Introduction

Creating a fiberglass mold can be an intimidating task, especially if you’re new to the process. Fiberglass molds are widely used for creating durable, reusable forms for various applications—from automotive parts and boat components to customized hobby and artistic projects. While many beginners face challenges due to misinformation or a lack of guidance, following a clear and comprehensive checklist makes the entire process manageable and even enjoyable.

This article provides a complete beginner’s checklist detailing exactly how to create a fiberglass mold, ensuring successful results from your very first attempt.

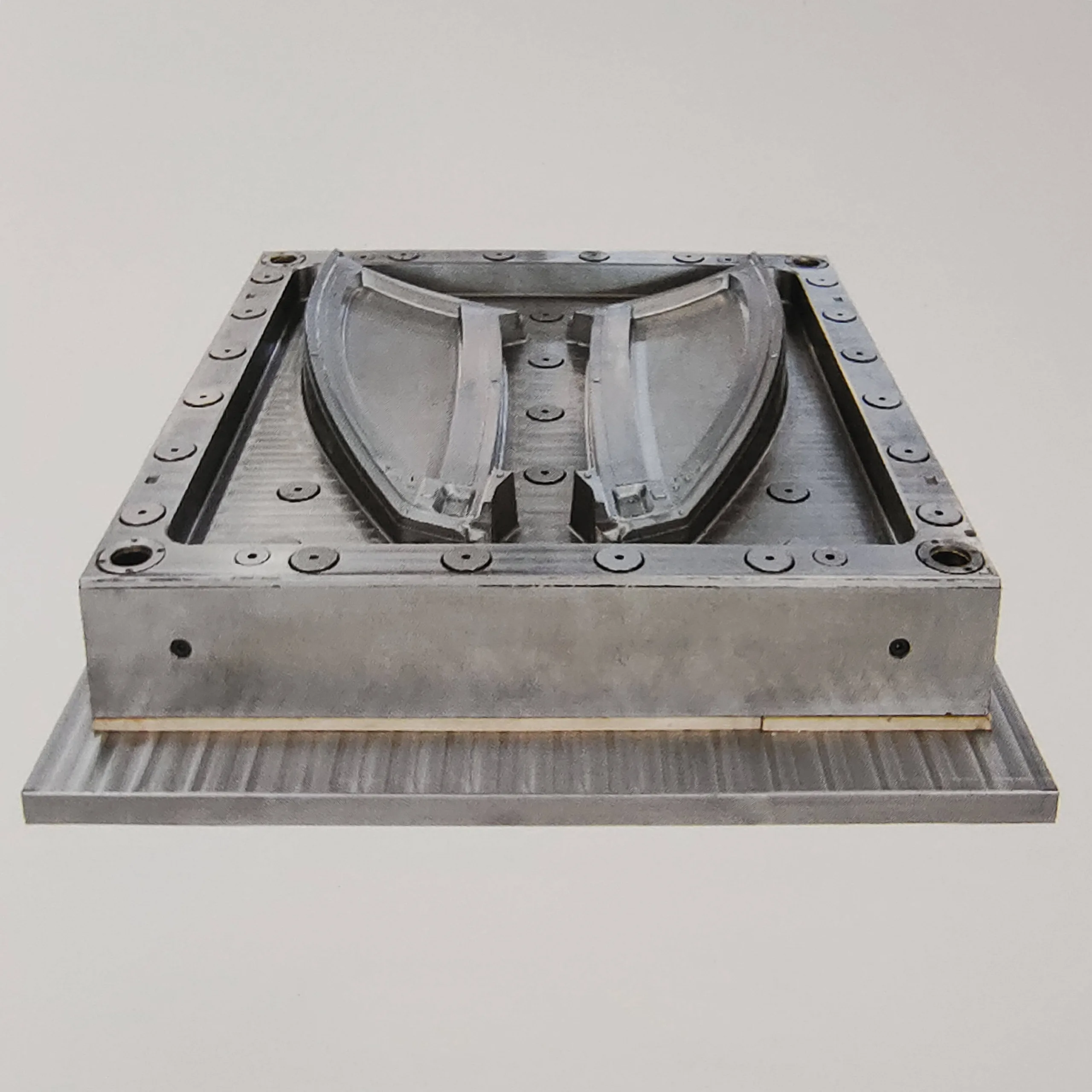

how to create a fiberglass mold

Understanding Fiberglass Molding Basics

What is a Fiberglass Mold?

