Introduction:

Fiberglass rebar corners have emerged as a popular alternative to traditional metal corners due to their exceptional durability and versatility. They are widely used in construction and repair projects to reinforce corners, edges, and joints. This article provides a comprehensive guide on installing fiberglass rebar corners, ensuring a seamless and long-lasting application.

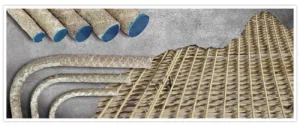

fiberglass rebar corners

What is Fiberglass Rebar?

Fiberglass rebar is a composite material made of glass fibers embedded in a resin matrix. It offers exceptional strength, lightweight properties, and resistance to corrosion and rust. These qualities make it an ideal choice for various construction applications, especially in areas prone to moisture and chemical exposure.

Advantages of Using Fiberglass Rebar Corners:

Fiberglass rebar corners provide numerous benefits, making them a preferred choice for construction professionals and DIY enthusiasts alike. Some of the key advantages include:

- Corrosion Resistance: Unlike traditional metal rebar, fiberglass rebar does not corrode, ensuring a longer lifespan for the structure.

- Lightweight: The lightweight nature of fiberglass rebar simplifies handling and installation, reducing labor costs and effort.

- Non-Conductive: Fiberglass rebar does not conduct electricity, making it safe for use in areas with electrical installations.

- Chemical Resistance: It is highly resistant to various chemicals, making it suitable for applications in harsh environments.

- Dimensional Stability: Fiberglass rebar remains stable under temperature variations, preventing expansion and contraction issues.

Preparing for Installation:

1. Tools and Materials Required:

Before starting the installation process, gather the necessary tools and materials:

- Fiberglass rebar corners

- Construction adhesive

- Caulking gun

- Tape measure

- Level

- Saw or utility knife

- Sandpaper

- Safety goggles and gloves

2. Surface Preparation:

Ensure the surface where the fiberglass rebar corners will be installed is clean, dry, and free from dust and debris. Smooth out any rough edges or uneven areas to achieve a flat and even surface.

Step-by-Step Guide to Install Fiberglass Rebar Corners:

1. Step 1: Apply Adhesive

Using a caulking gun, apply a generous amount of construction adhesive to the backside of the fiberglass rebar corner. Ensure even coverage, especially around the edges and corners.

2. Step 2: Position the Fiberglass Rebar Corner

Carefully place the adhesive-coated fiberglass rebar corner on the designated corner or edge. Use a level to ensure it is perfectly aligned and plumb.

3. Step 3: Secure and Finish

Press the fiberglass rebar corner firmly against the surface to ensure proper adhesion. Wipe off any excess adhesive using a clean cloth. Allow sufficient time for the adhesive to cure according to the manufacturer’s instructions.

Tips for a Successful Installation:

- Work in small sections to prevent the adhesive from drying out before placing the fiberglass rebar corner.

- Use a miter saw or a utility knife to cut the fiberglass rebar corner to the desired length and angle, if needed.

- Avoid applying excessive force on the corner during installation to prevent damage to the fiberglass material.

Conclusion:

Installing fiberglass rebar corners is a straightforward process that offers numerous advantages over traditional metal corners. The lightweight, corrosion-resistant, and durable nature of fiberglass rebar make it a reliable choice for construction projects. By following the simple three-step installation guide and the provided tips, you can ensure a successful and long-lasting application.

Frequently Asked Questions (FAQs):

FAQ 1: Can fiberglass rebar corners be used for both indoor and outdoor applications?

Yes, fiberglass rebar corners are suitable for both indoor and outdoor applications. They are designed to withstand various environmental conditions, including moisture, temperature fluctuations, and exposure to chemicals.

FAQ 2: Is fiberglass rebar suitable for high-load bearing applications?

Fiberglass rebar is known for its exceptional strength-to-weight ratio. While it may not be suitable for extremely heavy load-bearing applications, it is commonly used for reinforcement in various construction projects.

FAQ 3: How long does it take for the adhesive to cure?

The curing time for the construction adhesive can vary depending on the product and environmental conditions. It is best to refer to the manufacturer’s instructions for specific curing times.

FAQ 4: Can fiberglass rebar corners be painted?

Yes, fiberglass rebar corners can be painted to match the surrounding surface or blend with the overall aesthetic of the structure. However, it is essential to use paint suitable for fiberglass materials.

FAQ 5: Are fiberglass rebar corners cost-effective?

Fiberglass rebar corners may have a higher upfront cost compared to traditional metal corners. However, considering their long lifespan, low maintenance requirements, and resistance to corrosion, they can be a cost-effective investment in the long run.