Introduction

In industrial settings, where safety, durability, and reliability are paramount, the choice of materials can have a significant impact. One material that stands out for use in catwalks and platforms is fiberglass catwalk grating. Fiberglass, known for its corrosion resistance and lightweight properties, has become a preferred alternative to traditional materials like steel and aluminum, especially in environments prone to moisture or harsh chemicals.

Fiberglass catwalk grating offers a solution that is not only sturdy but also cost-effective and easy to maintain. This comprehensive guide will explore the benefits and various applications of fiberglass catwalk grating, highlighting why it’s a smart choice for industries that prioritize safety and efficiency.

fiberglass catwalk grating

What is Fiberglass Catwalk Grating?

Fiberglass catwalk grating is a type of platform or walkway made from fiberglass-reinforced plastic (FRP). The material consists of a resin matrix that is reinforced with glass fibers, creating a product that is incredibly strong yet lightweight. Fiberglass grating is widely used in industrial and commercial settings where there’s a need for reliable walkways, platforms, or covers that can withstand heavy foot traffic, machinery, and harsh environmental conditions.

Unlike traditional materials like steel, which are prone to rust, or aluminum, which can become slippery in wet environments, fiberglass grating offers superior performance. It’s non-corrosive, non-conductive, and resistant to fire, making it a safer and more durable option. Fiberglass grating also offers better slip resistance and requires less maintenance, making it a practical solution for industries that need long-lasting, safe, and economical walkway systems.

Key Benefits of Fiberglass Catwalk Grating

- Durability

Fiberglass catwalk grating is highly resistant to corrosion, which makes it ideal for use in environments exposed to moisture, chemicals, or saltwater. This material doesn’t rust or degrade over time, ensuring a long lifespan even in the toughest industrial settings. Additionally, fiberglass grating is designed to withstand heavy loads, making it a reliable choice for supporting both workers and equipment. - Safety Features

Safety is a top concern in any industrial setting, and fiberglass catwalk grating excels in this area. Its surface is designed to be slip-resistant, even when wet or exposed to oil or other chemicals. This reduces the risk of accidents, providing a safer working environment. Fiberglass grating is also non-conductive, making it suitable for use near electrical equipment, and many fiberglass products are fire-retardant, adding an extra layer of protection. - Low Maintenance

Another advantage of fiberglass catwalk grating is its low maintenance requirements. Unlike metal grating that may require frequent painting or coating to prevent rust, fiberglass grating is virtually maintenance-free. It does not need to be treated with special coatings and can maintain its structural integrity for years with minimal upkeep. This reduces the overall cost of ownership and adds to its long-term value. - Cost-effectiveness

While the upfront cost of fiberglass catwalk grating may be higher than some alternatives, its durability and low maintenance needs make it a more cost-effective choice in the long run. The reduced need for repairs or replacements, combined with a longer lifespan, provides significant savings over time, particularly in industries that experience harsh conditions where traditional materials would degrade more quickly.

Applications of Fiberglass Catwalk Grating

Fiberglass catwalk grating has a wide range of applications across various industries, thanks to its versatility and resilience. Below are some key sectors where fiberglass catwalk grating is commonly used:

- Industrial Settings

In industries like oil and gas, chemical processing, and power generation, fiberglass catwalk grating is the preferred choice for walkways and platforms. These environments often involve exposure to corrosive substances, which makes fiberglass grating an ideal solution. Its ability to resist chemical damage while providing a sturdy surface ensures both safety and durability. - Commercial Uses

