Introduction to Fiberglass Equal Angles

In today’s industrial and construction landscape, the choice of materials plays a significant role in the durability, functionality, and overall efficiency of projects. One increasingly popular choice is the fiberglass equal angle, a versatile structural component recognized for its strength, resistance to corrosion, and lightweight nature. Unlike traditional materials such as steel or aluminum, fiberglass offers unique properties that make it ideal for a variety of applications, from construction to telecommunications infrastructure.

In this guide, we’ll explore fiberglass equal angles in-depth and compare them to traditional angle materials. By the end, you’ll have a comprehensive understanding of how fiberglass equal angles stand out in terms of composition, benefits, applications, and long-term value, helping you make an informed decision for your next project.

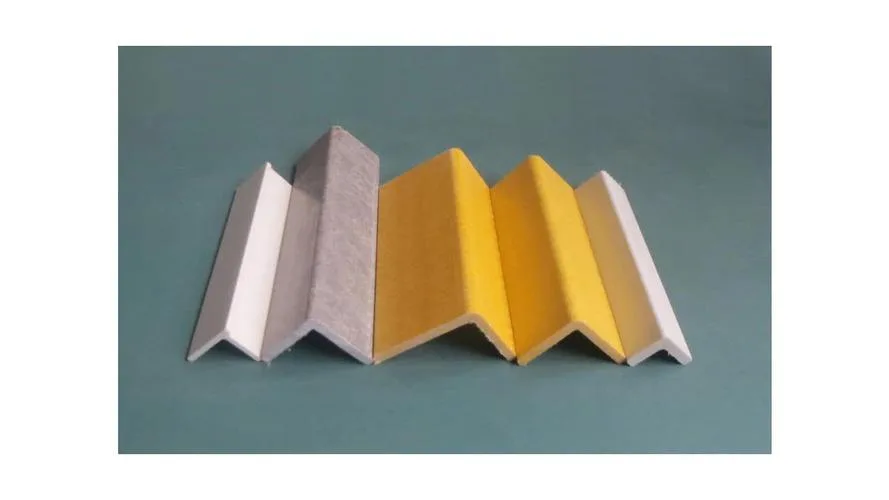

fiberglass equal angle

1. Understanding Fiberglass Equal Angles

What is a Fiberglass Equal Angle?

A fiberglass equal angle is a structural component made from a composite of fiberglass and resins, formed into a right-angle shape where both sides are of equal length. This shape provides structural stability and is commonly used to reinforce structures or support frames. Fiberglass equal angles are especially popular in environments where moisture, chemicals, or other corrosive elements are present, as they are highly resistant to corrosion.

Key Characteristics of Fiberglass Equal Angles

Fiberglass equal angles are characterized by:

- High corrosion resistance: Unaffected by moisture, chemicals, or saltwater, making them ideal for outdoor and industrial settings.

- High strength-to-weight ratio: Despite their low weight, fiberglass angles provide significant structural support.

- Thermal and electrical insulation: Excellent for applications where conductivity is a concern.

How They Differ from Traditional Materials

Compared to metals, fiberglass angles offer distinct advantages in terms of weight, corrosion resistance, and durability. Unlike steel, which can rust, or aluminum, which is susceptible to wear, fiberglass angles require less maintenance over time and are much easier to handle due to their lightweight construction.

2. Composition and Structure

Materials Used in Fiberglass Equal Angles

Fiberglass equal angles are primarily made from glass fibers reinforced with polyester or vinyl ester resins. These materials create a composite that is strong, lightweight, and resistant to environmental stressors. The resins serve as a binding agent, providing additional strength and ensuring durability under various conditions.

Manufacturing Process

The manufacturing process typically involves pultrusion, where fibers are pulled through a resin bath and then shaped and cured to form the angle. This process ensures consistency in quality, structural integrity, and smooth finishes, reducing the risk of cracks or weaknesses in the material.

Variations in Size and Shape

Fiberglass equal angles come in a range of sizes and thicknesses, catering to specific load requirements. This versatility makes them suitable for both large industrial applications and smaller residential projects.

3. Benefits of Fiberglass Equal Angles

Corrosion Resistance

One of the most significant advantages of fiberglass equal angles is their resistance to corrosion. This feature makes them perfect for use in marine, coastal, and high-humidity environments where steel would typically rust over time. Fiberglass equal angles can withstand exposure to saltwater, chemicals, and moisture without compromising structural integrity.

High Strength-to-Weight Ratio

Fiberglass has an exceptional strength-to-weight ratio, making it strong enough to support substantial loads while remaining lightweight. This characteristic is invaluable in projects where reducing the weight of structural components is crucial, such as in bridges, roofing, and decking.

Durability and Longevity

Fiberglass equal angles are known for their durability. They can withstand both mechanical stress and environmental factors without deteriorating, which extends their lifespan and minimizes the need for replacements, providing excellent long-term value.

Electrical and Thermal Insulation Properties

Fiberglass is a natural insulator, which makes fiberglass equal angles ideal for electrical infrastructure and telecommunication projects. Unlike metals, fiberglass doesn’t conduct electricity, making it a safer choice in applications where conductivity would be hazardous.

