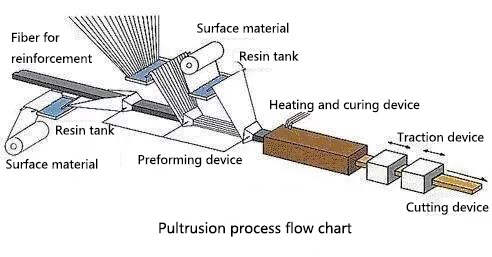

The composite material extrusion process is a process method for producing composite material profiles by infiltrating continuous fibers or their fabrics with resin under the traction of the traction equipment and heating the wax through the molding die to solidify the resin.

Typical process flow of pultrusion

Fiber roving arrangement → dipping → preforming → extrusion molding and curing → drawing → cutting → product

Composition of pultrusion equipment

- Reinforcing material conveying system: such as creel, felt spreading device, yarn hole, etc.

- Resin impregnation: The straight groove impregnation method is most commonly used, and the fibers and mats should be arranged neatly throughout the impregnation process.

- Performing: The impregnated reinforcement material is carefully passed through a performing unit in a continuous manner to ensure their relative position, gradually approaching the final shape of the article, and extruding excess resin before entering the mold for forming and curing.

- Mold: The mold is designed under the conditions determined by the system. According to the resin curing exothermic curve and the friction properties of the material and the mold, the mold is divided into three different heating zones, the temperature of which is determined by the performance of the resin system. The die is the most critical part of the extrusion process, and the length of a typical die ranges from 0.6 to 1.2 m.

- Traction: The traction itself can be a crawler-type puller or two reciprocating grippers to ensure continuous motion.

- Cutting device: The profile is cut to the required length by an automatic synchronously moving cutting saw.

The process flow of pultrusion technology can be briefly divided into three steps: infiltration, forming, and curing/cooling.

Advantages of pultrusion

The main advantages compared to other composite production technologies are as follows:

1. High utilization rate of raw materials

Compared with the traditional lay-up technology, pultrusion technology does not need to cut on the sheet fiber material or prepreg and directly uses the raw yarn and prepreg tape for production, except that there are small parts at both ends of the profile that need to be cut off (cut off) The length depends on the length of the initial pulling fiber and the length of the curing mold), and no other waste is generated during the production process.

2. Can produce complex structural profiles

The technology suitable for profile production in the engineering field includes winding technology and weaving technology. Due to the limitation of the working principle, the above two technologies can only produce single-cavity simple section profiles, and it is relatively difficult to arrange longitudinal reinforcing fibers. However, pultrusion technology is temporarily unable to effectively produce variable-section profiles.

3. High production efficiency:

Pultrusion technology is automated or semi-automatic assembly line production, with both “forming” and “curing” functions, enabling continuous production. The pultrusion speed can reach 10 meters per minute, which is unmatched by other “form-cure” fiber composite production technologies.

4. Good quality

Through automated equipment, process parameters such as profile traction, longitudinal preload, winding/weaving preload, mold temperature distribution, resin injection pressure, and pultrusion speed can be precisely controlled in the production process to ensure overall quality uniformity. and controllability. In addition, when the profile is cured, it is covered by the outer mold. After curing, the overall dimensional tolerance of the profile is small and the surface quality is high.

5. High flexibility

By using different fiber materials and substrates (such as ultra-high modulus unidirectional fibers or multiaxial fibers, thermosetting resins or thermoplastic resins, etc.) extrusion technology can produce products with different applicability according to different needs.

6. Strong expansion/replication

By using the same molds, process parameters, and raw materials, it is possible to quickly expand the production line or replicate it in other regions while maintaining the same quality. High-volume, high-quality profiles can be produced without the need for experienced layup workers or high-cost autoclave equipment.

Application of pultrusion products

Pultruded products include various rods, plates, hollow tubes, and profiles, with a wide range of applications, including the following aspects:

1. Electric Market

This is the earliest market for pultrusion applications. The products that have been successfully developed and applied are cable trays, ladder frames, brackets, insulating ladders, transformer isolation bars, motor slot wedges, street lamp posts, third rail guards for electric railways, and optical fiber cables. Core material, etc. There are many products in this market that deserve our further development.

2. Chemical and anti-corrosion markets

Chemical anti-corrosion is a major user of pultrusion. Successful applications include FRP sucker rods, cooling tower brackets, offshore oil production equipment platforms, walking grating, stair handrails and brackets, structural brackets in various chemically corrosive environments, water treatment plant cover, etc.

3. Consumer entertainment market

This is a huge potential market, and the current development and application are fishing rods, tent poles, umbrella frames, flagpoles, tool handles, lighting poles, railings, handrails, stairs, radio antennas, and marinas, garden tools, and accessories.

4. Construction market

In the construction market, pultrusion has penetrated into the market of traditional materials, such as doors and windows, concrete formwork, scaffolding, stair handrails, house partition wall panels, rebar materials, decorative materials, etc. It is worth noting that there will be a lot of room for improvement in FRP rebar materials and decorative materials.

5. Road traffic market

Successful applications include isolation fences on both sides of expressways, road signs, pedestrian bridges, sound insulation walls, refrigerated truck components, etc.

6. Wind power market

In the field of wind power, the pultrusion process is mainly used to form composite material sheets of a certain thickness, and then the blade main beam is formed on the mold by vacuum infusion or prepreg process; In the corresponding position of the body, it is integrally poured with the shell. Compared with other technologies, the pultruded sheet main beam laying technology has the characteristics of high efficiency, small quality fluctuation, and low cost, which can effectively improve the strength and modulus of the product, which is a trend in the development of blade main beam in the future.