Introduction to Grating Fiberglass

Fiberglass grating is a versatile material widely used in various industries due to its exceptional properties. This guide will delve into the intricacies of grating fiberglass, exploring its types, benefits, applications, and much more.

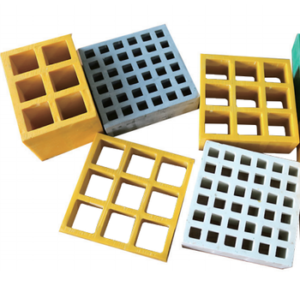

grating fiberglass

Overview of Fiberglass Grating

Fiberglass grating, often referred to as FRP (Fiber Reinforced Plastic) grating, is a composite material made from fiberglass and resin. It is known for its durability, lightweight, and resistance to corrosion, making it an ideal choice for many applications.

Importance in Various Industries

Fiberglass grating plays a crucial role in industries such as chemical processing, marine, and construction, where traditional materials may fail due to harsh environmental conditions. Its unique properties make it indispensable for creating safe and efficient workspaces.

What is Grating Fiberglass?

Definition and Components

Grating fiberglass is a composite material that combines fiberglass rovings and a resin matrix. The fiberglass provides strength and flexibility, while the resin offers protection against environmental damage.

Manufacturing Process

The production of fiberglass grating involves two primary methods: molding and pultrusion. In the molding process, fiberglass is placed in a mold and saturated with resin. In pultrusion, continuous fiberglass strands are pulled through a resin bath and a heated die to form the grating.

Types of Fiberglass Grating

Molded Fiberglass Grating

Molded fiberglass grating is produced in a mold and offers bi-directional strength. It is ideal for applications requiring high corrosion resistance and lightweight properties.

Pultruded Fiberglass Grating

Pultruded grating is made by pulling continuous fiberglass strands through a resin bath and a die. This type of grating has high strength and stiffness, making it suitable for heavy load applications.

Phenolic Fiberglass Grating

Phenolic grating is known for its fire resistance and low smoke production, making it perfect for offshore and shipboard use where fire safety is paramount.

Advantages of Fiberglass Grating

Durability

Fiberglass grating is incredibly durable, withstanding harsh environments and heavy loads without degrading.

Corrosion Resistance

Unlike metal grating, fiberglass does not corrode, making it ideal for use in corrosive environments like chemical plants and marine settings.

Lightweight Properties

Being lightweight, fiberglass grating is easy to handle and install, reducing labor costs and installation time.

High Strength

Despite its lightweight nature, fiberglass grating offers high strength and can support substantial loads, making it a versatile option for various applications.

Applications of Fiberglass Grating

Industrial Uses

In industrial settings, fiberglass grating is used for flooring, walkways, and platforms, providing a safe and durable surface that withstands heavy traffic and harsh conditions.

Marine Environments

Marine environments benefit greatly from fiberglass grating’s resistance to saltwater corrosion, making it ideal for docks, ship decks, and offshore platforms.

Commercial Applications

Commercial buildings use fiberglass grating for ventilation grilles, trench covers, and stair treads, combining functionality with aesthetic appeal.

Residential Uses

In residential areas, fiberglass grating is used for decks, patios, and pool surrounds, offering a non-slip, maintenance-free solution.

Fiberglass Grating vs. Traditional Materials

Fiberglass vs. Steel Grating

Steel grating, while strong, is prone to rust and corrosion, especially in moist environments. Fiberglass grating offers a longer lifespan and requires less maintenance.

Fiberglass vs. Aluminum Grating

Aluminum grating is lightweight but lacks the corrosion resistance and strength of fiberglass grating, making the latter a more durable option for demanding applications.

Design Considerations for Fiberglass Grating

Load Bearing Capacity

When selecting fiberglass grating, it’s essential to consider the load-bearing capacity to ensure it can handle the expected weight.

Panel Sizes and Thickness

Fiberglass grating comes in various panel sizes and thicknesses, allowing for customization based on the specific needs of the project.

