Introduction

In the modern construction world, the demand for strong, durable, and versatile materials has led to the rise of fiberglass-based solutions. One such product gaining popularity is the fiberglass curb angle. Known for its impressive strength and ability to withstand harsh environmental conditions, fiberglass curb angles are now widely used in a variety of industrial and commercial projects.

Whether you’re involved in infrastructure development or industrial construction, understanding the features and benefits of this material is essential. In this article, we’ll explore what fiberglass curb angles are, their key features, the benefits they offer, and how they are applied across different industries.

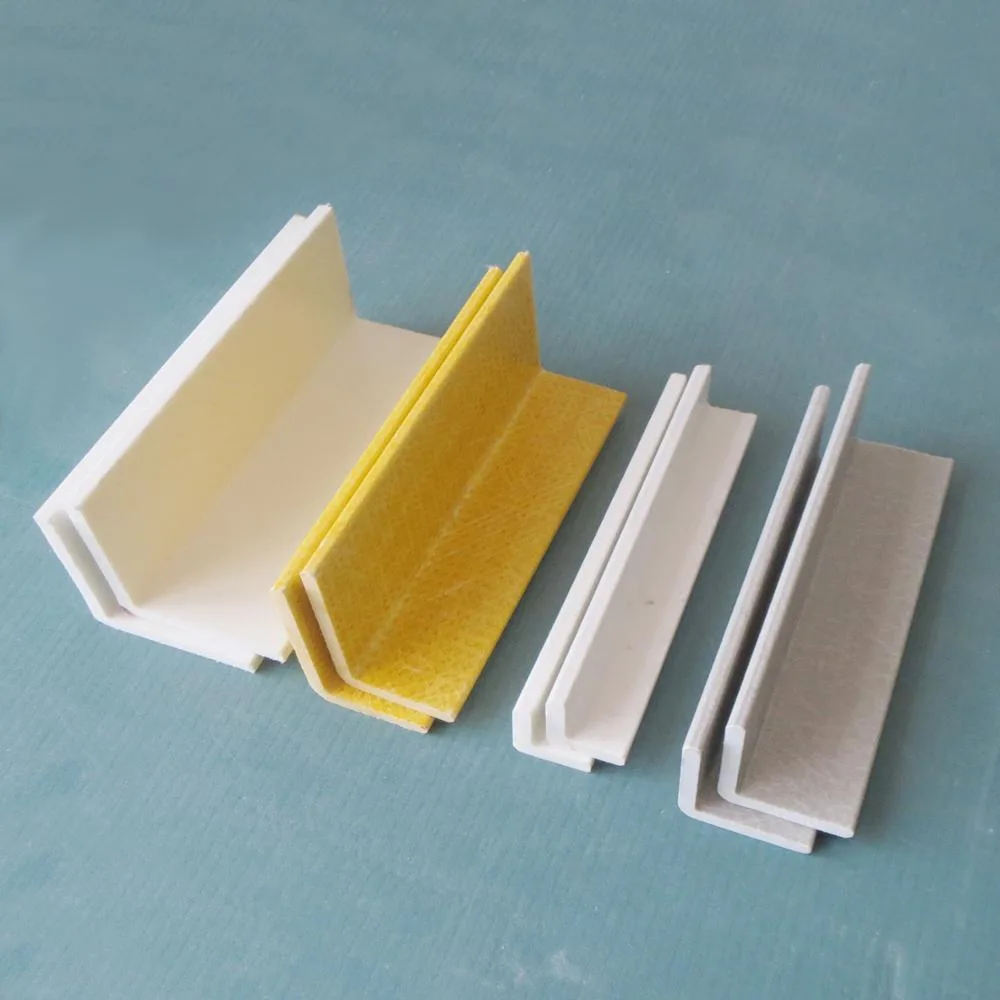

fiberglass curb angle

What is Fiberglass Curb Angle?

A fiberglass curb angle is a structural component used in construction to reinforce and protect the edges of various surfaces, such as concrete curbs, floors, and other building materials. It is made from fiberglass-reinforced plastic (FRP), a composite material known for its excellent strength-to-weight ratio and durability.

Fiberglass curb angles are designed to provide both structural support and protection, ensuring that the edges of surfaces remain intact even under heavy load or environmental stress. Unlike traditional curb angles made from steel or aluminum, fiberglass is non-corrosive and resistant to chemical exposure, making it ideal for use in industrial settings where harsh substances might be present.

Because of their lightweight nature, fiberglass curb angles are easier to transport and install, reducing labor and time costs on job sites. Additionally, fiberglass curb angles can be customized to meet specific project requirements, allowing for flexibility in design and application.

