Fiberglass I-beams are a type of structural support that is commonly used in construction, particularly in the construction of bridges, buildings, and other structures. They are made of a composite material consisting of fiberglass reinforced with plastic, which makes them lightweight, strong, and durable. While fiberglass I-beams are relatively easy to install, it is important to follow proper procedures in order to ensure a secure and stable connection.

Fiberglass I Beams

Steps to Connect Fiberglass I Beams:

- The first step in connecting fiberglass I-beams is to gather all of the necessary materials and tools. You will need a drill, drill bits, screws, nuts and bolts, washers, and any other necessary connectors or fasteners. You should also have a tape measure, a level, and a square to ensure that everything is properly aligned.

- Next, you will need to determine the proper placement for the I-beams. This will typically be determined by the design and specifications of the structure you are building, and it is important to follow these carefully to ensure that the structure is stable and safe. You should measure and mark the location of the I-beams on the supporting structure, and use a level and square to ensure that they are properly aligned.

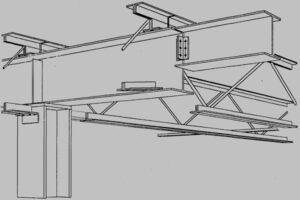

- Once you have determined the proper placement for the I-beams, it is time to begin the actual connection process. There are several methods that can be used to connect fiberglass I-beams, including the use of screws, bolts, and other fasteners. The most common method is to use screws, which can be inserted through pre-drilled holes in the I-beams and into the supporting structure. It is important to use screws that are long enough to securely fasten the I-beams to the structure and to use washers to distribute the load and prevent the screws from pulling through.

- If you are using bolts to connect the I-beams, you will need to drill holes in both the I-beams and the supporting structure, and then insert the bolts through the holes and secure them with nuts. It is important to use bolts that are the proper size and strength for the load that the I-beams will be carrying, and to tighten the nuts securely to ensure a strong connection.

- In addition to using screws or bolts, you may also need to use other types of connectors or fasteners to connect the I-beams to the supporting structure. These may include brackets, plates, or other types of hardware that are specifically designed for use with fiberglass I-beams. It is important to follow the manufacturer’s instructions when using these types of connectors, as they may require special installation techniques or tools.

- Once you have connected the I-beams to the supporting structure, it is important to check the connections to ensure that they are secure and properly aligned. You should use a level and square to verify that the I-beams are straight and properly aligned, and you should check the screws and bolts to make sure that they are tightened properly and that the washers are in place. If any of the connections are not secure or properly aligned, you will need to make adjustments or add additional fasteners to ensure that the structure is stable and safe.

In conclusion, connecting fiberglass I-beams is a relatively straightforward process that requires the proper tools, materials, and techniques. By following these steps and taking the time to properly align and secure the I-beams, you can ensure that your structure is strong, stable, and safe.