Introduction

If you’re a car enthusiast or someone involved in automotive customization, understanding how to create a fiberglass hood mold is essential for achieving precise, durable, and lightweight results. Fiberglass is often the material of choice for making hoods because of its strength and versatility. This guide will walk you through the step-by-step process of creating your very own fiberglass hood mold, ensuring that it’s durable, professional, and ready for use.

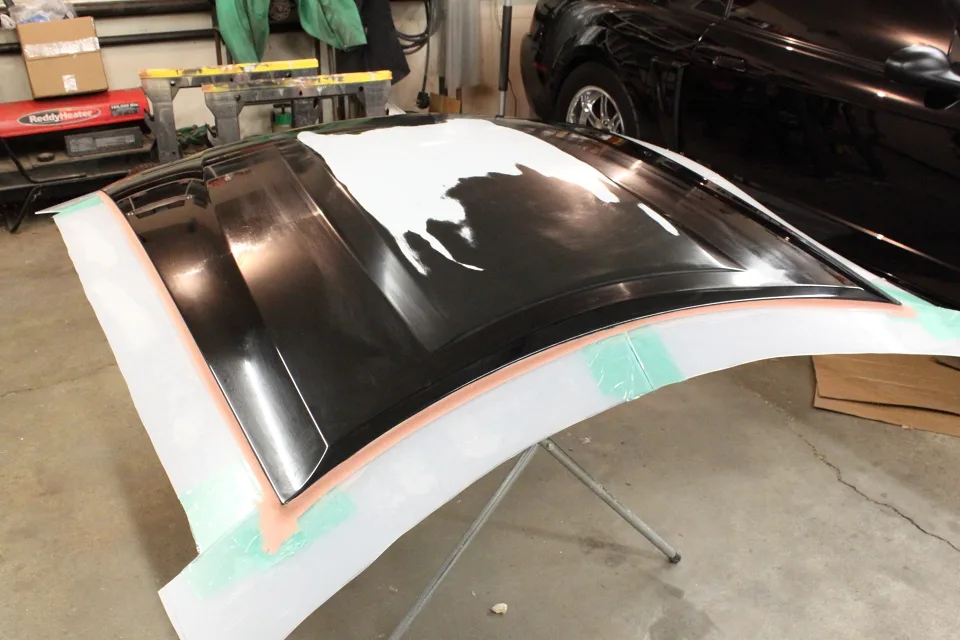

fiberglass hood mold

Understanding Fiberglass Hood Molds

What is a Fiberglass Hood Mold?

A fiberglass hood mold is a negative impression or form used to create a duplicate or custom hood for a vehicle. The mold is made from a variety of materials, but fiberglass is the most common due to its lightweight and durable qualities. The mold itself is an exact replica of the desired hood shape, and once it is created, it can be used to make numerous copies or custom versions.

Why Choose Fiberglass?

Fiberglass is known for its strength and flexibility. It’s resistant to corrosion, which is vital when creating automotive parts that may be exposed to harsh elements. Additionally, fiberglass can be molded into complex shapes, offering the versatility needed in custom designs. It’s also relatively easy to work with once you understand the basics.

Materials and Tools Needed

Essential Materials for Making a Fiberglass Hood Mold

To make a durable fiberglass hood mold, you’ll need the following materials:

- Fiberglass cloth: The base material that forms the structure of the mold.

- Resin: The liquid that binds the fiberglass cloth together when it hardens.

- Gel coat: Used to provide a smooth, glossy finish on the mold’s surface.

- Release agent: A vital product to ensure the mold can be removed easily after curing.

Tools You’ll Need for the Job

You’ll also need some essential tools to complete your project:

- Safety gear: Gloves, safety glasses, and a respirator mask to protect yourself from harmful fumes and dust.

- Cutting tools: Scissors or rotary cutters to trim fiberglass cloth.

- Mixing equipment: Containers for mixing resin and hardeners, along with a stirring stick.

- Brushes: For applying resin and gel coat evenly.

Step-by-Step Guide to Creating Your Fiberglass Hood Mold

Preparing the Surface for Molding

Before you begin laying the fiberglass, ensure the surface of the hood is clean and smooth. Use a degreaser or mild detergent to remove dirt, grease, and oils. Once the surface is dry, apply a release agent to prevent the fiberglass from sticking to the original surface.

Laying the Fiberglass Layers

Start by mixing the resin according to the manufacturer’s instructions. Cut the fiberglass cloth into manageable pieces and begin layering them over the prepared surface. Using a brush, apply resin to each layer of fiberglass, ensuring it soaks through completely. Repeat the layering process until you have at least three to four layers for durability.

Curing and Removing the Mold

Allow the mold to cure for the recommended time. This typically takes several hours, but the resin must fully harden before you attempt to remove the mold. Once it’s cured, carefully remove the mold from the surface. If done correctly, the fiberglass will retain the shape of the hood and can be used for future projects.

Common Issues and How to Avoid Them

Air Bubbles and Imperfections

Air bubbles can form between layers of fiberglass, which can compromise the strength of the mold. To avoid this, always ensure that the resin is applied smoothly and work out any air pockets by gently pressing on the fiberglass with a brush or roller.

Improper Curing and Handling

Improper curing can result in a weak mold that may crack or break easily. Follow the resin manufacturer’s instructions carefully and avoid rushing the curing process. Additionally, ensure that you handle the mold gently to prevent cracks during the removal process.

Tips for Maintaining and Using Your Fiberglass Hood Mold

How to Clean and Maintain Your Mold

After use, clean the mold by gently removing any debris and wiping it down with a cloth soaked in a mild cleaning solution. Store the mold in a cool, dry place to prevent it from warping or cracking.

Using the Mold for Vehicle Customization

Once your mold is ready, you can use it to create replacement hoods or custom-designed hoods for your vehicle. This is particularly useful for car restoration projects, or if you’re looking to create a one-of-a-kind design for a show car.

Conclusion

Creating a fiberglass hood mold may seem daunting at first, but with the right materials, tools, and a little patience, you can achieve impressive results. By following this step-by-step guide, you’ll be able to craft a durable and functional mold that will serve you well in your automotive customization projects. Remember, precision is key, and taking your time will pay off in the quality of the final product.

Call to Action: Have you made a fiberglass hood mold before, or are you planning to? Share your experiences or ask any questions in the comments below! Don’t forget to share this guide with fellow enthusiasts who might find it helpful.