Key Features of Fiberglass Curb Angle

Fiberglass curb angles are known for a variety of features that make them an attractive option for construction projects. Here are some of the most notable characteristics:

- Durability: One of the key strengths of fiberglass curb angles is their durability. They can withstand high-impact forces, making them perfect for areas subject to heavy traffic or wear and tear.

- Corrosion Resistance: Fiberglass is naturally resistant to rust, corrosion, and chemical exposure, unlike metal alternatives. This makes fiberglass curb angles ideal for projects in harsh environments such as chemical plants or coastal areas where saltwater corrosion is a concern.

- Lightweight Design: Despite their strength, fiberglass curb angles are much lighter than steel or aluminum, making transportation and installation much easier and faster. This reduces overall project costs.

- Non-Conductive: Fiberglass is a non-conductive material, meaning it does not conduct electricity. This is particularly important in certain industrial settings where electrical safety is a priority.

- UV Resistance: Fiberglass materials often include UV-resistant coatings, which help curb angles maintain their structural integrity and appearance even when exposed to sunlight over long periods.

These features make fiberglass curb angles a reliable, long-lasting solution for a wide range of construction and industrial applications.

Benefits of Fiberglass Curb Angle in Construction

When it comes to construction, using the right materials can significantly impact the longevity and cost-effectiveness of a project. Fiberglass curb angles offer numerous advantages over more traditional materials:

- Long-Term Durability: Fiberglass curb angles are engineered to last. Their resistance to rust, chemicals, and UV rays ensures they maintain their integrity over time, even in the most demanding environments. This makes them an excellent choice for long-term infrastructure projects.

- Cost Savings: While the initial cost of fiberglass curb angles may be slightly higher than some metal alternatives, the long-term cost savings are substantial. Due to their low maintenance requirements and resistance to environmental degradation, they help reduce repair and replacement costs over time.

- Minimal Maintenance: Unlike steel or aluminum, which may require regular inspections for rust or corrosion, fiberglass curb angles require little to no maintenance once installed. This makes them ideal for projects in remote or hard-to-access locations where maintenance is challenging.

- Enhanced Safety: In industrial settings where safety is paramount, fiberglass curb angles offer an extra layer of protection. Their non-conductive nature means they won’t pose electrical hazards, and their corrosion-resistant properties make them safe to use in chemical-rich environments.

- Sustainability: Fiberglass curb angles are often made from recyclable materials, contributing to a more sustainable construction process. By choosing fiberglass, companies can align with environmental standards and reduce their ecological footprint.

These benefits make fiberglass curb angles a smart investment for contractors looking for long-lasting and cost-effective solutions.

Applications of Fiberglass Curb Angle

The versatility of fiberglass curb angle extends across numerous industries, making it an invaluable component in various projects. Here are some of the most common applications:

- Commercial Construction: In commercial settings, fiberglass curb angles are often used to reinforce and protect the edges of flooring, roofing, and curbing systems. Their ability to withstand heavy foot traffic and equipment makes them ideal for high-traffic areas such as parking lots, warehouses, and loading docks.

- Infrastructure Projects: Fiberglass curb angles are a popular choice for infrastructure projects like roadways, bridges, and tunnels. Their resistance to corrosion makes them suitable for use in environments exposed to the elements, such as coastal or flood-prone areas.

- Industrial Settings: In industries such as chemical processing, oil and gas, and manufacturing, fiberglass curb angles are commonly used to reinforce surfaces exposed to corrosive chemicals or extreme temperatures. Their non-conductive properties also make them a safe choice for areas near electrical equipment.

- Marine Environments: Due to their high resistance to saltwater corrosion, fiberglass curb angles are frequently used in marine construction, including docks, piers, and coastal structures. They provide long-lasting protection against the harsh conditions of marine environments.

Fiberglass curb angles are essential in any setting where durability, resistance to corrosion, and long-term performance are critical factors.

Conclusion and Call to Action

Fiberglass curb angles have proven to be a game-changer in the construction industry. Their unique combination of strength, lightweight design, and resistance to harsh environmental factors makes them the ideal solution for projects requiring reliable edge protection and reinforcement. Whether you are working on a commercial building, industrial site, or infrastructure project, fiberglass curb angles offer a durable, cost-effective option.

If you’re ready to enhance the longevity and quality of your next construction project, consider incorporating fiberglass curb angle into your design. Reach out to a trusted supplier today and discover the benefits of this innovative material firsthand.