Choosing the right fiberglass grating manufacturer is crucial for the success of your project. From load-bearing capacities to customization options, the decision involves a careful evaluation of various factors. Let’s dive into the key considerations that will guide you in selecting the best manufacturer for your fiberglass grating needs.

fiberglass grating manufacturer

Introduction

What is Fiberglass Grating?

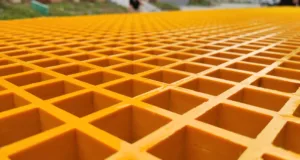

Fiberglass grating is a versatile and durable material widely used in construction, industrial, and commercial projects. It offers a lightweight alternative to traditional materials like steel while maintaining excellent strength and corrosion resistance.

Importance of Choosing the Right Manufacturer

The quality of your fiberglass grating depends significantly on the manufacturer. Opting for the right one ensures the longevity and performance of the grating in your specific project.

Understanding Your Project Needs

Identifying Project Requirements

Before selecting a manufacturer, identify the specific requirements of your project. Consider factors such as the type of environment, load-bearing needs, and any unique project specifications.

Specifying Load-Bearing Capacities

Different projects demand varying levels of load-bearing capacities. Ensure the manufacturer can provide grating solutions that align with your project’s specific load requirements.

Quality Standards and Certifications

Industry Standards for Fiberglass Grating

Look for manufacturers that adhere to industry standards for fiberglass grating. This ensures that the grating meets the necessary safety and performance benchmarks.

Certifications to Look for in a Manufacturer

Certifications such as ISO and ASTM are indicators of a manufacturer’s commitment to quality. Verify the presence of these certifications before making a decision.

Material Selection

Types of Fiberglass Grating Materials

Manufacturers offer different types of fiberglass grating materials. Understand the properties of each material and select the one that best suits your project’s requirements.

Corrosion Resistance and Durability

Evaluate the corrosion resistance and overall durability of the materials offered by the manufacturer. This is crucial, especially in projects with exposure to harsh environmental conditions.

Customization Options

Tailoring Grating Solutions to Your Project

The ability to customize grating solutions is essential. Choose a manufacturer that can tailor the grating to your project’s specific dimensions, colors, and surface finishes.

Color, Size, and Surface Options

Consider the variety of color, size, and surface options available. A manufacturer offering a range of choices allows you to meet aesthetic and functional preferences.

Cost Considerations

Balancing Quality and Budget

While cost is a significant factor, it should not compromise the quality of the fiberglass grating. Strike a balance between budget considerations and the overall quality of the product.

Hidden Costs to Be Aware Of

Be aware of hidden costs such as maintenance, installation, and potential replacements. A transparent manufacturer will provide a comprehensive cost analysis.

Manufacturer’s Reputation

Researching Manufacturer Reviews

Explore reviews and testimonials from previous customers. This provides insights into the manufacturer’s track record and customer satisfaction.

Seeking Recommendations and Testimonials

Reach out to industry experts or colleagues for recommendations. Personal testimonials can be invaluable in making an informed decision.

Communication and Customer Service

Accessibility and Responsiveness

Choose a manufacturer that is accessible and responsive to your queries. Effective communication is crucial for a smooth collaboration.

Understanding Warranty and Support Policies

Review the manufacturer’s warranty and support policies. A manufacturer confident in their products will offer robust warranty coverage and reliable support.

Sustainability Practices

Eco-Friendly Manufacturing Processes

Consider manufacturers with eco-friendly manufacturing processes. Sustainable practices contribute to the overall environmental responsibility of your project.

Recycling and Disposal Considerations

Inquire about the manufacturer’s approach to recycling and disposal. Responsible practices ensure minimal environmental impact after the project’s completion.

Project Timeline and Delivery

Assessing Lead Times

Evaluate the manufacturer’s lead times to ensure they align with your project schedule. Timely delivery is crucial to avoiding delays.

Ensuring Timely Delivery

Clarify the manufacturer’s commitment to timely delivery. Delays can impact project timelines, so choose a manufacturer with a proven track record of punctual deliveries.

Case Studies and Past Projects

Reviewing Manufacturer’s Portfolio

Examine the manufacturer’s portfolio and case studies. This provides a real-world understanding of their capabilities and the successful completion of similar projects.

Examining Similar Projects

Look for manufacturers with experience in projects similar to yours. Familiarity with the specific requirements of your project is a valuable asset.

Future Expansion and Maintenance

Planning for Future Additions

Consider future expansion plans and the manufacturer’s ability to provide additional grating if needed. A manufacturer that supports future project growth is advantageous.

Maintenance Requirements

Understand the maintenance requirements of the chosen grating. Manufacturers offering low-maintenance solutions can save you time and resources in the long run.

Comparative Analysis

Evaluating Multiple Manufacturers

Conduct a comparative analysis of multiple manufacturers. This involves a side-by-side comparison of their offerings, reputation, and overall suitability for your project.

Creating a Comparison Matrix

Develop a comparison matrix to visually assess and compare the strengths and weaknesses of each manufacturer. This aids in making an informed and objective decision.

Industry Trends and Innovations

Staying Ahead of Technological Advancements

Choose a manufacturer that stays abreast of industry trends and technological advancements. This ensures that your project benefits from the latest innovations in fiberglass grating.

Future-Proofing Your Project

Consider how well the manufacturer’s products can adapt to future industry changes. Future-proofing your project involves selecting materials and solutions that remain relevant over time.

Conclusion

In conclusion, choosing the best fiberglass grating manufacturer involves a comprehensive evaluation of project needs, quality standards, customization options, cost considerations, and the manufacturer’s reputation. By considering these factors, you ensure a successful and durable solution for your project.

FAQs

- Can I install fiberglass grating myself, or do I need professional assistance?

Installing fiberglass grating is generally straightforward, but for larger projects, professional assistance is recommended to ensure proper installation and compliance with safety standards.

- What is the typical lifespan of fiberglass grating?

The lifespan of fiberglass grating varies based on factors such as environmental conditions and maintenance. On average, it can last 20-30 years.

- Do all manufacturers provide customization options for color and size?

Not all manufacturers offer the same level of customization. It’s essential to choose a manufacturer that can tailor the grating to your specific project requirements.

- How do I determine the load-bearing capacity needed for my project?

Consult with a structural engineer to assess the load-bearing requirements based on your project specifications, ensuring the chosen grating meets safety standards.

- Are there any ongoing maintenance requirements for fiberglass grating?

While fiberglass grating is low-maintenance, regular inspections and cleaning may be necessary, depending on the environmental conditions of your project site.