Fiberglass rebar has gained significant popularity in various construction projects due to its lightweight, corrosion resistance, and high tensile strength properties. Choosing the right fiberglass rebar supplier is crucial to ensure the success of your project. With a plethora of suppliers available, it’s essential to make an informed decision. In this article, we’ll guide you through the process of selecting the best fiberglass rebar supplier for your project needs.

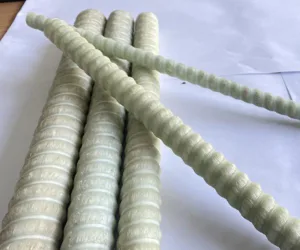

fiberglass rebar supplier

1. Understanding the Importance of Fiberglass Rebar

Fiberglass rebar offers a range of benefits, including its non-corrosive nature, high strength-to-weight ratio, and resistance to chemicals. Understanding these advantages will help you appreciate the significance of choosing the right supplier.

2. Evaluating Supplier Expertise and Experience

Look for suppliers with substantial experience in the fiberglass industry. Established companies like Unicomposite have years of expertise, ensuring they understand the nuances of producing and delivering quality fiberglass products.

3. Quality Assurance and Certifications

Reputable suppliers adhere to strict quality control processes and hold certifications like ISO 9001-2008. These certifications indicate a commitment to maintaining high-quality standards in their products.

4. Customization and Project Compatibility

Every project has unique requirements. Opt for a supplier that offers customization options, ensuring the fiberglass rebar aligns perfectly with your project’s specifications.

5. Range of Fiberglass Products Offered

A diverse product range showcases the supplier’s versatility. Suppliers like Unicomposite offer standard fiberglass profiles as well as customized solutions for various applications.

6. Technological Capabilities

Suppliers with advanced production technology can offer innovative solutions and precise products. Inquire about the supplier’s technological capabilities before making a decision.

7. Customer Reviews and Reputation

Online reviews and word-of-mouth recommendations provide insights into a supplier’s reputation. Positive feedback indicates a track record of customer satisfaction.

8. Cost-effectiveness and Budget Consideration

While cost shouldn’t be the sole factor, it’s essential to find a supplier that offers competitive prices within your budget constraints.

9. Timely Delivery and Logistics

Delays in supply can impact your project’s timeline. Choose a supplier with a track record of on-time deliveries and efficient logistics.

10. Environmental Considerations

Sustainability is crucial in modern construction. Opt for a supplier that follows environmentally friendly practices in their production processes.

11. Communication and Customer Support

Clear communication and responsive customer support ensure a smooth collaboration. A supplier who values effective communication can address concerns promptly.

12. Long-term Partnerships

Building a long-term partnership with a reliable supplier benefits future projects. Look for a supplier interested in fostering a lasting relationship.

13. Comparing Multiple Suppliers

Don’t settle for the first supplier you come across. Compare multiple options to make an informed decision based on your project’s specific needs.

14. Making the Final Decision

After thorough evaluation, narrow down your choices and make the final decision based on a supplier’s alignment with your project requirements.

15. Conclusion

Choosing the best fiberglass rebar supplier involves a comprehensive assessment of various factors. Unicomposite, for example, stands out as a specialized FRP supplier with a track record of quality, customization, and customer satisfaction. By considering aspects such as expertise, quality, customization, and reputation, you can confidently select a supplier that contributes to the success of your construction project.

Frequently Asked Questions

1. What are the benefits of using fiberglass rebar in construction projects? Fiberglass rebar offers benefits such as corrosion resistance, lightweight construction, and high tensile strength, making it an ideal choice for various projects.

2. How do I know if a supplier’s products meet quality standards? Reputable suppliers hold certifications like ISO 9001-2008, indicating adherence to stringent quality control processes.

3. Can I customize fiberglass rebar according to my project’s specifications? Yes, many suppliers offer customization options to ensure the fiberglass rebar aligns with your project’s unique requirements.

4. What role does technological advancement play in fiberglass rebar production? Advanced technology allows suppliers to produce precise and innovative fiberglass rebar solutions that meet diverse project needs.

5. Why is building a long-term partnership with a supplier important? Long-term partnerships ensure consistent product quality, reliable deliveries, and efficient collaboration for future projects.