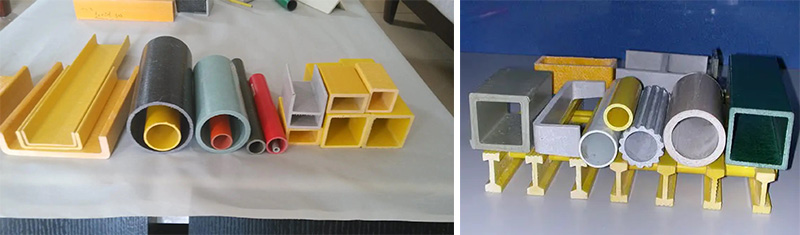

The pultrusion process is special in the FRP forming process, which is suitable for the production of FRP profiles with various cross-sectional shapes, such as rods, tubes, and solid profiles (I-shaped, grooved, square profiles), and hollow profiles.

Advantages of FRP pultrusion profiles:

- The production process is continuous, the product quality is stable, and the repeatability is good;

- The content of reinforcing material can be adjusted according to requirements, and the product has high strength;

- It can adjust the longitudinal strength and transverse strength of the product to meet different usage requirements;

- It can produce products with complex cross-sectional shapes to meet the requirements of special occasions;

- The product has good integrity, and the utilization rate of raw materials is high;

- The investment cost of equipment is low.

At present, many pultruded products have formed series, such as groove type, angle type, I-shaped type, square tube, rectangular tube, round tube, round bar, etc., but the specifications and dimensions of various manufacturers, especially the mechanical performance indicators, vary between manufacturers It is relatively large, causing inconvenience for users in design and use. It is easier for inferior products to be mixed into the market, resulting in quality accidents and adverse effects.

Unicomposite is committed to providing overall solutions for FRP in industrial buildings, marine engineering, underwater engineering, fence systems, large-scale operation platforms, from design, manufacturing to construction, and adhering to the concept of “not for profit or loss, only for inheritance”, only Make qualified products, pursue quality, just for better!