Introduction

In modern construction, the choice of materials plays a crucial role in determining the durability, safety, and efficiency of a structure. One material that has steadily gained popularity is Fiber Reinforced Polymer (FRP), known for its exceptional strength-to-weight ratio and resistance to environmental stressors. Among the various FRP components available, the FRP outside angle has emerged as a pivotal element in providing structural reinforcement, particularly in environments where traditional materials may fail.

This article will explore the key benefits and applications of FRP outside angles, highlighting why they are becoming the go-to solution for builders and engineers across various industries. Whether you’re involved in commercial construction, marine projects, or industrial installations, understanding the role of FRP outside angles could significantly improve the longevity and performance of your structures.

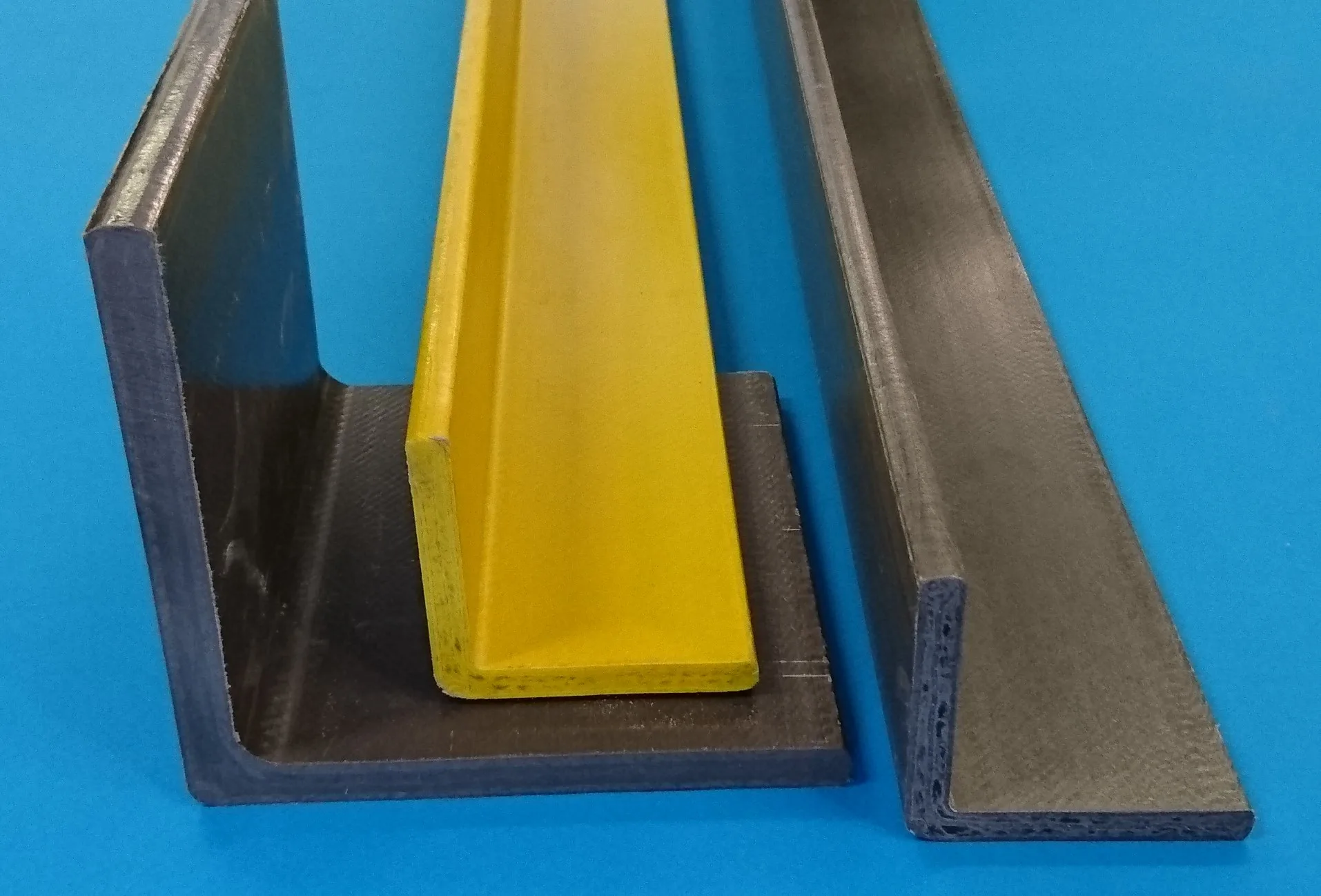

frp outside angle

What is an FRP Outside Angle?

An FRP outside angle is a structural element used to reinforce the outer edges and corners of constructions, such as walls, columns, and frames. These angles are made from Fiber Reinforced Polymer, a composite material that combines the strength of fiber reinforcements (like glass, carbon, or aramid) with a polymer matrix. The result is a material that is both lightweight and incredibly durable.