A fiberglass mold is a reusable shell crafted from layers of fiberglass and resin. It allows for multiple reproductions of identical components with precise dimensions and fine surface details.

Common Applications of Fiberglass Molds

Fiberglass molds are extensively used in:

Automotive body kits and panels

Boat hulls and accessories

Architectural details and decorative elements

Hobby and model-making industries

Why Choose Fiberglass?

Durability and strength

Cost-effectiveness for multiple reproductions

Ability to capture intricate details

Lightweight and easily customizable

Materials and Tools Needed

Essential Materials Checklist

Fiberglass fabric or mat

Polyester or epoxy resin

Mold release agent

Gelcoat (for the mold surface)

Hardener (catalyst)

Sandpaper and polishing compound

Recommended Tools for Beginners

Paintbrushes and rollers

Mixing containers and stir sticks

Protective gloves and eyewear

Respirator mask

Measuring cups

Step-by-Step Beginner’s Checklist on How to Create a Fiberglass Mold

Step 1 – Designing Your Mold

Sketch your design and ensure dimensions and details are accurate.

Consider draft angles to make removal easier.

Step 2 – Preparing the Master (Plug)

Create or obtain a master plug that replicates your desired final product.

Smooth and polish the plug thoroughly; imperfections transfer directly to the mold.

Step 3 – Applying Mold Release Agent

Apply a generous, even coat of mold release agent onto the plug.

Allow sufficient drying time as instructed on the product label.

Step 4 – Applying Gelcoat Layer

Mix gelcoat and catalyst accurately following manufacturer’s guidelines.

Apply an even coat over the entire plug surface using a brush or sprayer.

Allow gelcoat to partially cure until tacky but not sticky to touch.

Step 5 – Adding Fiberglass Layers

Mix resin and hardener precisely according to instructions.

Lay fiberglass fabric or mat over the tacky gelcoat.

Apply resin using a brush or roller, saturating the fiberglass completely.

Add multiple layers, ensuring each is well-saturated and bubble-free.

Step 6 – Curing and Demolding

Allow the mold to cure fully (typically 24–48 hours).

Carefully separate the mold from the plug by gently flexing or prying at the edges.

Inspect for imperfections; sand and polish as necessary.

Common Mistakes Beginners Should Avoid

Incorrect Mold Preparation

Failure to thoroughly clean or smooth the plug leads to a flawed mold.

Not using or incorrectly applying mold release agents causes sticking.

Poor Mixing Ratios

Incorrect resin-to-hardener ratios result in weak molds that crack or fail prematurely.

Always measure carefully and follow product specifications closely.

Improper Layering Technique

Applying too few or uneven fiberglass layers creates structural weaknesses.

Always overlap layers adequately and smooth out air pockets immediately.

Pro Tips for Better Results

Safety Precautions

Always wear gloves, safety goggles, and a respirator mask.

Work in a well-ventilated area to reduce inhalation risks.

Achieving a Smooth Finish

Sand and polish the mold interior thoroughly to achieve a high-quality, professional surface.

Consider using finer grades of sandpaper progressively for the best results.

Storage and Maintenance of Molds

Store molds in a cool, dry environment away from direct sunlight.

Regularly inspect molds for cracks or wear, making repairs promptly.

Conclusion

Now you have a detailed beginner’s checklist for successfully creating your first fiberglass mold. By carefully following each step—from proper design and preparation to application and curing—you’ll quickly build confidence and skill in mold-making. Remember, practice makes perfect; don’t be discouraged by early mistakes, and always prioritize safety.

Did you find these steps helpful? Share your fiberglass mold-making experience or ask questions in the comments below. And don’t forget to share this guide with fellow hobbyists or aspiring professionals!