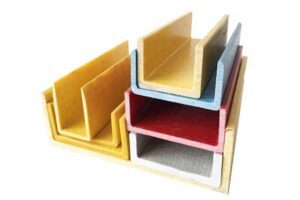

Fiberglass channel (pultruded channel) is made of alkali-free untwisted glass fiber roving, impregnated with polyester resin, continuously pultruded, and heated and cured. Compared with other materials, it has the following obvious advantages:

- Fiberglass channel requires almost no maintenance.

- Fiberglass channel has good tensile strength, bending strength, and impact toughness does not deform, and has excellent chemical stability in the atmosphere, rainwater, and general concentrations of acids, alkalis, salts, and other media.

- Fiberglass channel has good designability and is suitable for various industries and environments.

- Good electrical and thermal insulation, not afraid of lightning strikes, good thermal insulation performance.

- High surface finish, UV resistance, good gloss retention, no discoloration, easy to clean.

Application of Fiberglass Channel

In today’s construction industry, the use of Fiberglass channels is very beneficial to reduce the weight of buildings, improving the use of buildings, reforming architectural design, speeding up construction progress, reducing project costs, and improving economic benefits. It can be used for operating platforms, handrails & Guardrails, brackets, equipment, tool handles, insulating support members, antenna columns, high-voltage cable trays, aisles, switchboards and switch rooms, pressure bars in trains and cars, packing brackets in towers, frame materials, etc.