Introduction to FRP Fiberglass Grating

What is FRP Fiberglass Grating?

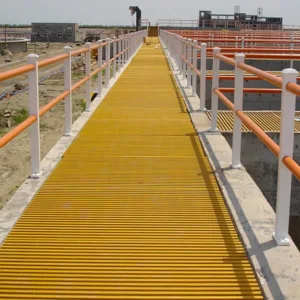

Fiberglass Reinforced Plastic (FRP) grating is a composite material made from fiberglass reinforcements and a resin matrix, offering an alternative to traditional metal gratings. It provides exceptional strength, durability, and corrosion resistance, making it a preferred choice in harsh environments.

frp fiberglass grating

History and Development

The development of FRP grating began in the mid-20th century as industries sought materials that could withstand corrosive elements without the weight and maintenance issues of metal. Over the decades, advancements in composite technology have significantly enhanced its performance and applications.

Components and Materials Used

FRP grating typically consists of a resin system (such as polyester or vinyl ester) combined with fiberglass strands that are interwoven and bonded to form a robust structure. The selection of resin and fiber types can be tailored to meet specific environmental and mechanical requirements.

Types of FRP Grating

Molded FRP Grating

Molded FRP grating is created by placing continuous fiberglass strands in a mold, which is then filled with resin to form a solid, one-piece panel. This type is known for its uniform construction and excellent load-bearing capabilities.

Pultruded FRP Grating

Unlike molded grating, pultruded FRP grating involves pulling fiberglass strands through a resin bath and then forming them into shapes through a continuous process. This method allows for greater flexibility in design and typically offers higher structural integrity.

Comparing Molded and Pultruded Gratings

While both types offer significant advantages, the choice between molded and pultruded FRP grating depends on the specific application, load requirements, and environmental conditions. Molded grating is generally more cost-effective and better suited for high-corrosion areas, whereas pultruded grating provides superior strength and stiffness.

Advantages of FRP Grating

Durability and Strength

FRP grating offers exceptional durability and strength-to-weight ratio, outperforming traditional materials like steel in many applications. Its resistance to bending and impact makes it suitable for heavy-duty industrial use.

Corrosion Resistance

One of the primary advantages of FRP grating is its inherent resistance to rust, corrosion, and chemical attack, which extends its lifespan and reduces maintenance costs, especially in chemically aggressive environments.

Lightweight and Ease of Installation

Weighing significantly less than steel, FRP grating is easier to transport and install, often requiring less structural support and reducing overall project costs. Its lightweight nature also makes it ideal for installations where weight is a critical factor, such as on offshore platforms or elevated walkways.

Applications of FRP Grating

Industrial Applications

FRP grating is extensively used in various industrial settings, including chemical plants, water treatment facilities, and oil and gas operations, where safety and durability are paramount.

Public Infrastructure

Municipalities increasingly turn to FRP grating for public infrastructure projects such as bridges, walkways, and drain covers due to its longevity and minimal maintenance requirements.

Other Commercial Uses

Beyond industrial and public applications, FRP grating is also found in commercial settings such as recreational areas, marinas, and sports facilities, offering safety, aesthetic appeal, and resistance to environmental elements.

Installation Process

Pre-Installation Planning

Effective installation of FRP grating starts with thorough planning. This includes assessing the site conditions, determining the appropriate type of grating, and preparing the necessary tools and equipment.

Step-by-Step Installation Guide

Installation typically involves measuring and cutting the grating to fit the designated area, securing it with specialized fasteners and clips, and ensuring all pieces are properly aligned and secured.

Safety Considerations During Installation

Safety is paramount when installing FRP grating. Installers should wear appropriate personal protective equipment (PPE) and follow best practices to prevent accidents and ensure a successful installation.

Maintenance and Care

Routine Maintenance Tips

FRP grating requires minimal maintenance, but regular inspections and cleaning can help extend its lifespan and maintain its appearance. Simple procedures like removing debris and occasional washing with mild detergents are generally sufficient.

Repair and Replacement

Although FRP grating is designed for durability, it may require repair or replacement if damaged. Techniques such as patching or replacing sections can be performed with basic tools and materials.

Longevity and Lifecycle Management

With proper care, FRP grating can last for many years without significant degradation, even in harsh environments. Lifecycle management involves regular assessments to ensure the grating continues to meet safety and performance standards.

Comparative Analysis

FRP vs. Steel Grating

Compared to steel, FRP grating offers superior corrosion resistance, reduced weight, and easier handling, though it may have a higher initial cost. However, the long-term savings in maintenance and replacement often justify the investment.

FRP vs. Aluminum Grating

While aluminum also resists corrosion, FRP grating typically provides better performance in terms of strength and thermal resistance, making it a better choice for more demanding applications.

Cost-Benefit Analysis

A detailed cost-benefit analysis can help stakeholders understand the long-term advantages of FRP grating over traditional materials, factoring in durability, maintenance costs, and performance under various environmental conditions.

Innovations in FRP Grating

Recent Technological Advancements

Recent innovations in FRP grating include the development of new resin formulations and manufacturing techniques that enhance its mechanical properties and environmental resistance.

Future Trends in FRP Materials

The future of FRP materials looks promising with ongoing research focused on enhancing sustainability, reducing costs, and improving performance characteristics, which could open new markets and applications.

Sustainability and Environmental Impact

FRP grating is gaining recognition for its environmental benefits, including recyclability and reduced environmental impact compared to metals, which require high energy inputs for production and maintenance.

Choosing the Right FRP Grating

Factors to Consider

Selecting the right FRP grating involves considering load requirements, environmental conditions, and specific application needs. Understanding these factors can guide the choice of the type, size, and finish of grating.

Customization and Design Options

FRP grating can be customized in terms of color, surface texture, and material composition to meet specific requirements, enhancing both functional and aesthetic aspects of a project.

Vendor Selection and Quality Assurance

Choosing a reputable vendor is crucial for ensuring high-quality FRP grating. It’s important to consider the vendor’s track record, manufacturing standards, and commitment to customer service.

Case Studies

Successful Implementation in Industries

Case studies highlight successful implementations of FRP grating in various industries, demonstrating its effectiveness in overcoming challenges such as corrosion, load-bearing capacity, and installation complexity.

Challenges Overcome with FRP Grating

Examples of challenges overcome with the use of FRP grating can help potential users anticipate and address similar issues in their projects.

Comparative Success Stories

Comparative case studies provide insights into how FRP grating has outperformed other materials in similar applications, offering valuable lessons and best practices.

Conclusion

Summary of Benefits

FRP fiberglass grating offers numerous benefits including superior corrosion resistance, strength, and versatility across a range of applications. Its adaptability and durability make it an excellent choice for many industrial and commercial projects.

Recommendations for Prospective Users

For those considering FRP grating, it is recommended to thoroughly assess the specific needs of the project and choose a reputable vendor who can provide high-quality materials and support throughout the selection and installation process, like Unicomposite.