Introduction

When embarking on a new project, selecting the right materials is crucial for success. Two common choices for structural components are fiberglass angle stock and aluminum. Each material has unique properties that make it suitable for different applications. This article will compare fiberglass angle stock and aluminum in various aspects to help you make an informed decision for your project.

fiberglass angle stock

Fiberglass Angle Stock vs. Aluminum

What is Fiberglass Angle Stock?

Fiberglass angle stock is a structural component made from a composite material consisting of fiberglass fibers and resin. It is known for its high strength-to-weight ratio, resistance to corrosion, and non-conductivity. These properties make fiberglass angle stock an excellent choice for certain applications.

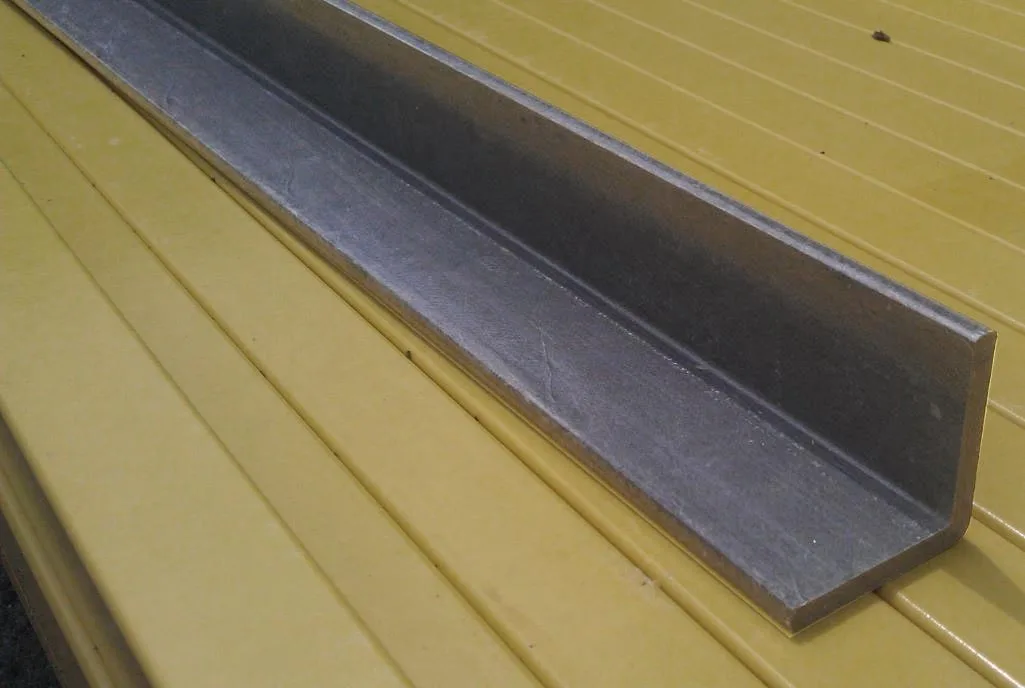

What is Aluminum Angle Stock?

Aluminum angle stock is a structural component made from aluminum, a lightweight and versatile metal. It is prized for its strength, corrosion resistance, and conductivity. Aluminum is widely used in various industries, including construction, automotive, and aerospace.

Strength and Durability

Fiberglass:

- High tensile strength

- Resistant to impacts and stress

- Non-corrosive, ideal for harsh environments

Aluminum:

- Strong but can be prone to bending under extreme stress

- Corrosion-resistant but can oxidize over time

- Durable and long-lasting with proper maintenance

Weight Considerations

Fiberglass:

- Lighter than aluminum

- Easier to handle and transport

- Reduces overall project weight

Aluminum:

- Heavier than fiberglass but still lightweight

- Provides stability and support

- Suitable for load-bearing applications

Cost Analysis

Fiberglass:

- Generally more expensive initially

- Lower maintenance costs over time

- Longer lifespan in corrosive environments

Aluminum:

- More affordable upfront

- Moderate maintenance costs

- Durable but may require replacements sooner in certain conditions

Corrosion Resistance

Fiberglass:

- Excellent resistance to moisture, chemicals, and UV radiation

- Ideal for outdoor and marine applications

Aluminum:

- Good resistance to rust and corrosion

- Can oxidize, forming a protective layer

- Requires treatment or coating in harsh environments

Electrical and Thermal Conductivity

Fiberglass:

- Non-conductive, safe for electrical applications

- Low thermal conductivity, good insulator

Aluminum:

- Conductive, suitable for electrical applications where grounding is necessary

- High thermal conductivity, used in heat exchangers and cooling systems

Installation and Fabrication

Fiberglass:

- Easy to cut, drill, and shape with standard tools

- Requires specific safety precautions due to fiberglass dust

- Lightweight, reducing installation effort

Aluminum:

- Easy to cut, weld, and fabricate

- Requires specialized tools for welding

- Heavier but manageable for most installations

Environmental Impact

Fiberglass:

- Produced from non-renewable resources

- Long-lasting, reducing the need for frequent replacements

- Difficult to recycle compared to metals

Aluminum:

- Highly recyclable, reducing environmental footprint

- Energy-intensive production process

- Long-lasting with proper recycling practices

Aesthetics and Appearance

Fiberglass:

- Available in various colors and finishes

- Can be painted or coated for enhanced appearance

Aluminum:

- Sleek, metallic finish

- Can be anodized or powder-coated for different colors

Application Suitability

Fiberglass:

- Ideal for corrosive environments like marine and chemical industries

- Suitable for electrical insulation and non-conductive requirements

Aluminum:

- Perfect for construction, automotive, and aerospace applications

- Suitable for projects requiring electrical conductivity and thermal management

Choosing the Right Material for Your Project

Assessing Project Requirements

Evaluate the specific needs of your project, such as strength, weight, corrosion resistance, and conductivity. Consider the environment in which the material will be used and any regulatory requirements.

Budget Considerations

Determine your budget for the project, including initial costs and long-term maintenance expenses. Factor in the lifespan of the material and any potential savings from reduced maintenance or replacements.

Environmental and Safety Factors

Consider the environmental impact of the materials and their safety for your specific application. Evaluate the ease of recycling and any potential hazards during installation and use.

Consultation with Experts

Consult with material experts or engineers to get professional advice on the best material for your project. They can provide insights based on experience and technical knowledge.

FAQs

What is the main advantage of fiberglass angle stock over aluminum?

Fiberglass angle stock offers superior corrosion resistance and is non-conductive, making it ideal for harsh environments and electrical applications.

Which material is more cost-effective for long-term use?

While fiberglass may have higher initial costs, its low maintenance requirements and long lifespan in corrosive environments can make it more cost-effective in the long run.

Can aluminum angle stock be used in marine applications?

Yes, aluminum angle stock can be used in marine applications, but it may require additional coatings or treatments to prevent corrosion.

Is fiberglass angle stock safe for electrical installations?

Yes, fiberglass angle stock is non-conductive and safe for electrical installations, providing insulation and reducing the risk of electrical hazards.

How does the weight of fiberglass compare to aluminum?

Fiberglass is generally lighter than aluminum, making it easier to handle and reducing the overall weight of the project.

Can fiberglass and aluminum be used together in the same project?

Yes, fiberglass and aluminum can be used together, but it’s important to consider their different properties and ensure they are compatible for the specific application.

Conclusion

Choosing between fiberglass angle stock and aluminum depends on various factors, including the specific requirements of your project, budget, and environmental considerations. Both materials have unique advantages that make them suitable for different applications. By understanding their properties and consulting with experts, you can make an informed decision that ensures the success of your project.