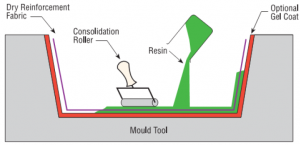

Hand lay-up process is also called contact forming process. It is a process of laying Fiberglass fabric and resin alternately on the mould by hand, and then solidifying them into FRP products.

Hand Lay-up Technology on FRP

Technological Introduction:

Advantages: the molding is not limited by the product size and shape, and it is suitable for the production of products with large size, small batch and complex shape. Simple equipment, less investment and quick effect. Moreover, the process is simple and the production technology is easy to master, and the production can be carried out only after short-term training. It is easy to meet the needs of FRP product design, and can add reinforcement materials in different parts of the product; the product has high resin content and good corrosion resistance.

Craft Progress:

Brush the resin mixture containing curing agent on the mold, and then lay a layer of fiber fabric cut according to the requirements on it. Press the fabric with a brush, press roller or scraper to make it evenly dip and eliminate bubbles. Then brush the resin mixture and lay the second layer of fiber fabric, and repeat the above process until the required thickness is reached. Then, under a certain pressure, heat curing (hot press forming) or heat curing (cold press forming) is used to cure the resin system, and finally the composite products are demoulded.