Introduction

Fiberglass compression molding is a manufacturing process that is revolutionizing various industries with its efficiency, versatility, and cost-effectiveness. This technique, which involves shaping fiberglass materials under high pressure and heat, is renowned for producing durable and lightweight components that are used in automotive, aerospace, construction, and consumer goods industries. As demand for lightweight yet strong materials continues to grow, understanding the nuances of fiberglass compression molding becomes increasingly essential for manufacturers and engineers alike.

fiberglass compression molding

What is Fiberglass Compression Molding?

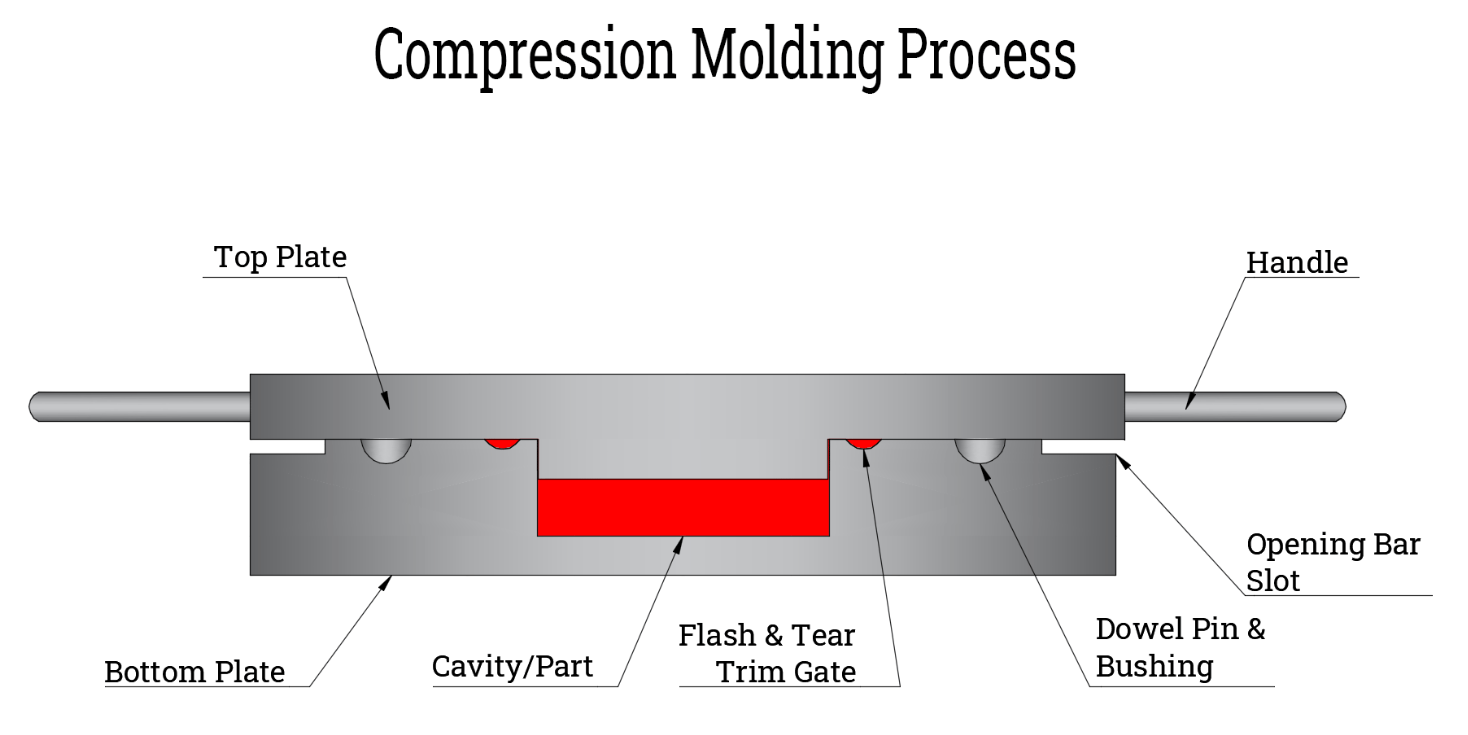

Fiberglass compression molding is a process that involves the use of a heated mold to shape fiberglass materials under high pressure. This method is particularly effective in creating complex shapes and large parts that require both strength and precision. The process begins by placing a fiberglass sheet or a pre-measured amount of fiberglass material into a heated mold. The mold is then closed and pressure is applied, causing the material to conform to the shape of the mold cavity. After cooling, the mold is opened, and the finished part is ejected.

The primary advantage of fiberglass in compression molding lies in its unique properties—lightweight, yet incredibly strong, resistant to corrosion, and capable of withstanding high temperatures. These characteristics make fiberglass an ideal material for applications where durability and reliability are paramount.

Benefits of Fiberglass Compression Molding

- Durability and Strength

Fiberglass compression molded products are known for their exceptional strength-to-weight ratio, making them ideal for applications where both lightweight and durability are required. The material’s resistance to rust, corrosion, and wear extends the lifespan of the components, reducing the need for frequent replacements. - Cost-Effectiveness

The compression molding process is generally faster and less labor-intensive than alternative methods such as injection molding or manual layup. This efficiency translates to lower production costs, making fiberglass compression molding an economically viable option for mass production. - Versatility in Design and Application

Fiberglass compression molding allows for a high degree of flexibility in terms of shape and design. The process can accommodate complex geometries and intricate details, making it suitable for a wide range of applications across multiple industries. - Lightweight Properties

One of the standout benefits of fiberglass compression molding is the lightweight nature of the finished products. This property is particularly advantageous in industries such as automotive and aerospace, where reducing weight is crucial for improving fuel efficiency and performance.

Applications of Fiberglass Compression Molding

Fiberglass compression molding finds applications in several key industries:

- Automotive Industry: Used in the production of body panels, bumpers, and structural components due to its lightweight and strength properties.

- Aerospace: Ideal for manufacturing lightweight parts and components that can withstand high stress and temperature variations.

- Construction: Utilized in creating durable building materials and infrastructure components that require high strength and resistance to environmental factors.

- Consumer Goods: Commonly used in the production of durable household items, outdoor furniture, and sports equipment.

Techniques and Best Practices in Fiberglass Compression Molding

To achieve optimal results in fiberglass compression molding, manufacturers should adhere to certain best practices:

- Control of Temperature and Pressure: Ensuring the mold is heated to the correct temperature and applying consistent pressure are crucial for producing high-quality parts.

- Material Preparation: Proper preparation of the fiberglass material, including cutting to the correct size and shape, is essential to avoid defects.

- Avoiding Common Mistakes: Issues such as incomplete filling of the mold, warping, or surface defects can often be traced back to improper handling or inaccurate measurements. By maintaining strict quality control and regular mold maintenance, these problems can be minimized.

Conclusion

Fiberglass compression molding is a highly effective and versatile manufacturing process that offers numerous benefits, including durability, cost-effectiveness, and design flexibility. Its wide range of applications in industries such as automotive, aerospace, construction, and consumer goods underscores its value as a go-to solution for creating strong, lightweight components. For businesses looking to innovate and optimize their production processes, fiberglass compression molding is a method worth exploring.

For more information on how fiberglass compression molding can benefit your business, or to request a consultation, contact our experts today.