FRP outside angles serve several important purposes: they protect external corners from wear and tear, provide additional support for structural elements, and prevent damage from environmental factors. Thanks to their unique properties, these angles are used in a variety of industries, including construction, marine, and infrastructure projects. The growing use of FRP outside angles is driven by their resistance to corrosion, lightweight nature, and ability to withstand high stress without cracking or breaking.

Key Benefits of FRP Outside Angles

- Durability and Longevity

FRP materials are well known for their incredible durability, especially when compared to traditional construction materials like steel or aluminum. FRP outside angles are resistant to corrosion, making them ideal for environments that are exposed to moisture, chemicals, or saltwater. This longevity ensures that structures reinforced with FRP components maintain their integrity over time, reducing the need for frequent repairs or replacements. - Corrosion Resistance

One of the biggest advantages of FRP materials, including FRP outside angles, is their resistance to corrosion. This makes them particularly valuable in environments that are harsh or exposed to the elements. For example, structures located near coastal areas or industrial settings where exposure to chemicals is common will greatly benefit from using FRP outside angles. Unlike metal components, which can rust and degrade, FRP remains stable, extending the lifespan of the structure. - Lightweight and Easy to Install

Despite being incredibly strong, FRP outside angles are lightweight, which makes transportation and installation much easier compared to heavier materials like steel. This ease of installation translates to lower labor costs, quicker project completion, and fewer logistical challenges on-site. Contractors find FRP components to be easier to handle, reducing the need for specialized equipment. - Low Maintenance Costs

Thanks to their corrosion resistance and durability, FRP outside angles require minimal maintenance over time. Traditional materials such as wood, steel, and aluminum need regular upkeep to maintain their functionality, but FRP angles hold up better in the long run. This reduces both the time and money spent on maintenance, making them a cost-effective solution for long-term projects. - Design Flexibility

FRP outside angles are highly customizable. They can be manufactured to fit specific dimensions and designed to meet particular project requirements. This flexibility makes them a popular choice for architects and engineers who need materials that can accommodate unique construction challenges or design needs.

Applications of FRP Outside Angles in Construction

- Commercial Buildings

In commercial construction, FRP outside angles are frequently used to reinforce exterior structures, such as facades, walls, and roofing systems. These angles add structural support to external corners, where stress and wear are often higher. FRP angles also provide excellent protection against weathering and environmental degradation, which is critical for maintaining the aesthetic and functional integrity of commercial properties. - Industrial Settings

Factories, warehouses, and other industrial facilities often deal with harsh environments, where exposure to chemicals, moisture, and extreme temperatures is common. FRP outside angles are ideal for these settings due to their resistance to corrosion and ability to withstand high stress. They help maintain the structural integrity of industrial buildings by reinforcing corners and edges prone to damage. - Marine and Coastal Infrastructure

One of the most significant challenges in marine construction is dealing with the corrosive effects of saltwater. FRP outside angles are widely used in marine projects, such as piers, docks, and coastal facilities, because they are not susceptible to rust like metal components. Their ability to endure prolonged exposure to saltwater and moisture makes them an invaluable material for marine and coastal applications. - Transportation Projects

In transportation infrastructure projects, such as bridges, roads, and tunnels, FRP outside angles provide critical support to ensure the stability and longevity of the structure. FRP’s lightweight yet strong properties make it an ideal choice for reinforcing structural components in high-stress areas. Its resistance to environmental degradation also makes it an excellent option for outdoor transportation infrastructure that is constantly exposed to the elements.

Installation and Best Practices

Installing FRP outside angles involves a straightforward process, though ensuring proper alignment and secure installation is crucial for long-term performance. These angles are typically attached to structural corners using adhesives, fasteners, or a combination of both. It’s important to select the appropriate bonding materials based on the specific environment and load requirements of the project.

To achieve the best results, follow these installation tips:

- Ensure surfaces are clean and free of debris before attaching the FRP angles.

- Use compatible adhesives that can withstand the specific environmental conditions.

- Check that the angles are properly aligned and securely fastened to avoid any misalignment that could affect structural integrity.

- Periodically inspect the installation over time to confirm that the angles remain stable and undamaged.

By following these best practices, you can ensure that your FRP outside angles will provide the necessary support and protection for the structure.

Conclusion

FRP outside angles have become an essential component in modern construction due to their unmatched combination of durability, corrosion resistance, and flexibility. Whether in commercial, industrial, marine, or transportation projects, these angles provide crucial structural support that extends the lifespan of buildings and infrastructure. Additionally, their lightweight nature and ease of installation make them a cost-effective solution for a wide range of construction needs.

As the demand for sustainable and long-lasting building materials continues to grow, FRP outside angles offer a smart, future-proof solution for builders and engineers. If you’re planning a construction or renovation project, consider incorporating FRP outside angles to ensure your structure stands the test of time.