Fiberglass grating solves the problem of metal corrosion. Why do you say that? Because the advent of fiberglass grating solves the problem of corrosion of steel structural parts. Now FRP has replaced steel with its high strength, lightweight and corrosion resistance, and has jumped into the field of building load-bearing structures.

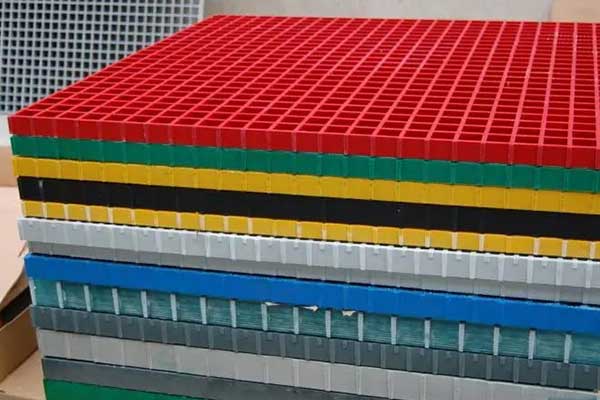

Fiberglass grating in various colors

In the process of chemical production, it is often exposed to strong corrosive media such as acid, alkali, salt, organic solvent, etc., so corrosion and chemical production are always accompanied. For example, nitric acid, ammonium nitrate, and urea workshops in chemical fertilizer production; workshops, floors, trestle bridges, platforms, and underground structures in wet electrolysis workshops in non-ferrous metallurgy production. Due to the volatilization of acid mist, flying dust, running and dripping, deliquescence, and other reasons, the building is seriously corroded, and the steel structure is corroded within a year, it is difficult to bear the load and must be replaced.

In addition, fiberglass grating has the advantages of high strength, lightweight, toughness, corrosion resistance, insulation, and heat insulation, and does not need to be heated during installation, and no sparks will be generated due to collision during use, which is particularly important for chemical production.

Chemical plant fiberglass grating use case

Fiberglass grating can be used as a double-layer ground in the chemical industry. The concept of the solid ground is different from the double-layer grid ground, that is, the upper layer is composed of FRP grids, and the lower layer is the building base floor. The operator walks on the grid surface layer, producing The finished product that can be placed on the surface of the grid, and the waste liquid and waste residue can be discharged to the ground of the lower base. After the operation, it can be washed with a powerful water sprayer to remove the sundries on the ground, which is convenient for operators and managers, checking work.

Fiberglass grating is used to make the plank road in the chemical industry, which is not afraid of corrosion and does not require corrosion coating. There are a large number of operating platforms in chemical plants. The paving materials of these platforms are more reasonable with fiberglass grating, which is corrosion-resistant, requires no paint, and no maintenance, long service life, and is lightweight, so the installation is simple. The operating platform directly supported on the equipment is very suitable.

In addition, fiberglass grating can also play a role in the following occasions:

- Fiberglass grating trench cover, used in parks, squares, or residential areas, can withstand pressure and is anti-skid.

- Fiberglass grating tree grate has the function of protecting trees and beautifying the environment.

- Car wash fiberglass grating, used in the car wash industry, has the advantages of corrosion resistance and long service life.

- Fiberglass stair treads can bear the weight of people, have lower requirements on bearing capacity, and have a certain degree of comfort.

Fiberglass grating solves the problem of metal corrosion, especially in the application of the chemical industry, and solves many problems for the industry. If you are looking for fiberglass grating, please contact us directly.