Molded fiberglass grating is revolutionizing industrial and architectural applications with its durability, strength, and corrosion resistance. Selecting the right manufacturer is not just about the product but also about the value, support, and sustainability they bring to your project. This guide will walk you through the essential criteria to help you make an informed decision.

molded fiberglass grating manufacturers

Understanding Molded Fiberglass Grating

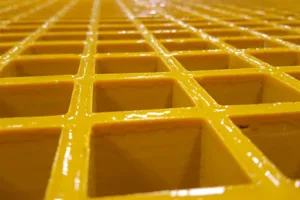

Molded fiberglass grating is a composite material made from fiberglass strands molded into a sturdy, grid-like structure. Its superiority over metal and wood includes corrosion resistance, non-conductivity, and a high strength-to-weight ratio, making it ideal for a wide range of environments.

Factors to Consider When Selecting a Manufacturer

Selecting the right manufacturer involves considering various factors such as quality, customization, pricing, environmental practices, and customer support. These factors ensure that the product meets your project’s specific needs while also aligning with broader operational and sustainability goals.

How to Evaluate Quality and Certifications

Quality is non-negotiable. Look for manufacturers with certifications like ISO 9001, which indicates adherence to quality management principles. Evaluating past projects and case studies can also give insights into a manufacturer’s capability to meet complex requirements.

Assessing Customization Capabilities

The ability to customize products to meet specific project requirements is crucial. Whether it’s unique dimensions, colors, or performance features, a good manufacturer should offer a range of customization options.

Analyzing Pricing and Value

While initial costs are important, consider the long-term value of the product. Molded fiberglass grating offers significant cost savings over time due to its durability and low maintenance requirements.

Environmental Sustainability Practices

Given the growing emphasis on sustainable practices, evaluate the environmental impact of a manufacturer’s operations. This includes the sourcing of materials and the environmental footprint of their manufacturing processes.

Evaluating Customer Service and Support

Strong customer support, from initial consultations to after-sales services, can significantly influence your project’s success. Assess the manufacturer’s responsiveness, support offerings, and willingness to provide guidance throughout the project lifecycle.

The Importance of Lead Times and Logistics

Understanding the manufacturer’s lead times and logistics capabilities is crucial for project planning. Delays can have cascading effects on project timelines and budgets.

Case Studies: Successful Partnerships

Examining real-life case studies of successful projects can provide valuable insights into a manufacturer’s capabilities and the potential challenges and solutions involved in similar projects.

Questions to Ask Potential Manufacturers

Prepare a list of questions covering quality certifications, customization options, environmental practices, and customer support to ensure all your bases are covered during the selection process.

Avoiding Common Pitfalls

Be wary of red flags such as lack of transparency, poor communication, and inadequate after-sales support, which can indicate potential issues down the line.

Future Trends in Molded Fiberglass Grating

Stay informed about the latest innovations and trends in the industry, such as advancements in materials technology and sustainability practices, to make a future-proof decision.

Conclusion

Choosing the right molded fiberglass grating manufacturer is pivotal to the success of your project. By carefully considering each of the outlined factors, you can ensure that your selection aligns with your project requirements, budget, and sustainability goals.