4. Comparing Fiberglass to Traditional Materials

Common Alternatives (Steel, Aluminum)

In traditional construction, steel and aluminum are the most common materials for equal angles. Steel offers high tensile strength but is heavy and prone to rust. Aluminum, while lighter than steel, is also more susceptible to wear and can be costly in high-stress environments due to its need for reinforcement.

Key Differences in Weight, Cost, and Maintenance

- Weight: Fiberglass is significantly lighter than steel, making it easier to install and handle.

- Cost: While the initial cost of fiberglass may be higher than some metals, the reduced maintenance and replacement needs often result in long-term savings.

- Maintenance: Fiberglass angles require minimal maintenance compared to metals, which often need anti-corrosive coatings or regular replacements.

Environmental Impact of Each Material

Fiberglass is also a more environmentally sustainable option. Unlike metals that require mining and are energy-intensive to produce, fiberglass manufacturing has a smaller carbon footprint and offers a longer lifecycle, reducing the need for frequent replacements.

5. Applications of Fiberglass Equal Angles

Industrial Uses (Construction, Manufacturing)

Fiberglass equal angles are commonly used in industrial construction and manufacturing. Their corrosion-resistant properties make them a great fit for chemical processing plants, factories, and other industrial environments where metals might degrade over time.

Marine and Coastal Structures

In marine environments, where exposure to saltwater is inevitable, fiberglass equal angles provide a long-lasting solution for dock structures, boat supports, and coastal construction. They do not rust and require minimal upkeep, making them ideal for waterfront installations.

Telecommunications and Electrical Infrastructure

The non-conductive properties of fiberglass make it an excellent choice for telecommunication towers, electrical substations, and power lines. In these applications, fiberglass provides structural support without risking electrical conductivity.

Residential and Commercial Building Applications

From roofing support beams to window frames, fiberglass equal angles can be used in both residential and commercial settings, offering strength without adding significant weight to the structure.

6. Installation and Handling Tips

Best Practices for Cutting and Drilling Fiberglass Angles

For optimal results, use carbide-tipped tools when cutting or drilling fiberglass angles. This ensures cleaner cuts and reduces the risk of damaging the material.

Safety Measures for Handling

Fiberglass can create dust during handling, so wearing protective gear like gloves, goggles, and masks is essential to prevent skin irritation and respiratory issues.

Installation Tips for Stability and Performance

Ensure the structure is appropriately secured to prevent movement and ensure long-lasting stability. Using compatible adhesives or bolts specifically designed for fiberglass can enhance stability and reduce maintenance needs.

7. Cost Comparison and ROI

Upfront Costs vs. Long-Term Savings

While fiberglass equal angles may have a higher upfront cost than traditional metal options, the long-term savings from reduced maintenance and longevity often offset this initial investment.

Maintenance and Replacement Factors

Fiberglass equal angles require less frequent maintenance and offer a longer lifespan compared to steel or aluminum, resulting in fewer replacements over time and reducing lifecycle costs.

Calculating ROI for Different Projects

When calculating ROI, consider the cost of installation, maintenance, and replacement over time. Fiberglass typically offers a better ROI in applications where exposure to harsh environmental conditions would otherwise shorten the lifespan of steel or aluminum.

8. Case Studies and Success Stories

Example 1: Industrial Construction

In chemical plants, fiberglass equal angles have been used to construct support frameworks that can withstand corrosive environments, significantly reducing maintenance costs over time.

Example 2: Coastal Infrastructure

Fiberglass equal angles have proven invaluable in dock construction for coastal areas, offering a long-lasting alternative to metals that might otherwise corrode within months of installation.

Example 3: Telecommunications Project

Telecommunications companies have adopted fiberglass equal angles for their tower constructions, benefiting from their non-conductive properties and high durability in all-weather conditions.

9. Frequently Asked Questions

- Why choose fiberglass equal angles over steel or aluminum?

Fiberglass angles are corrosion-resistant, lightweight, and durable, making them a versatile choice for many environments where metals may degrade. - Are fiberglass equal angles suitable for outdoor use?

Yes, they are resistant to moisture, UV rays, and environmental stressors, making them ideal for outdoor use. - What are the weight limitations?

Fiberglass angles offer a high strength-to-weight ratio, supporting significant loads relative to their weight. - Can fiberglass equal angles be customized in size?

Many manufacturers offer custom sizes to fit specific project needs. - How do they hold up under UV exposure?

With UV-resistant coatings, fiberglass angles are well-suited for long-term outdoor use without degradation. - What safety precautions are needed for installation?

Safety gear, including gloves, masks, and goggles, is recommended due to the dust produced when cutting or drilling.

Conclusion

Fiberglass equal angles offer a modern, efficient solution for structural needs, particularly where corrosion resistance, weight savings, and durability are priorities. Compared to traditional materials like steel or aluminum, fiberglass provides excellent long-term value, reducing maintenance costs and environmental impact. For those in construction, manufacturing, or even marine applications, fiberglass equal angles represent a worthwhile investment.