There are different technology to produce fiberglass products, pultrusion, pulwinding, filament winding, SMC/BMC and hand lay-up. Most of Unicomposite composite products are pultruded profiles, today we’ll introduce hand lay-up products.

Process:

Brushing or spraying the release agent on the surface of mould evenly.

When the release agent dry, make it coated with a layer of gel coat resin.

For gel coat layer of the gel, put in the upper mold reinforcing material or female mold(surface mat, chopped strand

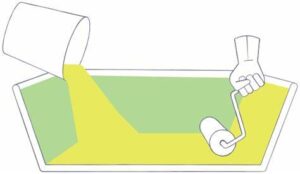

Mat, woven roving etc.), roller and brush coating mixed with resin curing agent, the resin impregnated reinforced materials and keep the bubble, compaction layer laminated, and repeat that operation until it reaches the designed wall thickness.

When we need to choose fiberglass hand lay-up products?

It’s suitable for low volume production.

Products can be cured in room temperature, less equipment investment, low mold depreciation.

Large products and complex shape product can be achieved.

The resin and the reinforced material can be combined freely, and easy to design mixed materials.

The reinforcing rib can be used locally enhanced and can be embedded into the metal piece.

The obtained surface with free color and luster for gel coat layer (such as open molding isone side not smooth).

The fiberglass content is higher than that of injection molding.

But hand lay-up belongs to labour intensive production, product quality is decided by the degree of skilled workers. And property only stick mold surface smooth, the other side is not smooth. So we should choose the most suitable process according to products requirement.

Typical handlay-up products application:

Boat, wind turbine blades,recreation equipment, cooling tower shell, building template. planter, table and chairs.