The raw material of FRP pultrusion profiles is generally resin and FRP fiber, and then it is a colorless and transparent material, which should have low viscosity and low heat release performance. Some of the characteristics of FRP pultrusion profiles are indispensable.

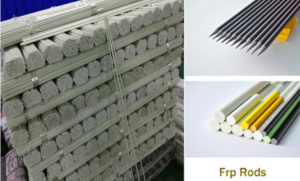

The FRP profiles produced are smooth and smooth, with good gloss, high strength, and toughness. If the use of inferior resin will be completely opposite inferior resin turbidities, high viscosity, high heat release, high shrinkage, relatively slow curing, compatibility is poor, the production of FRP profiles with pores, easy to fracture, poor strength and toughness. The second is the comparison of finished products. Good FRP profile products have no obvious cracks, fewer pores, bright and pure color, good transparency, a certain toughness and strength, good surface finish, long service life; The appearance of inferior FRP products has cracks, more pores, color impure gloss is not enough. Its service life is also short.

And for the inferior FRP pultrusion profile will appear some phenomena such as corrosion fracture after a few years of use, and the color also has some phenomena such as serious fading, this is the inferior FRP profile phenomenon.

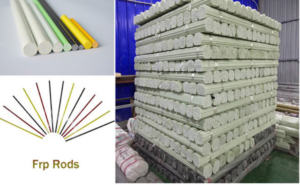

FRP pultrusion profile has a very wide range of applications, including light industry products, such as tent pole, umbrella pole, ski pole, hockey stick, beautify the antenna, fences, curtain rod, golf clubs, flagpole, building platform, handrail, pedestrian walkways, cable bridge, electrical insulation ladder, tool handles, offshore platform, power electric, cooling tower, petrochemical industry, paper industry, and so on.

Home