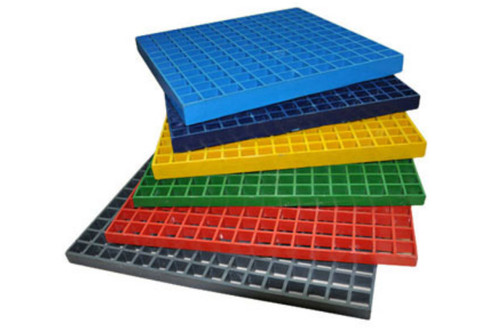

FRP grating is made of glass fiber and resin. Fiberglass gives strength to the finished product, while resin makes it resistant to corrosive substances. Glass fiber or fiberglass is an inorganic non-metallic material with particularly good performance.

What is the difference between molded FRP grating and pultruded FRP grating?

Fiberglass molded grating is a grating composed of horizontal and vertical layers of liquid resin and continuous fiberglass rovings. As the name suggests, it is made from a large metal mold. The multi-directional strength of molded fiberglass grating means that cuts that make room for ducts or complex floor layouts do not require additional reinforcement. Another advantage of molded FRP is that it comes in standard sizes and can be ordered in bulk and stored until needed.

Fiberglass pultruded grating uses a different manufacturing process. It takes resin and glass fibers, which are combined into a new composite material through a series of steps. It does not use molds, so there is more flexibility when creating different shapes and sizes. And often less waste. Pultruded FRP grating has a high glass-to-resin ratio, which increases its strength and span capacity.

- grating 4

- grating 3

There is also anti-corrosion fiberglass gratings. Due to the existence of corrosive liquids and gases, these areas are rapidly corroded by metals. What measures will be taken for the application of anti-corrosion layers, the corroded parts are still very amazing, not only causing harsh production environments , but also affect non-hazardous production, and sometimes even stop production, the structural material of FRP grating can play a very good effect in these fields, it has the advantages of long life, low cost, non-hazardous and reliable, and no maintenance.

The use of FRP Grating:

1. Fuel chemical industry: Because of the good corrosion resistance of FRP, it has satisfactory applications in fuel, water conservancy engineering, textile printing and dyeing, and food processing.

2. Electric power: Because of its excellent performance, extruded FRP trench covers are widely used as insulating support members, high-voltage cable trays, receiving antenna posts, and high-voltage current operating rods.

3. Transportation: FRP gutter cover is used for pressing branches and corner boards in trains and vehicles. Of course, it can also be used as high-speed road guardrail, sound-absorbing board and anti-glare board.

4. Construction: It can be used for roof support, construction of guardrails, doors and window frames.

- grating 1 1

- grating 2 1

For example: 38x38x38mm FRP gratings are often used in car washes.

Car wash FRP grating is a kind of unsaturated polyester resin (including m-benzene type, o-phthalic type, vinyl type and phenolic type, bisphenol A, etc.) It is a plate-like material with a certain opening rate made by a special process on a custom mold for the skeleton.

38x38x38mm FRP grating can also be used for trench cover