Surface Options

Different surface options, such as grit top or concave, provide varying levels of slip resistance and safety, suitable for different applications.

Fiberglass Grating Installation

Preparation and Planning

Proper preparation and planning are crucial for a successful installation. This includes measuring the area, selecting the right grating type, and ensuring all materials and tools are on hand.

Tools and Equipment Needed

Basic tools required for installation include measuring tape, saws, clamps, and personal protective equipment.

Step-by-Step Installation Guide

- Measure the Area: Ensure accurate measurements of the installation area.

- Cut the Grating: Use a saw to cut the grating to the required size.

- Position the Grating: Place the grating panels in the designated area.

- Secure the Grating: Use clamps and fasteners to secure the grating in place.

- Inspect the Installation: Ensure the grating is firmly installed and check for any loose sections.

Safety Precautions When Working with Fiberglass

Protective Gear

Always wear protective gear, including gloves, safety glasses, and masks, to prevent exposure to fiberglass particles.

Handling and Cutting Safety

When cutting fiberglass, use appropriate tools and work in a well-ventilated area to minimize dust and particle inhalation.

Disposal of Waste

Dispose of fiberglass waste according to local regulations to minimize environmental impact.

Maintenance and Care for Fiberglass Grating

Regular Cleaning

Regular cleaning with water and mild detergent helps maintain the grating’s appearance and functionality.

Inspection and Repairs

Conduct regular inspections to identify any damage or wear and perform necessary repairs to extend the grating’s lifespan.

Preventive Measures

Implement preventive measures, such as applying protective coatings, to enhance the durability and longevity of fiberglass grating.

Cost Analysis of Fiberglass Grating

Initial Costs

While the initial cost of fiberglass grating may be higher than traditional materials, its long-term benefits often justify the investment.

Long-term Value

The durability and low maintenance requirements of fiberglass grating contribute to its long-term value, making it a cost-effective choice over time.

Comparison with Other Materials

When comparing costs, consider the lifespan, maintenance, and replacement frequency of fiberglass grating versus traditional materials.

Environmental Impact of Fiberglass Grating

Sustainability

Fiberglass grating is a sustainable choice due to its long lifespan and low maintenance requirements, reducing the need for frequent replacements.

Recycling and Disposal

While fiberglass recycling options are limited, ongoing research is exploring ways to recycle and repurpose fiberglass materials.

Eco-Friendly Alternatives

Advancements in eco-friendly resins and production methods are making fiberglass grating an even more sustainable option.

Fiberglass Grating in Harsh Environments

Chemical Resistance

Fiberglass grating is resistant to a wide range of chemicals, making it suitable for use in chemical processing plants and other harsh environments.

UV Stability

UV-resistant resins used in fiberglass grating ensure it remains stable and durable even when exposed to direct sunlight.

Thermal Resistance

Fiberglass grating can withstand extreme temperatures, making it suitable for use in high-heat environments.

Innovations in Fiberglass Grating

Technological Advances

Innovations in resin formulations and manufacturing processes are enhancing the performance and durability of fiberglass grating.

New Applications

Emerging applications, such as in renewable energy and advanced construction techniques, are expanding the use of fiberglass grating.

Future Trends

Future trends in fiberglass grating include the development of more sustainable materials and improved production efficiency.

Regulations and Standards for Fiberglass Grating

Industry Standards

Fiberglass grating must meet industry standards, such as those set by ASTM and ISO, to ensure quality and safety.

Compliance Requirements

Compliance with regulations ensures that fiberglass grating installations are safe and effective, meeting the necessary performance criteria.

Quality Assurance

Quality assurance processes, including testing and certification, are essential to ensure the reliability and safety of fiberglass grating.

Conclusion

Fiberglass grating is a highly versatile and durable material with a wide range of applications across various industries. Its advantages, including corrosion resistance, lightweight properties, and high strength, make it a preferred choice over traditional materials. By understanding its properties, installation methods, and maintenance requirements, users can ensure the optimal performance and longevity of fiberglass grating.