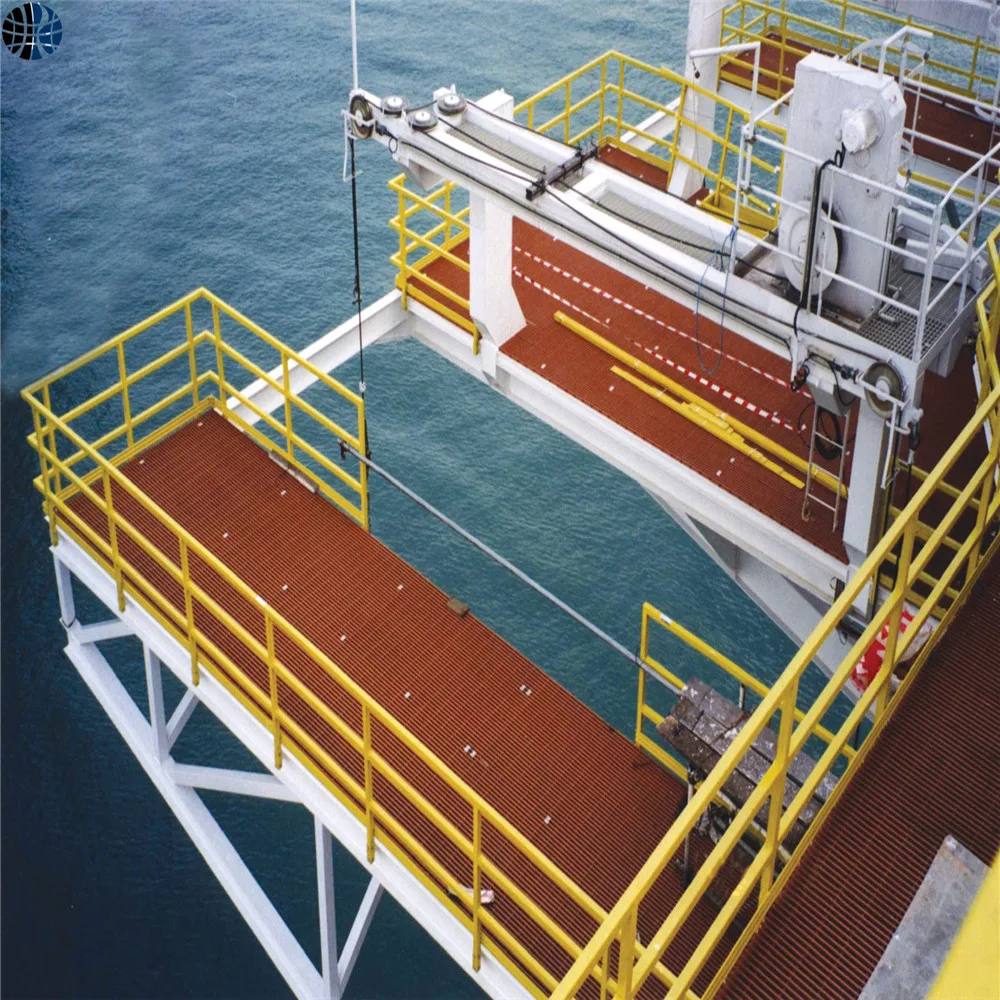

Fiberglass catwalk grating is also gaining popularity in commercial facilities, such as public spaces, sports complexes, and pedestrian walkways. Its non-slip surface, combined with its aesthetic versatility, makes it suitable for these high-traffic areas. It can be customized to match the design of the space, offering both functionality and visual appeal. - Marine and Offshore Platforms

Marine environments present unique challenges, particularly due to constant exposure to moisture and saltwater. Fiberglass catwalk grating is a natural choice for offshore platforms, ship decks, and coastal infrastructure. Its resistance to saltwater corrosion and its lightweight nature make it easy to install in these challenging environments, while ensuring longevity and safety. - Water Treatment and Waste Facilities

Another key application of fiberglass catwalk grating is in water treatment and waste management facilities, where exposure to chemicals and moisture is common. The non-corrosive nature of fiberglass ensures that it performs well in these environments, where traditional materials would likely fail or require frequent replacement.

Installation and Maintenance Tips for Fiberglass Catwalk Grating

Fiberglass catwalk grating is relatively easy to install due to its lightweight properties, making it a favorite among contractors and industrial operators. Here are some best practices to ensure optimal installation and maintenance:

- Installation Tips:

Fiberglass grating can be easily cut and shaped to fit specific dimensions. It’s important to use appropriate tools, such as diamond-tipped blades, for precise cuts. The material should be securely fastened using recommended fiberglass clips or brackets to prevent movement or shifting once installed. - Maintenance Tips:

While fiberglass grating requires little maintenance, regular inspections can help identify any potential issues early. In environments with heavy use or chemical exposure, periodic cleaning with mild detergents can help maintain the grating’s appearance and functionality. However, abrasive cleaning products should be avoided to preserve the integrity of the surface. - Longevity Tips:

To extend the life of fiberglass catwalk grating, ensure it is installed correctly and used within its load-bearing capacity. While fiberglass is strong, exceeding its load limits can cause premature wear or damage. Regularly check for any signs of damage or excessive wear and replace sections if necessary.

Conclusion

Fiberglass catwalk grating offers a wealth of benefits for industrial, commercial, and marine applications. Its durability, safety features, and cost-effectiveness make it a valuable choice for environments that demand reliability and long-lasting performance. Whether it’s used for industrial walkways, marine platforms, or commercial spaces, fiberglass grating is designed to deliver excellent results while requiring minimal maintenance.

If you’re looking for a solution that combines strength, safety, and durability, fiberglass catwalk grating should be at the top of your list. Its versatility and ability to withstand harsh conditions make it the ideal choice for a wide range of projects. Invest in fiberglass catwalk grating today, and ensure that your operations are safer and more efficient for years to come.