating is environmentally sustainable. Its durability reduces waste, and it is often made using eco-friendly manufacturing processes.

Common Applications

1. Industrial Environments

Mini mesh GRP grating is used in platforms, walkways, and stair treads in industries like oil and gas, chemical plants, and power generation.

2. Public Spaces and Pedestrian Areas

Its slip resistance and aesthetic appeal make it suitable for footbridges, parks, and urban infrastructure.

3. Marine and Offshore Settings

The corrosion-resistant nature of GRP grating makes it perfect for docks, piers, and offshore rigs.

Installation Process

1. Preparing for Installation

Before installation, ensure that the site is clean and the dimensions are measured accurately.

2. Tools and Techniques Used

Common tools include saws for cutting GRP panels and fasteners for securing them in place.

3. Common Challenges and Troubleshooting

Challenges like uneven surfaces or misaligned panels can be addressed by following manufacturer guidelines and using proper leveling techniques.

Mini Mesh GRP Grating vs. Traditional Materials

Comparison with Steel and Aluminum Grating

- Durability: GRP grating outlasts steel in corrosive environments.

- Weight: GRP is lighter than both steel and aluminum.

- Cost: GRP offers better long-term value due to reduced maintenance.

Advantages of GRP Over Traditional Materials

- Non-conductive and fire-retardant properties.

- Customizable in size, shape, and color.

Industry Standards and Certifications

To ensure quality and safety, mini mesh GRP grating must adhere to various standards, including:

- ISO 9001 for manufacturing quality.

- ASTM standards for load-bearing capacity and slip resistance.

Maintenance and Longevity

Cleaning and Maintenance Tips

- Regular cleaning with water and mild detergent keeps the surface free of debris.

- Inspect fasteners periodically to ensure they remain secure.

Expected Lifespan and Durability

With proper care, mini mesh GRP grating can last over 20 years, even in harsh environments.

Environmental Impact

Sustainability in Manufacturing

GRP gratings are made with minimal waste and often incorporate recycled materials.

Recycling and End-of-Life Considerations

At the end of its lifecycle, GRP grating can often be recycled into new products, reducing environmental impact.

Cost Analysis

Factors Affecting Price

- Size and thickness of the grating.

- Type of resin used (e.g., fire-retardant or UV-resistant).

- Customization and additional coatings.

Cost Comparison with Other Materials

While initially more expensive, GRP grating’s lower maintenance costs and extended lifespan make it a cost-effective choice.

Innovations in Mini Mesh GRP Grating

Latest Advancements in Design and Technology

Recent innovations include enhanced UV protection, integrated anti-microbial properties, and customizable designs.

Future Trends and Predictions

Expect further developments in sustainability, with GRP grating becoming even more eco-friendly and widely adopted.

Choosing the Right Mini Mesh GRP Grating

Factors to Consider

- Load requirements.

- Environmental conditions (e.g., exposure to chemicals or saltwater).

Customization Options Available

GRP grating can be tailored in terms of size, color, and surface finish to suit specific needs.

Real-World Case Studies

Examples of Successful Installations

- Offshore Rig: Improved safety and reduced maintenance costs.

- Urban Footbridge: Enhanced pedestrian safety with anti-slip surfaces.

Lessons Learned from Past Projects

Proper site preparation and adherence to installation guidelines ensure optimal performance.

Frequently Asked Questions (FAQs)

- What sizes are available for mini mesh GRP grating?

GRP grating is available in various sizes, typically customizable to meet project requirements. - Can it withstand extreme temperatures?

Yes, GRP grating performs well in both high and low temperatures. - How does it perform under heavy loads?

Its high strength-to-weight ratio allows it to handle significant loads without deformation. - What are the color options?

Common colors include gray, yellow, and green, but custom colors are also available. - Is GRP grating suitable for marine use?

Absolutely! Its corrosion resistance makes it ideal for marine applications. - How easy is it to install?

GRP grating is lightweight and easy to cut, making installation straightforward.

Conclusion and Final Thoughts

Mini mesh GRP grating combines strength, durability, and versatility, making it a top choice for a wide range of applications. Its unique properties, such as corrosion resistance and slip prevention, ensure both safety and longevity.

Ready to explore mini mesh GRP grating for your next project? Contact a supplier today and experience its unmatched benefits!