Fiberglass Stake

Fiber-reinforced polymer (FRP) composite material refers to glass fiber and its products as the reinforcement material and matrix material, through a certain molding process of a composite material. The fibres are glass (in fiberglass). The polymer is polyester thermosetting plastic.FRP is commonly used in aerospace, automotive, chemical, Marine, automotive, transportation and construction industries. They are also commonly found in the electrical industry and communications factories.

what are the advantages of a fiberglass post with coated gravel?

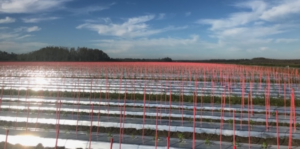

Fiberglass Stake with Coated Grit that will hold up years longer than a traditional wooden stake, especifically for crops grown on the twine with a formulated resin grit coating, UV resistant, fire-retardant .

- Corrosion-Resistance

FRP has excellent electrical insulation property and is a advanced electrical insulation material. It is also used for thermal insulation and fire shield material, and is a material with strong corrosion resistance,Energy saving and environmental protection, acid and alkali resistance.

- Grit Coating

The grit in coating must be of a certain size in order to hold the twine that keeps the plant standing erect. The presence of sand gives the FRP stake a rough surface, making it easier for plants to climb, Grit size is more than adequate to hold the stake twine under full production loads.

- UV Protection

FRP stakes have a UV Protection Additive that contributes to the extremely long field life cycle. Maximize “Cost vs Benefit” for the Commercial Grower.

- Light weight and high strength

FRP stakes is Light weight and high strength, Flex to bend during bad weather and high winds while under a full production weight load without breaking and they have zero flex memory built into them, And it will not rot or mold.

- Other Advantages

No leaching means our stakes can be used for your Organic Crops;

Up to 3x the life expectancy over wood stakes;

Cost Saving, etc.