Introduction

Fiberglass angle stock is a versatile and durable material used in various DIY and construction projects. Its high strength-to-weight ratio, resistance to corrosion, and non-conductive properties make it ideal for applications where traditional materials like steel or aluminum may fall short. However, to ensure the longevity and stability of your structures, fastening fiberglass angle stock correctly is crucial.

In this guide, we’ll walk you through the process of fastening fiberglass angle stock effectively. Whether you’re a DIY enthusiast or tackling a small-scale construction project, these tips and steps will help you secure fiberglass angle stock with confidence, ensuring strong and durable results.

fastening fiberglass angle stock

What is Fiberglass Angle Stock?

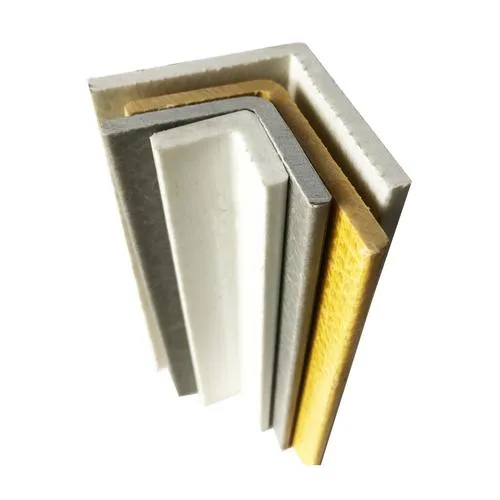

Fiberglass angle stock refers to structural shapes made from fiberglass-reinforced plastic (FRP). It is produced through a pultrusion process, resulting in high-strength, lightweight materials with excellent resistance to environmental conditions like moisture, chemicals, and UV radiation. The “angle” in its name comes from its 90-degree, L-shaped design, making it suitable for corner reinforcements, framing, and support applications.

Common uses for fiberglass angle stock include:

- Structural framing in construction

- Reinforcing beams and joints

- Outdoor structures exposed to harsh weather

- DIY projects, such as building shelves or frames

Compared to traditional metal angle stock, fiberglass is often preferred for its non-conductive properties, especially in electrical applications, and its resistance to rust and corrosion. Understanding these benefits helps DIYers and professionals alike appreciate the importance of proper fastening techniques to maintain these advantageous properties.

Tools and Materials Needed for Fastening Fiberglass Angle Stock

Before you begin your project, it’s important to gather the right tools and materials. Properly fastening fiberglass angle stock requires a careful selection of fasteners, tools, and accessories to avoid damage to the fiberglass and ensure a secure installation.

Here’s what you’ll need:

- Measuring Tape: Essential for measuring lengths of fiberglass angle stock to ensure precision.

- Saw or Cutter: A fine-toothed saw, such as a hacksaw, is ideal for cutting fiberglass without causing splintering.

- Drill: A variable-speed drill is necessary for drilling pilot holes in the fiberglass.

- Carbide-Tipped Drill Bits: Standard bits may dull or chip quickly, so carbide-tipped bits are recommended when working with fiberglass.

- Screws or Bolts: Stainless steel or coated screws are ideal for fastening fiberglass angle stock, as they resist corrosion.

- Washers and Nuts: When using bolts, washers and nuts help distribute pressure evenly and prevent damage to the fiberglass.

- Protective Gear: Fiberglass dust can be harmful, so always wear safety goggles, gloves, and a dust mask when cutting or drilling fiberglass.

Selecting the appropriate fasteners is crucial, as not all fasteners are compatible with fiberglass. Stainless steel screws or bolts work best because they are corrosion-resistant and do not react with the fiberglass material. Additionally, it’s important to drill pilot holes to prevent the fiberglass from cracking when the fasteners are inserted.

Step-by-Step Guide to Fastening Fiberglass Angle Stock

Now that you have your tools and materials ready, it’s time to dive into the step-by-step process of fastening fiberglass angle stock.

Step 1: Measuring and Cutting

Accurate measurement is the first step in any successful installation. Use a measuring tape to determine the length of fiberglass angle stock you’ll need. Mark the stock where you plan to cut, ensuring that the angle and length are precise.

When cutting fiberglass, it’s important to use a fine-toothed saw to avoid splintering. A hacksaw or a saw with carbide teeth works best for this purpose. As you cut, apply steady pressure and make sure the stock is securely clamped to prevent any shifting or movement that could cause uneven cuts.

Step 2: Drilling Holes

Drilling into fiberglass requires care to prevent cracking or splintering. Using carbide-tipped drill bits, which are designed to handle the hardness of fiberglass, start by drilling pilot holes where the fasteners will go.

A few tips to keep in mind:

- Use a low-speed setting on your drill to reduce heat, which can weaken the fiberglass.

- Apply even, gentle pressure when drilling, letting the bit do the work.

- Always drill pilot holes slightly smaller than the diameter of the screw or bolt to ensure a snug fit without putting excessive pressure on the fiberglass.

Step 3: Securing with Fasteners

Once the pilot holes are drilled, it’s time to insert your fasteners. Use stainless steel screws or bolts to secure the fiberglass angle stock. If you’re using bolts, place washers on both sides of the fiberglass to distribute the pressure evenly, preventing cracks or damage to the material.

When tightening the fasteners, avoid over-tightening. Fiberglass is strong, but excessive pressure can cause it to crack or weaken over time. A firm but gentle hand is all that’s needed to ensure a secure fit.

Step 4: Checking Stability

After fastening the fiberglass angle stock, it’s important to check the stability of the installation. Gently test the joint or frame to ensure that it is secure and does not wobble or shift. If necessary, adjust the fasteners or add additional supports to strengthen the structure.

By following these steps, you’ll have a solid, long-lasting installation that maximizes the durability and benefits of fiberglass angle stock.

Common Mistakes to Avoid

When working with fiberglass angle stock, even experienced DIYers can make mistakes that compromise the integrity of the material or the overall structure. Here are some common errors to watch out for and how to avoid them:

- Over-tightening Fasteners: This can cause the fiberglass to crack. Always tighten screws and bolts just enough to secure the material without applying excessive force.

- Using Incorrect Fasteners: Fiberglass requires specific types of screws and bolts, such as stainless steel, to avoid corrosion and damage.

- Skipping Pilot Holes: Drilling pilot holes is essential to prevent the fiberglass from cracking. Never try to drive screws directly into the material without pre-drilling.

- Poor Measurement and Cutting: Ensure that your measurements are precise and that you use the right tools to avoid splintering or uneven cuts.

By avoiding these common pitfalls, you’ll ensure a cleaner, more professional result in your DIY project.

Conclusion and Call to Action

Fastening fiberglass angle stock may seem intimidating at first, but by following the proper steps and using the right tools, you can achieve strong, durable installations in your DIY projects. From measuring and cutting to drilling and securing, each step plays a critical role in ensuring the success of your project.

Now that you’ve mastered the basics, it’s time to put these techniques to the test in your next DIY adventure! Whether you’re building a new frame or reinforcing an existing structure, these tips will help you achieve lasting, reliable results. Share your experience with us, and don’t forget to pass along these tips to fellow DIY enthusiasts!