The advantages of the FRP hand layup process:

1) Complicated equipment is not required, it just needs simple mould and tools, so less investment, quick effect, and i’s suitable for the development of township enterprises in china;

2) Production technology is easy to master, after a short training, it can be mastered, but it’ll take a long time experience and study to achieve extremely good product

3) The production of FRP products are not limited by size and shape, such as: large cruise ships, round roof, sink, etc.;

4) It can be joint with other materials (such as: metal, wood, foam, etc.) at the same time;

5) For some of the large products (such as: large can, large roof) can be produced on the spot.

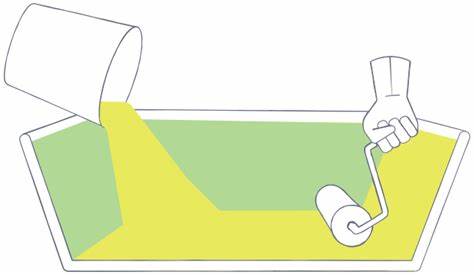

Hand Lay-up Process

FRP hand layup process disadvantages:

1) Compared with FRP pultrusion process, pulwinding process and filament winding process, he production efficiency is lower, the speed is slow, the production cycle will be a little longer, so it’s not suitable for the bulk production of the product;

2) Product quality is not as stable machine. Because of the difference of the level of operating personnel and the production of environmental conditions, the stability of product quality is not very good;

3) There is powder and smells in production environment. Therefore, hand lay up molding process has its advantages and can’t be replaced by other methods, the existing shortcomings should be overcome in operation process.

Fiberglass hand lay-up products application is wide, such as sports, building construction, corrossioin resistant products, etc