Both fiberglass and carbon fiber are inorganic non-metallic materials in new materials and can be used as reinforcing materials in composite materials. People often compare these two materials. Today, Unicomposite will take you to analyze the advantages and disadvantages of each.

What is fiberglass?

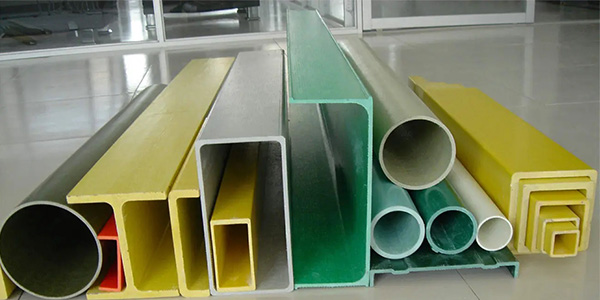

Fiberglass is a kind of inorganic non-metallic material with excellent performance, and there are many kinds. It is manufactured by weaving and other processes, and the diameter of the monofilament is several microns to twenty microns, which is equivalent to 1/20-1/5 of a hair. Consists of thousands of monofilaments. Glass fibers are usually used as reinforcing materials in composite materials, electrical insulating materials and thermal insulation materials, circuit substrates, and other fields of the national economy.

What are the advantages of fiberglass materials?

- High tensile strength and small elongation (3%);

- High elastic coefficient, good rigidity;

- The elongation within the elastic limit is large and the tensile strength is high, so the absorption of the impact energy is large;

- Inorganic fiber is not easy to burn, has good insulation, and has good chemical resistance;

- low water absorption;

- Good dimensional stability and heat resistance;

- Good processability can be made into different forms of products such as strands, bundles, felts, and woven fabrics;

- Transparent through light;

- The development of a surface treatment agent with good adhesion to resin was completed;

- Inexpensive and mass-produced.

What are the disadvantages of fiberglass materials?

- Compared with carbon fiber, fiberglass has an advantage in price, but the performance of carbon fiber material is much superior;

- In terms of tensile strength, fiberglass materials are not as good as carbon fiber materials.

- The fiberglass material is brittle and has poor wear resistance;

- High wave transmittance and poor electromagnetic shielding performance.

What are the application areas of fiberglass?

- For 3d printing technology.

- It is used in the production of glass fiber for electrical insulation and is also widely used in the production of glass fiber for glass fiber-reinforced plastics.

- Used in the production of fiberglass surface mats, etc., and also used to strengthen asphalt roofing materials.

- For military, space, bulletproof armor, and sports equipment.

- A new type of green and environment-friendly reinforcing material used in high-performance reinforced (cement) concrete.

- It is used for the development of underground pipelines, storage tanks, etc.

What is carbon fiber?

Carbon fiber is a high-strength, high-modulus fiber with a carbon content of more than 90%. It can be made of polyacrylonitrile, viscose fiber, pitch fiber, and other raw materials, and is made by high-temperature oxidation and carbonization. It can be mixed with metals, ceramics, resins, and other matrices to make carbon fiber composite materials, which are widely used. The specific gravity of carbon fiber is generally 1.70 g/cm3 to 1.80 g/cm3, the strength is 1200 MPa to 7000 MPa, the elastic modulus is 200 GPa to 400 GPa, and the thermal expansion coefficient is close to zero, even negative (~1.5 × 10 of -6 power).

What are the advantages of carbon fiber materials?

- Carbon fiber material has a small specific gravity, high specific strength, and specific modulus;

- Ultra-high temperature resistance in a non-oxidizing environment, good fatigue resistance, specific heat, and electrical conductivity between non-metal and metal;

- No creep due to temperature difference or long-term operation, small elongation coefficient (1.6%), small thermal expansion coefficient, and anisotropy;

- Good X-ray permeability, good electrical and thermal conductivity, good electromagnetic shielding, etc.

- Strong design ability, the mechanical properties of carbon fiber products can be changed by changing the layup angle or quantity;

- Compared with glass fiber, carbon fiber has more than 3 times Young’s modulus; compared with Kevlar fiber, it’s Young’s modulus is about 2 times;

- Good corrosion resistance, no swelling or swelling in organic solvents, acids, and alkalis, and outstanding corrosion resistance.

What are the disadvantages of carbon fiber materials?

- Carbon fiber products are customized products with high directivity, and because the raw materials and production costs of carbon fiber are particularly high, it is difficult to achieve mass production of carbon fiber products, and there is no price advantage;

- Although carbon fiber composite materials have high tensile strength and weak shear strength, complex stress calculations are required during processing;

- Carbon fiber is a brittle material. It will not deform when subjected to excessive force but will break directly. Therefore, carbon fiber products cannot be repaired and can only be replaced after damage;

- At present, thermosetting carbon fiber composite materials are widely used, which are difficult to recycle and have a poor recycling rate.

What are the application areas of carbon fiber?

- Carbon fiber is traditionally used in addition to thermal insulation. Most of them are added to resins, metals, ceramics, concrete and other materials as reinforcing materials to form composite materials. Carbon fiber has become the most important reinforcement material for advanced composite materials.

- Civil construction field: carbon fiber is also used in the reinforcement and reinforcement of industrial and civil buildings, railway highway bridges, tunnels, chimneys, tower structures, etc. In railway construction, large roof systems and sound insulation walls will have good applications in the future , these will also be very promising application aspects of carbon fiber.

- Carbon fiber is an indispensable strategic basic material for cutting-edge weapons and equipment such as rockets, satellites, missiles, fighter jets and ships. The application of carbon fiber composite materials on the missile body and engine casing of strategic missiles can greatly reduce the weight and improve the missile’s range and assault ability. For example, the three-stage shells of intercontinental missiles developed in the 1980s by the United States are all made of carbon fiber and epoxy resin composite. Material.

- It is widely used in the interior and exterior decoration of automobiles. As an automotive material, the biggest advantage of carbon fiber is its light weight and high strength. Its weight is only 20% to 30% of that of steel, but its hardness is more than 10 times that of steel.

- Carbon fiber is used in the field of sports and leisure, such as clubs, fishing rods, tennis rackets, badminton rackets, bicycles, ski poles, snowboards, windsurfing masts, sailing hulls and other sports products are one of the main users of carbon fiber. Carbon fiber is used in daily necessities, such as audio, Yuba, heaters and other household appliances, as well as mobile phones, notebook computers and other electronic products.

Generally speaking, carbon fiber composite materials have more performance advantages than fiberglass composite materials, but it does not mean that fiberglass materials are useless. First of all, fiberglass materials have advantages in price, and they can be replaced by the two, and the technical requirements are not very high. In the field, the first consideration may be fiberglass materials. Fiberglass material has good insulation performance, non-conductivity, good wave transmittance, and carbon fiber composite material has good conductivity and good electromagnetic shielding. What material should be used should be decided according to your own technical requirements and budget.