The production process control of FRP pultruded profiles, molded grating, hand lay-up products, and other FRP products seems to be extensive and simple, but it actually requires strong professional knowledge and production experience as technical support to produce qualified FRP products.

Common Quality Defects in FRP Pultrusion Process:

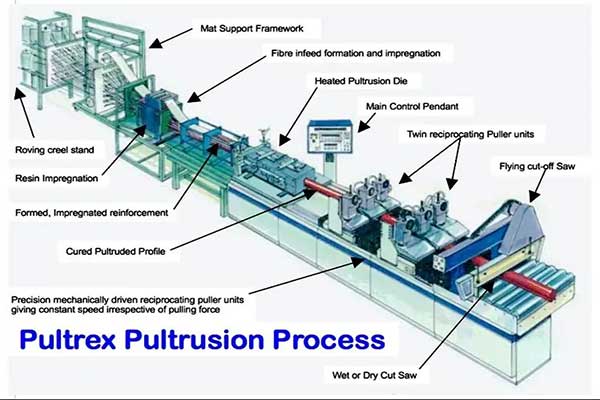

Pultrusion Process

1. Bubble:

During the production of FRP products, due to the excessive amount of resin, excessive resin viscosity, improper selection of glass fibers, and lack of compression of the glass fiber cloth, a large number of air bubbles will be generated in the mold cavity, which will affect the product. surface roughness.

2. Layering:

Delamination is due to insufficient resin usage, heating and curing of glass fiber without sufficient resin penetration, or excessive heating temperature, which will cause delamination of FRP products.

3. Crack:

The crack on the surface of FRP products is because the resin layer of unsaturated polyester resin on the surface of the product is too thick, and there is no glass fiber or fiber cloth to play the role of connecting stress, so it is easy to cause the product to crack after being stressed.